Preparation method and application of menthol derivative, mixture thereof and menthol derivative

A technology of menthol derivatives and mixtures, applied in mint substances and their preparation methods, and in the field of cultural relics reinforcement, can solve the problems of insufficient strength of reinforced cultural relics, difficulty in maintaining the shape of reinforced cultural relics, toxicity, etc., and achieve application Broad, controlled removal, high melting temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

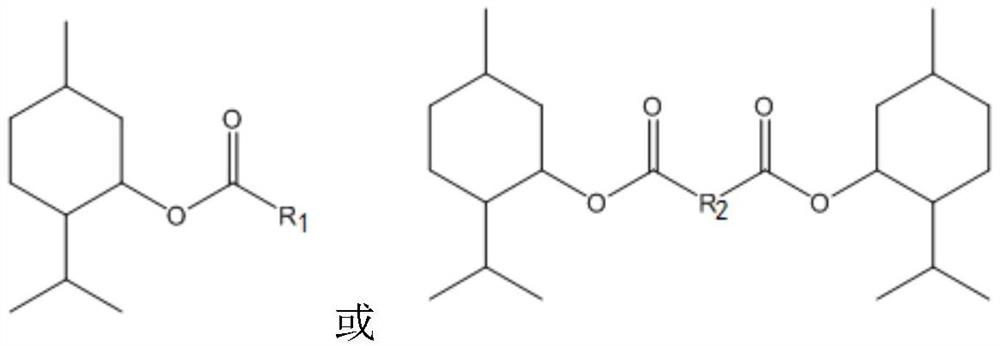

Method used

Image

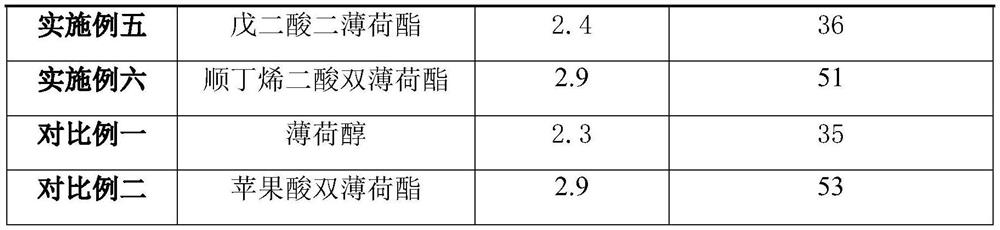

Examples

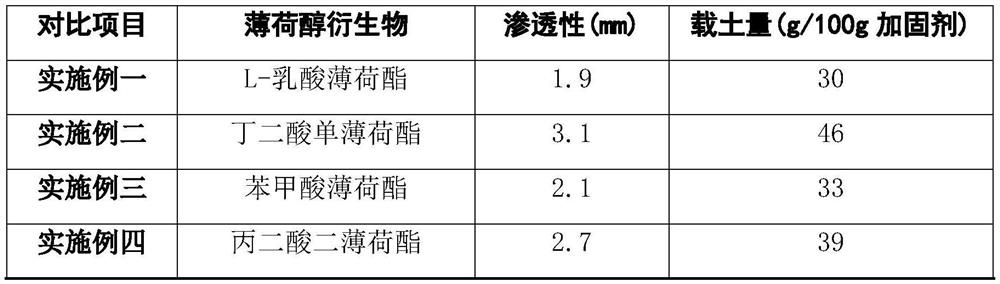

Embodiment 1

[0042] In this embodiment, a method for preparing L-menthol lactic acid adopts a menthol esterification modification process to prepare menthol esterification-modified derivatives, including the following steps:

[0043] (1) Batching process: adopt menthol and L-lactic acid as raw materials, adopt cyclohexane as solvent, adopt p-toluenesulfonic acid as catalyst, take by weighing 85g of L-lactic acid whose mass percentage content is 90%, add cyclohexane 2L, Add 156g of menthol, 5g of p-toluenesulfonic acid, and mix menthol, L-lactic acid, cyclohexane and p-toluenesulfonic acid in the reactor to form a reactant system mixture;

[0044] (2) carry out menthol esterification reaction in reactor, control the reaction temperature of the reactant system mixture in said step (1) to be 95 ℃ above the solvent boiling point temperature, heat to reflux with water, and the reaction time is 6h; Embodiment Menthol esterification is carried out in solution;

[0045] (3) After the esterificati...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, especially in that:

[0055] In the present embodiment, a kind of preparation method of monomenthyl succinate adopts the menthol esterification modification process, prepares the menthol esterification modified derivative, comprises the following steps:

[0056] (1) batching process: adopt menthol and succinic anhydride as raw material, adopt chloroform as solvent, adopt DMAP as catalyst, take succinic anhydride 150g, add chloroform 1.5L, add 156g menthol, catalyst DMAP 12g, mix menthol, Succinic anhydride, chloroform and DMAP are mixed in a reactor to form a reactant system mixture;

[0057] (2) carry out menthol esterification reaction in reactor, control the reaction temperature of the reactant system mixture in described step (1) to be 80 ℃ above the solvent boiling point temperature, heat and reflux with water, and the reaction time is 12h; Embodiment Menthol esterification is carried out in solution;

[0058...

Embodiment 3

[0066] This embodiment is basically the same as the previous embodiment, and the special features are:

[0067] A kind of preparation method of menthyl benzoate adopts menthol esterification modification process, prepares the derivative of menthol esterification modification, comprises the steps:

[0068] (1) Ingredients process: using menthol, benzoyl chloride, NaHCO 3 As raw material, adopt DCM as solvent, adopt DMAP as catalyst, weigh the NaHCO of benzoyl chloride 155g and 74g 3 , add DCM to 1.5L, add 156g menthol, catalyst DMAP to 12g, menthol, benzoyl chloride, NaHCO 3 , DCM and DMAP are mixed in the reactor to form a reactant system mixture;

[0069] (2) carry out menthol esterification reaction in reactor, control the reaction temperature of the reactant system mixture in described step (1) to be 90 ℃, heat to reflux with water, the reaction time is 20h; Present embodiment menthol The esterification reaction is carried out in solution;

[0070] (3) After the esterif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com