A kind of micro-nano silver/polymer conductive composite material and its preparation method and application

A polymer conductive and composite material technology, which is applied in the field of micro-nano silver/polymer conductive composite materials and its preparation, can solve the problems of complex preparation methods and poor dispersion of silver powder, and achieve simple and easy preparation methods and excellent electrical conductivity. Excellent performance and particle size controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

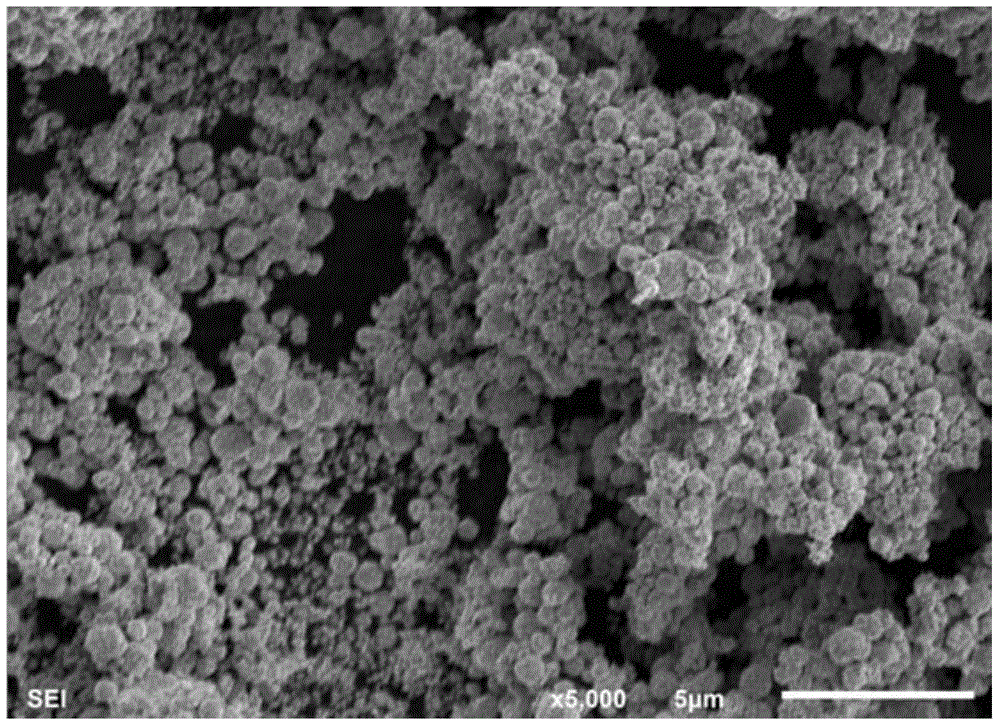

Embodiment 1

[0031] (1) Dissolve silver nitrate in 100 times the mass of deionized water, heat to 60°C, add ammonia water dropwise, stop the dropwise addition when the produced precipitate is just completely dissolved and the solution is clear, to obtain silver ammonia solution, add it to the silver ammonia solution Add silver nitrate mass 3% surfactant sodium lauryl sulfate and mix evenly to obtain an emulsion, then add the reducing agent solution dropwise under stirring conditions, the reducing agent solution consists of 0.08mol / L potassium borohydride aqueous solution and 0.3mol / L The ascorbic acid aqueous solution is obtained by mixing potassium borohydride and ascorbic acid in a ratio of 1:1, and the ratio of the amount of reducing agent in the reducing agent solution to the amount of silver ion in the silver ammonia solution is 1:1. After the agent solution is added dropwise, continue to stir and react for 60 minutes, wash and separate the precipitate, and obtain micronano silver powd...

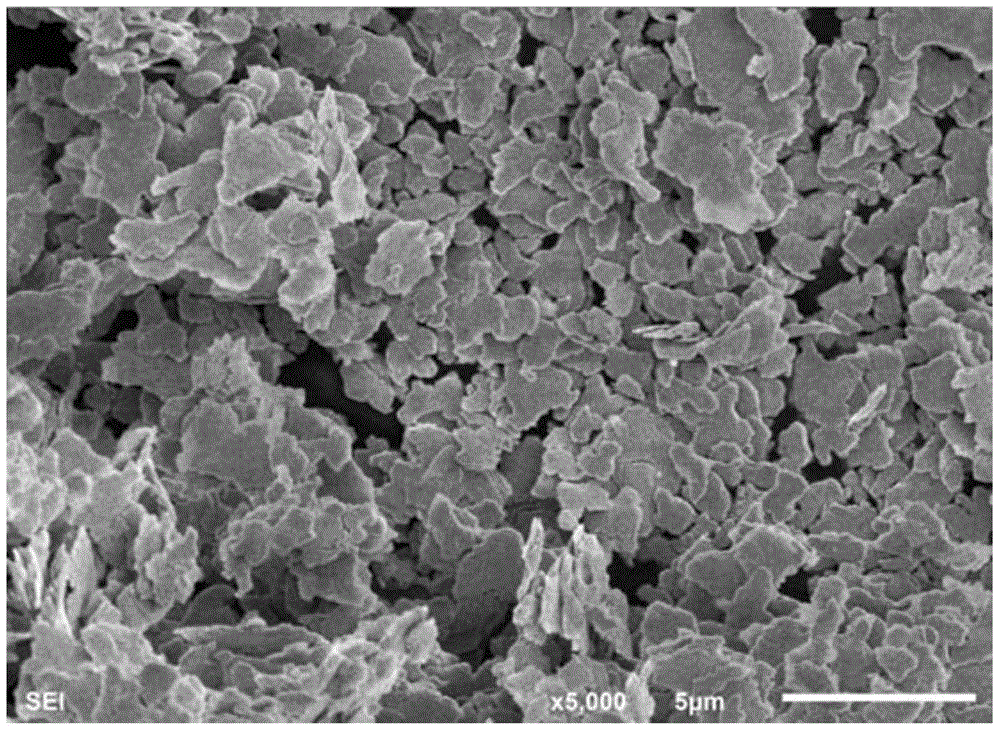

Embodiment 2

[0036] (1) Dissolve silver nitrate in 100 times the mass of deionized water, heat to 50°C, add ammonia water dropwise, stop the dropwise addition when the produced precipitate is just completely dissolved and the solution is clear, to obtain a silver ammonia solution, and pour it into the silver ammonia solution Add silver nitrate mass 5% surfactant sodium lauryl sulfate and mix evenly to obtain an emulsion, then add the reducing agent solution dropwise under stirring conditions, the reducing agent solution consists of 0.05mol / L potassium borohydride aqueous solution and 0.1mol / L The ascorbic acid aqueous solution is obtained by mixing potassium borohydride and ascorbic acid in a ratio of 1:1, and the ratio of the amount of reducing agent in the reducing agent solution to the amount of silver ion in the silver ammonia solution is 1:2. After the addition of the agent solution is completed, continue to stir and react for 30 minutes, wash and separate the precipitate, and obtain m...

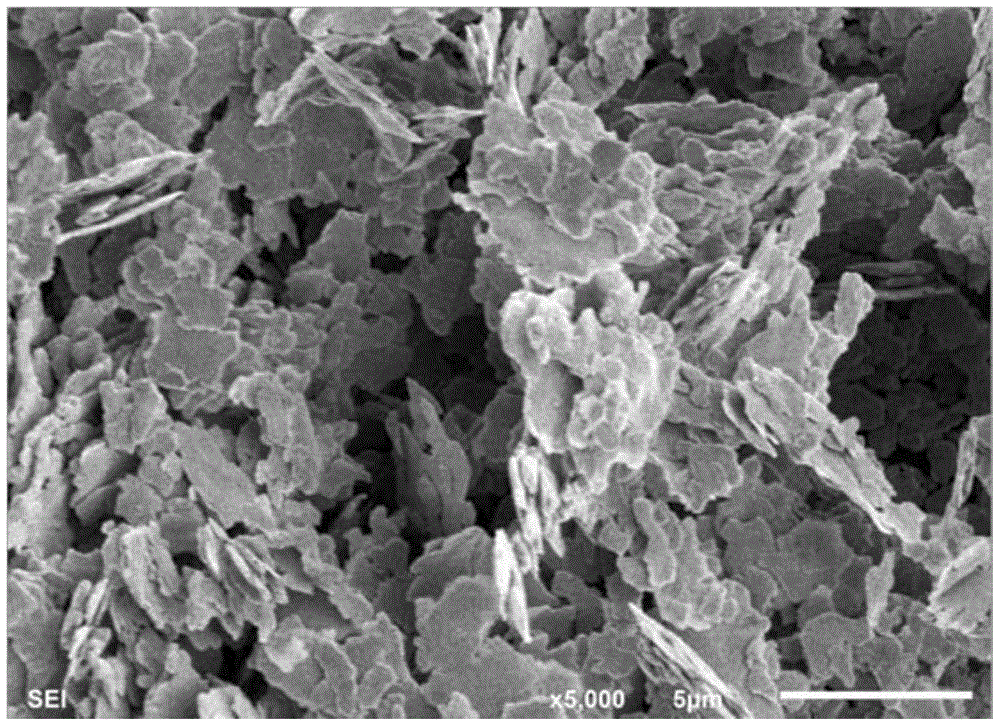

Embodiment 3

[0040] (1) Dissolve silver nitrate in 100 times the mass of deionized water, heat to 80°C, add ammonia water dropwise, stop the dropwise addition when the generated precipitate is just completely dissolved and the solution is clear, to obtain a silver ammonia solution, add it to the silver ammonia solution Add silver nitrate mass 1% surfactant sodium dodecylsulfonate and mix evenly to obtain an emulsion, then add the reducing agent solution dropwise under stirring conditions, the reducing agent solution consists of 0.1mol / L potassium borohydride aqueous solution and 0.5mol / L The ascorbic acid aqueous solution of L is obtained by mixing potassium borohydride and ascorbic acid at a ratio of 1:1, and the ratio of the amount of reducing agent in the reducing agent solution to the amount of silver ion in the silver ammonia solution is 1:0.5. After the reducing agent solution is added dropwise, continue to stir and react for 40 minutes, wash and separate the precipitate, and obtain m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com