Catalyst for catalytic cracking gasoline hydrodesulfurization and preparation method thereof

A technology for catalytic cracking gasoline and hydrodesulfurization, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. The effect of improving hydrodesulfurization selectivity, good particle size controllability, and good desulfurization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

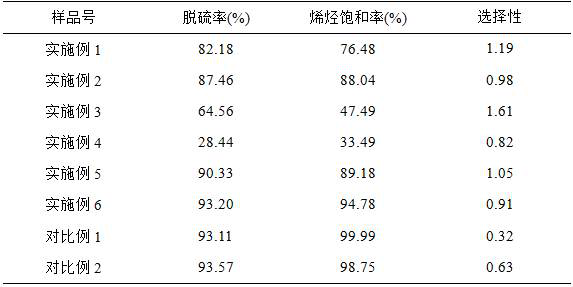

Embodiment 1

[0026] Mix 100 g pseudo-boehmite, 4.0 g field green powder, 5.0 g HNO 3 and 75 g of deionized water were put into a kneader and kneaded into a block, then put into an extruder, extruded using a clover template with a diameter of 2.0 mm, and then dried at a temperature of 65°C for 4 h, and then dried at a temperature of 500°C Calcined under the condition of 4 h to get Al 2 o 3 carrier.

[0027] According to 3wt%Co 3 o 4 content, a certain amount of cobalt acetate was dissolved in 70 mL of ammonia water to prepare a solution, which was impregnated in Al by equal volume method 2 o 3 supported, aged for 12 h, dried at 65°C for 4 h, and calcined at 500°C for 4 h to obtain Co 3 o 4 / γ-Al 2 o 3 Precursor.

[0028] According to 12wt%MoO 3 content and the molar ratio of S:Mo=4:1, dissolving ammonium heptamolybdate in an appropriate amount of ammonia water, then adding a certain amount of ammonium sulfide solution with a concentration of 20%, and reacting at 100°C for 1.0 h, ...

Embodiment 2

[0032] The preparation process is the same as in Example 1, and what is different from Example 1 is that the sulfur-containing compound is changed from ammonium sulfide to diethyl tetrasulfide; the synthesis temperature of ammonium tetrathiomolybdate is increased from 100°C to 130°C; The steaming temperature was reduced from 65°C to 60°C.

Embodiment 3

[0034] The preparation process was the same as in Example 1, except that the preparation temperature of ammonium tetrathiomolybdate was reduced from 100°C to 80°C, and the rotary evaporation temperature was reduced from 65°C to 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com