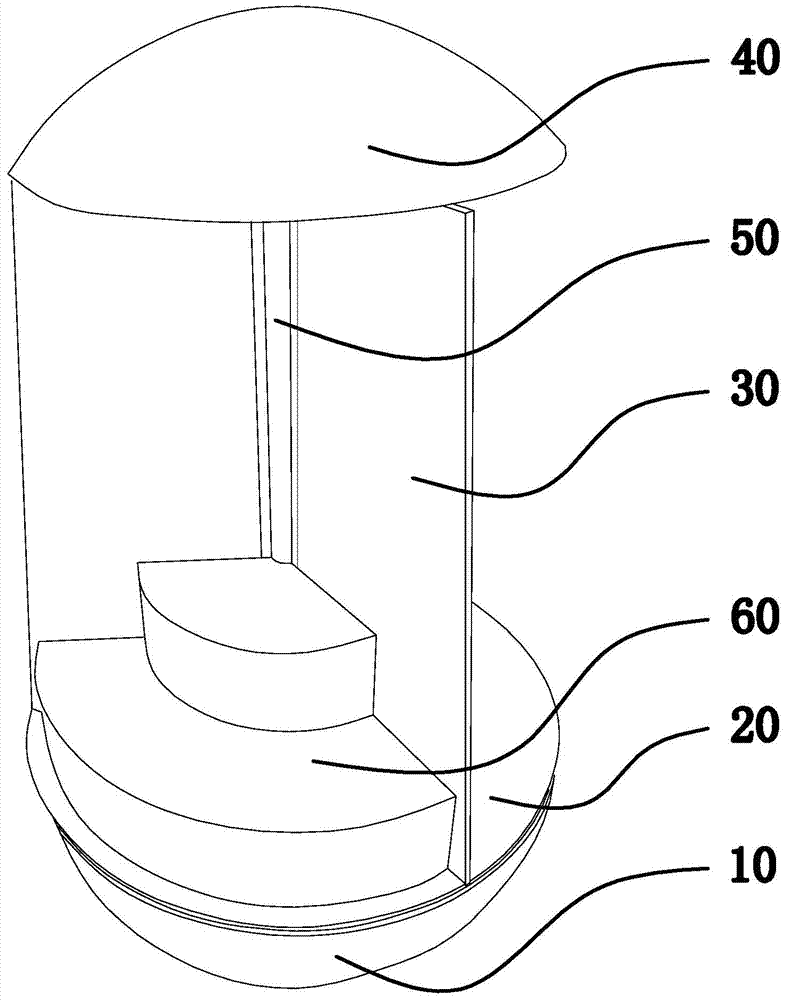

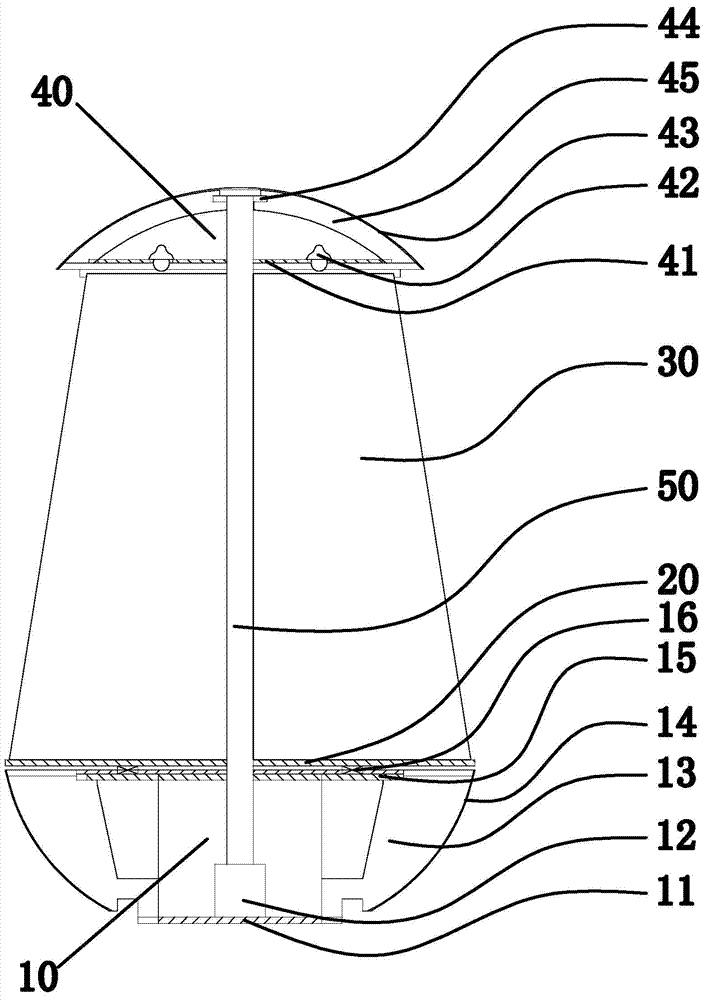

Automatic rotating exhibition stand

A technology of automatic rotation and exhibition stand, which is applied in the direction of display stands, display cabinets, display hangers, etc., can solve the problems of insufficient novel design, troublesome installation and adjustment, and inconvenient assembly, so as to improve the decorative effect, simple adjustment, and upgrade safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

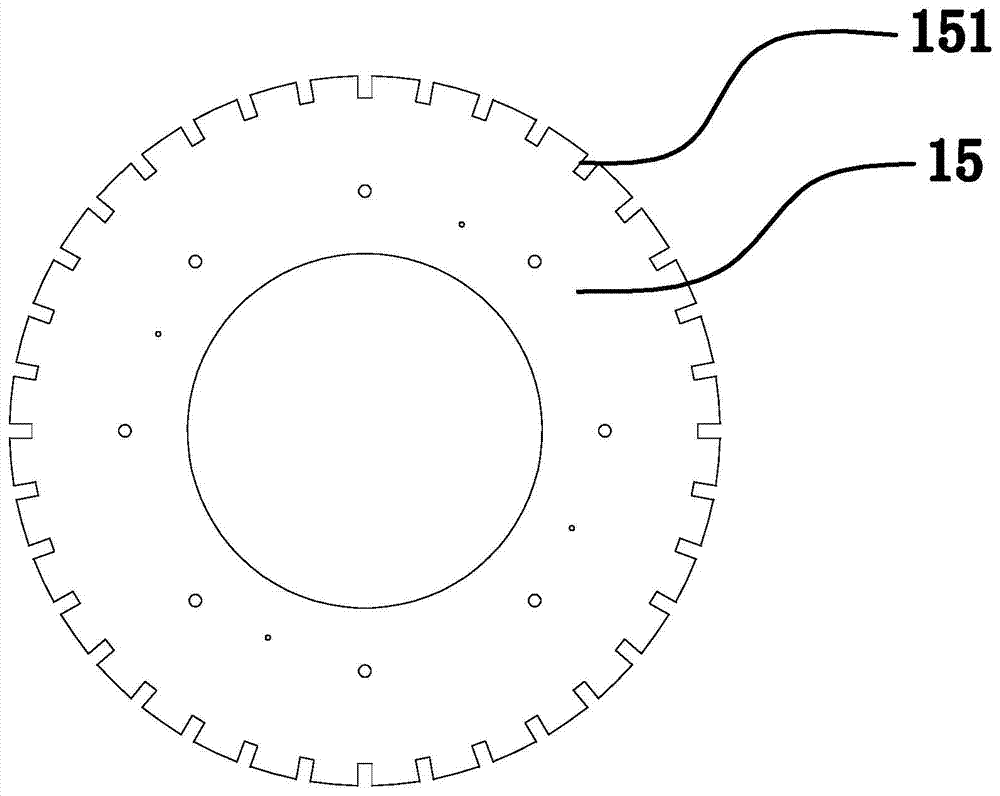

[0049] Example 1: Spray and adhere a flame-retardant fluorescent surface coating with a four-layer structure on the outer surface of the booth. The specific preparation method is as follows: the surface of the booth is pretreated by polishing, and the epoxy ester primer is electrostatically sprayed on the surface of the booth. , dried at 50°C for 5 minutes to form a primer layer 31 with a layer thickness of 1 mm; then cut the non-woven fabric according to the shape and size of the booth, arrange the cut non-woven fabric on the primer layer 31, and use epoxy ester The non-woven fabric is adhered to the surface of the primer layer 31, and after drying at 70°C for 10 minutes, a flame-retardant and heat-insulating layer 32 with a layer thickness of 2mm is formed; then the active calcium carbonate, Fluorescent powder and epoxy ester colored paint are mixed evenly and sprayed onto the flame-retardant heat-insulating layer 32 by electrostatic spraying. After drying at 50°C for 15 minu...

Embodiment 2

[0050] Example 2: Spray and adhere a flame-retardant fluorescent surface coating with a four-layer structure on the outer surface of the booth in sequence. The specific preparation method is as follows: the surface of the booth is pretreated by polishing, and the epoxy ester primer is electrostatically sprayed on the surface of the booth. , dried at 55°C for 8 minutes to form a primer layer 31 with a layer thickness of 2 mm; then cut the non-woven fabric according to the shape and size of the booth, arrange the cut non-woven fabric on the primer layer 31, and use epoxy ester The non-woven fabric is adhered to the surface of the primer layer 31, and after drying at 55°C for 8 minutes, a flame-retardant and heat-insulating layer 32 with a layer thickness of 3mm is formed; then the active calcium carbonate, Fluorescent powder and epoxy ester colored paint are mixed evenly and sprayed onto the flame-retardant heat-insulating layer 32 by electrostatic spraying. After drying at 55°C ...

Embodiment 3

[0051] Example 3: Spray and adhere a flame-retardant fluorescent surface coating with a four-layer structure on the outer surface of the booth in sequence. The specific preparation method is as follows: the surface of the booth is pretreated by polishing, and the epoxy ester primer is electrostatically sprayed on the surface of the booth. , dried at 60°C for 10 minutes to form a primer layer 31 with a layer thickness of 3 mm; then cut the non-woven fabric according to the shape and size of the booth, arrange the cut non-woven fabric on the primer layer 31, and use epoxy ester The non-woven fabric is adhered to the surface of the primer layer 31, and after drying at 60°C for 15 minutes, a flame-retardant and heat-insulating layer 32 with a layer thickness of 2mm is formed; then the active calcium carbonate, Fluorescent powder and epoxy ester colored paint are mixed evenly and sprayed onto the flame-retardant heat-insulating layer 32 by electrostatic spraying. After drying at 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com