Patents

Literature

52results about How to "Moderate grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

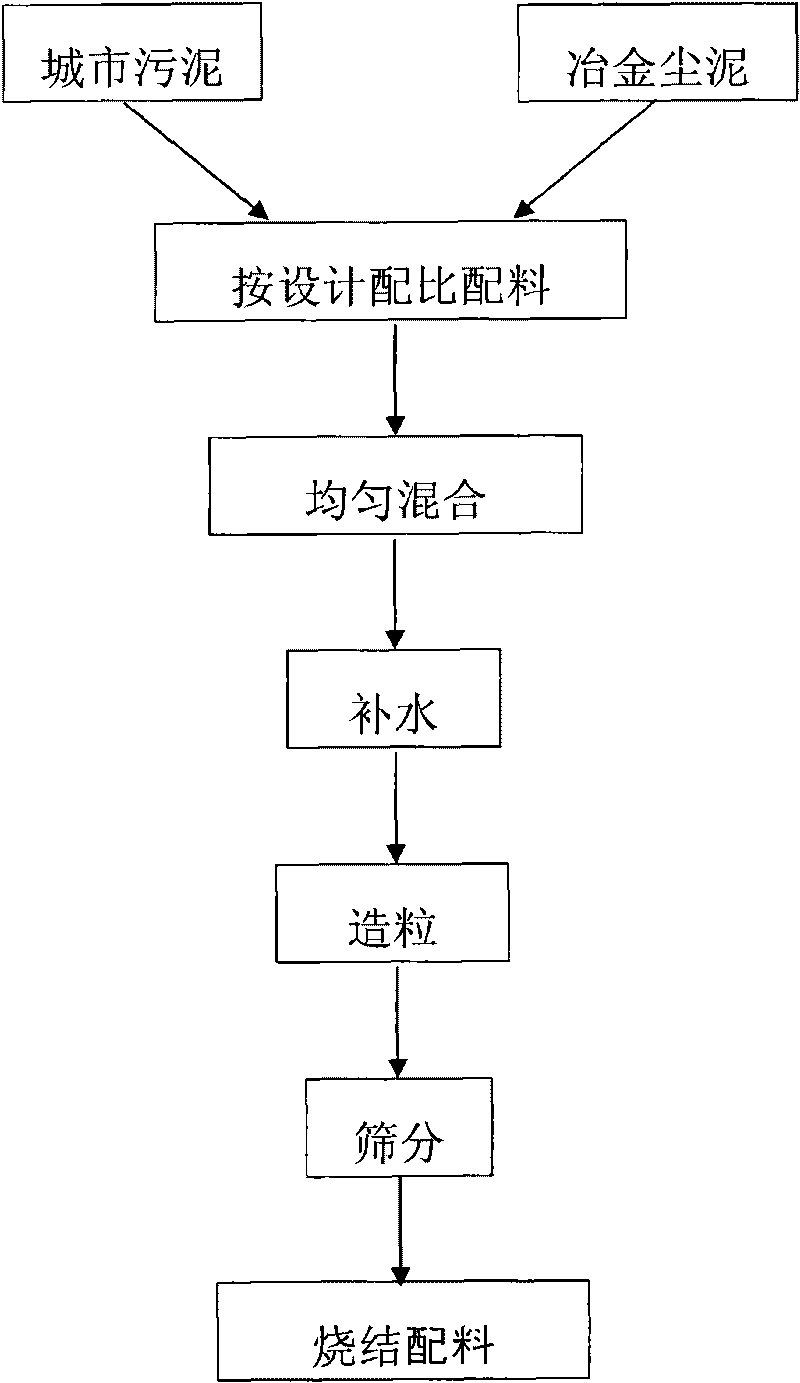

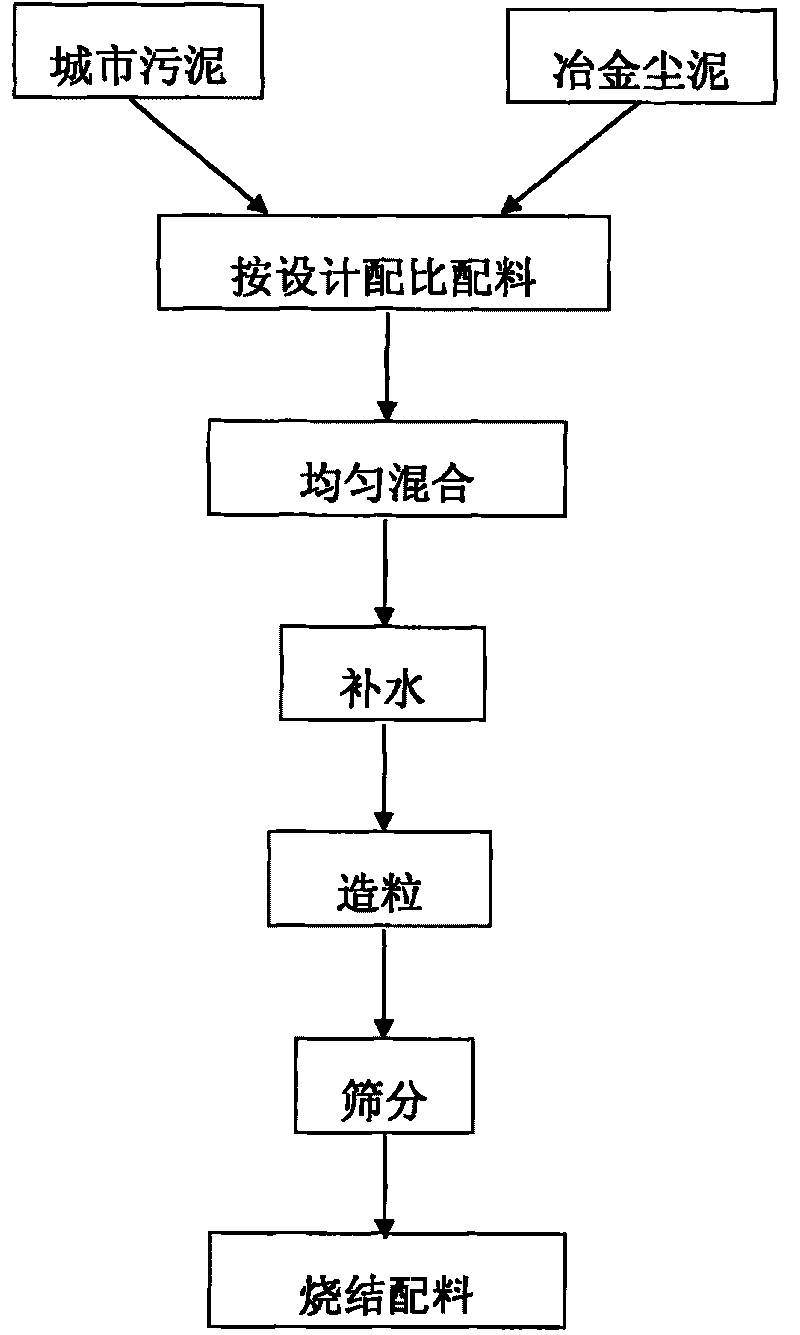

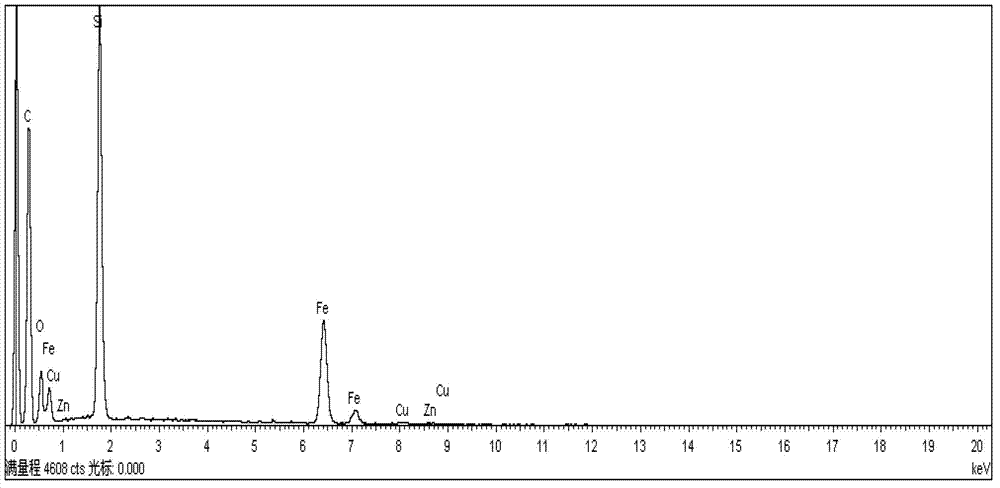

Method for preparing sintered mixture from municipal sludge and ferrous iron containing metallurgical dust

ActiveCN101717853ARealize unified utilizationEfficient recyclingProcess efficiency improvementSludgeNew energy

The invention relates to a method for preparing a sintered mixture from municipal sludge and iron containing metallurgical dust, which belongs to the technical field of resource recycling of the municipal sludge and the iron containing metallurgical dust. The method comprises the following steps of: preparing raw materials from 5-50 percent by weight of municipal sludge and 50-95 percent by weight of iron containing metallurgical dust, adding 0-20 percent by weight of water into the raw materials, then mixing and granulating to produce a sintered granular material, and using the sintered granular material as the mixture to be mixed into a sintering working procedure, wherein the proportion mixed into the sintering working procedure is 0.5-10 percent by weight of the total sintered raw materials quality. The method has the advantages that the processing flow of the municipal sludge is transferred to the mature sintering process flow of ferrous metallurgy, avoiding the problems of new energy consumption, secondary pollution and the like caused in traditional landfill and sintering processes of the municipal sludge, thereby recycling effective elements in the metallurgical dust and the municipal sludge in the steel production flow, improving sintering production process conditions to a certain degree and improving the sintering production efficiency.

Owner:SHOUGANG ENVIRONMENTAL IND +1

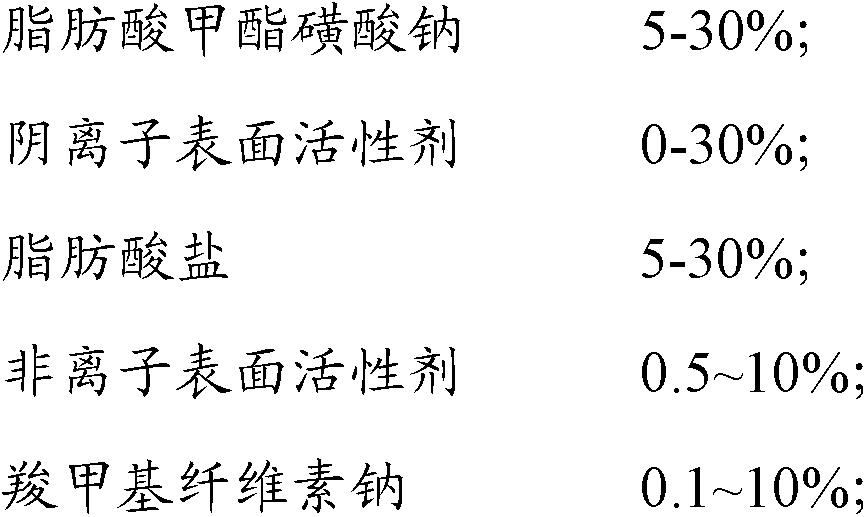

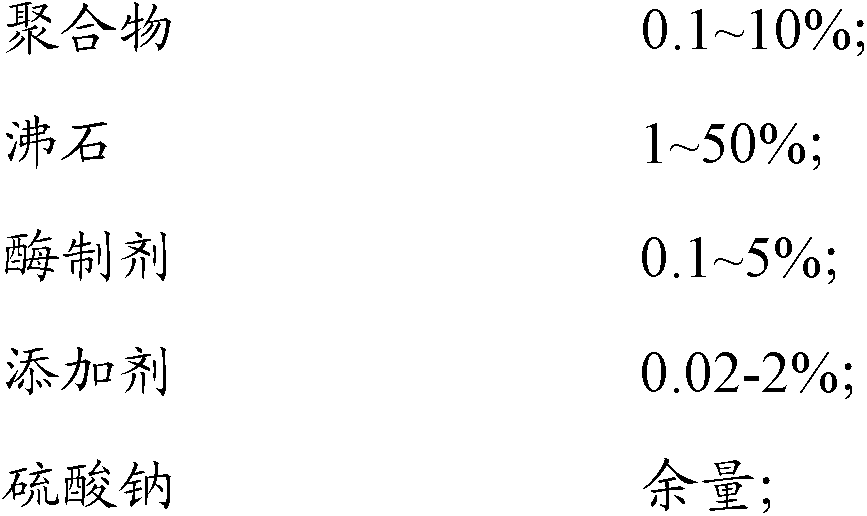

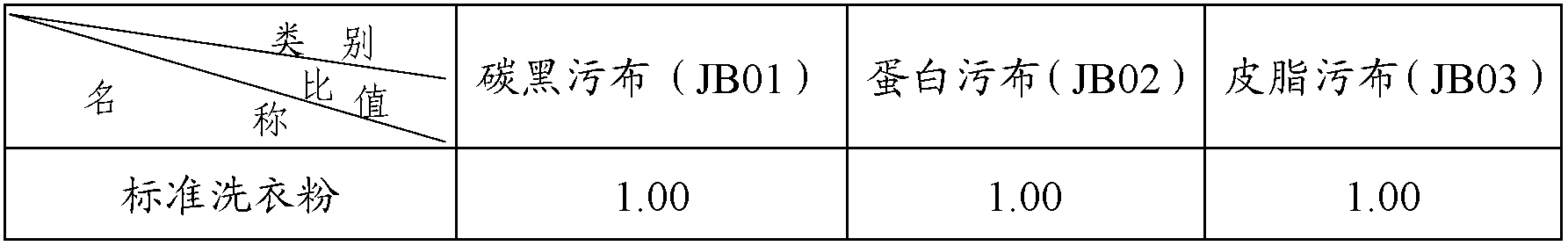

Soap powder composition containing sodium fatty acid methyl ester sulfonate and preparation method thereof

ActiveCN103320236AExcellent decontaminationImprove liquidityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSolubilityEthylene Homopolymers

The invention discloses a soap powder composition containing sodium fatty acid methyl ester sulfonate and a preparation method thereof. The soap powder composition comprises the following components in percentage by weight: 5-30% of sodium fatty acid methyl ester sulfonate, 0-30% of anionic surfactant, 5-30% of fatty acid salt, 0.5-10% of nonionic surfactant, 0.1-10% of sodium carboxymethyl cellulose, 0.1-10% of polymer, 1-50% of zeolite, 0.1-5% of enzyme preparation, 0.02-2% of additive and the balance of sodium sulfate. The polymer comprises one or combination of more of acrylic acid homopolymer, maleic acid-acrylic acid copolymer and acrylic acid-styrene copolymer. No sodium silicate or any other alkaline assistant is added into the soap powder composition, the free alkali in the system is lower than 0.5%, and the MES stability is high; and the soap powder has the advantages of favorable low-temperature solubility and the like, and is milder for the human body.

Owner:纳爱斯成都有限责任公司

Face washing salt sand and preparation method thereof

ActiveCN103027884AModerate grainModerate granularityCosmetic preparationsToilet preparationsBlackheadsMedicine

The invention discloses face washing salt sand and a preparation method thereof, and aims to overcome the defects that the conventional salt is mainly used for eating and has single function. The face washing salt sand comprises the following components in parts by weight: 80 to 90 parts of sea salt wrapped with Chinese medicinal extract, 10 to 15 parts of Chinese yam powder, 1 to 1.5 parts of bletilla powder, 1 to 3 parts of pearl powder, 0.2 to 0.5 part of aloe powder, 0.1 to 0.2 part of jojoba oil, and 0.1 to 0.3 part of glycerol. The face washing salt sand has the effects of cleaning, nutrition, skin protection and the like, and can be used for diminishing inflammation, removing acne, removing blackhead, reducing pores, clearing the pores, removing keratin, fading trails left by the acne and moisturizing, whitening and smoothing the skin; and the application range of the salt is widened, and the function of the salt is enriched.

Owner:ZHEJIANG BLUE STARFISH SALT PROD CO LTD

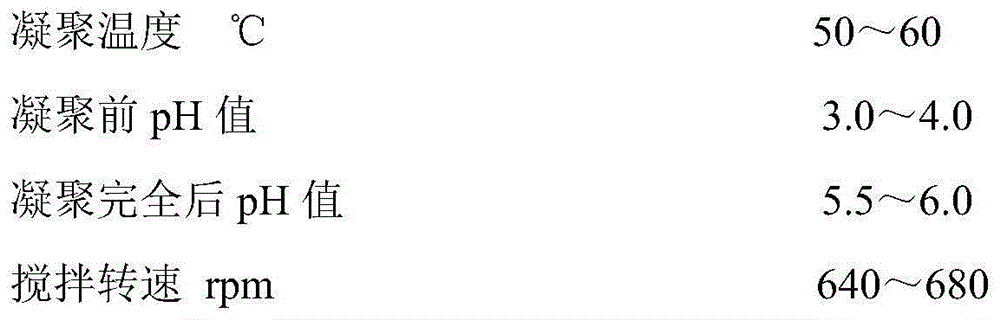

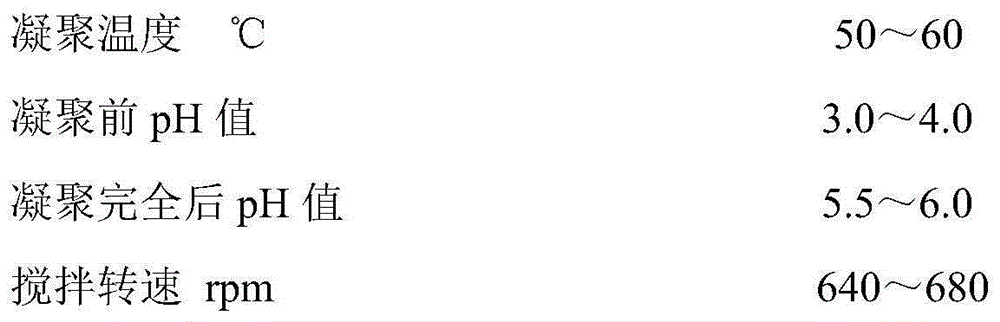

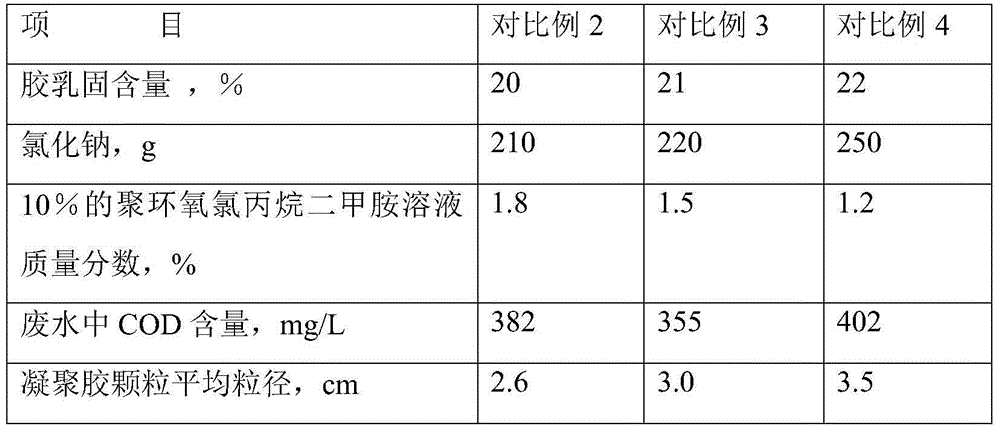

Ternary integrated rubber latex agglomeration process

The present invention relates to a ternary integrated rubber latex agglomeration process, and belongs to the technical field of synthetic rubbers. According to the agglomeration process, a ternary integrated rubber latex is adopted as a raw material, sulfuric acid is adopted as a pH value adjusting agent, an ammonium sulfate aqueous solution is adopted as an agglomeration mother liquor, and a poly epichlorohydrin-dimethylamine and cellulose derivative complex is adopted as an agglomeration agent; and the steps comprise: adding the agglomeration agent to the agglomeration mother liquor, adding the raw material, adding the pH value adjusting agent, and carrying out agglomeration. According to the present invention, the composite agglomeration agent is used, such that the COD content in the production wastewater can be reduced during the ternary integrated rubber production; the composite agglomeration agent has good water solubility, and can be used within a wide pH value range; the particle size of the colloidal particles after the agglomeration is moderate, the average particle size is 0.5-2 cm, and the drying is easily achieved; and the metal-ion-free ammonium sulfate electrolyte is adopted as the agglomeration mother liquor, such that the ternary integrated rubber with characteristics of low metal ion content and low corrosion on metals can be produced.

Owner:CHINA PETROLEUM & CHEM CORP

Cold roll with thick quench-hardened layer and manufacturing method thereof

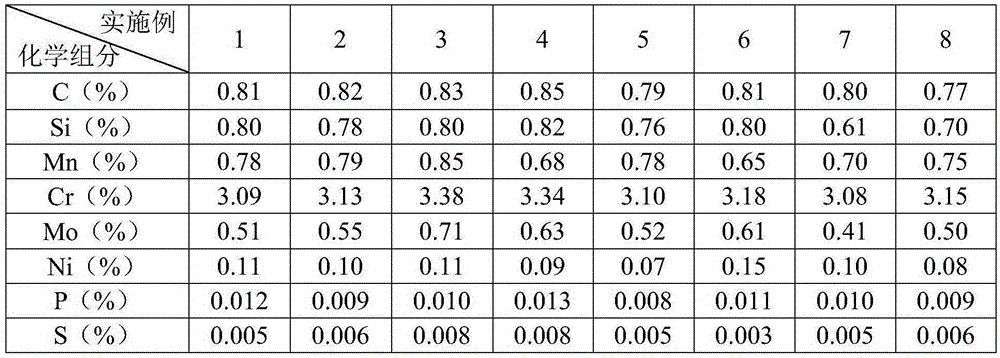

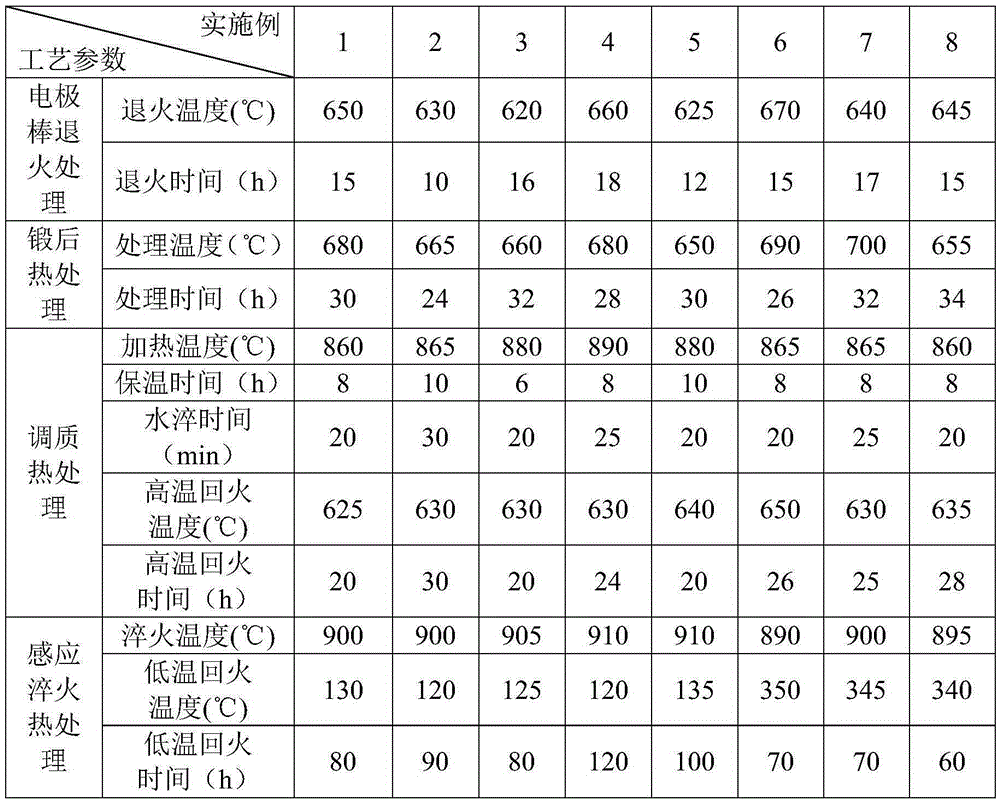

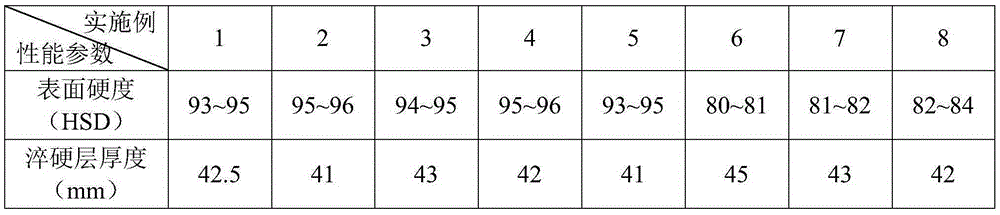

ActiveCN105316582AIncreasing the thicknessThe thickness of the hardened layer is increasedIncreasing energy efficiencyFurnace typesQuenchingImpurity

The invention relates to a cold roll with a thick quench-hardened layer. Chemical constituents in materials of the cold roll include, by weight, 0.70-1.20% of C, 0.5-1.20% of Si, 0.60-1.00% of Mn, 2.50-4.00% of Cr, 0.20-1.00% of Mo, at most 0.30% of Ni, at most 0.015% of S, at most 0.015% of P and the balance Fe and unavoidable impurities. The thickness of the quench-hardened layer of the cold roll is increased, and secondary quenching for the cold roll during usage is avoided.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

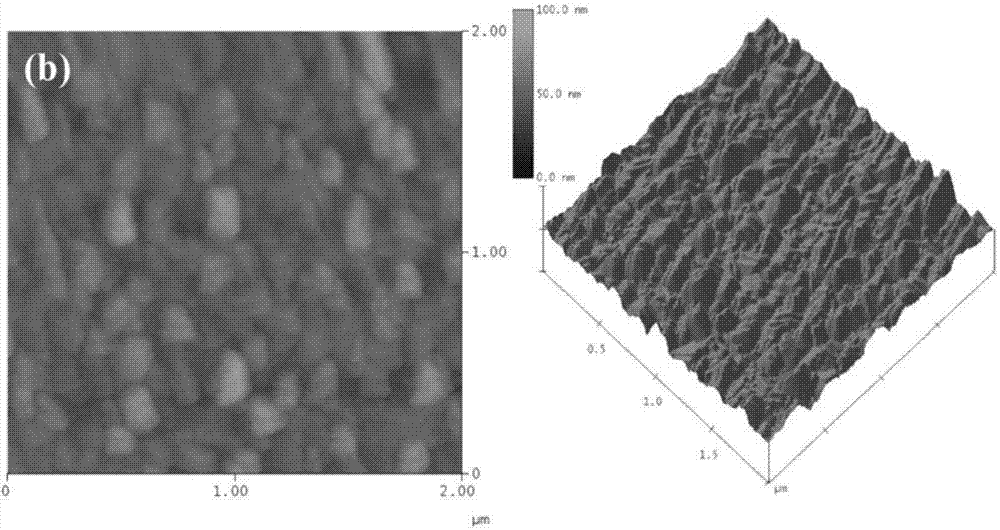

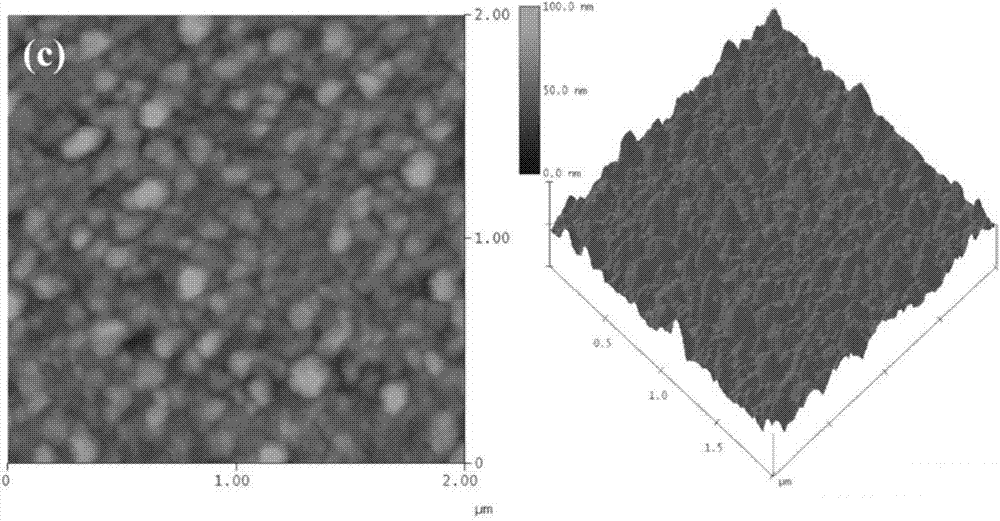

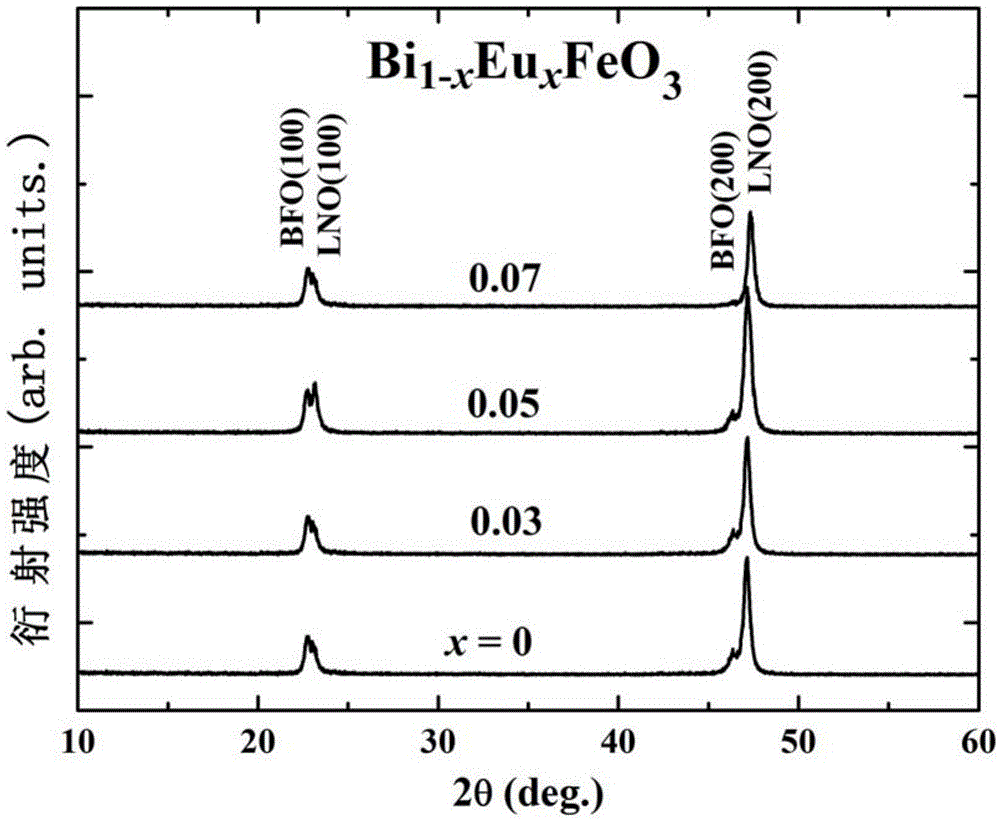

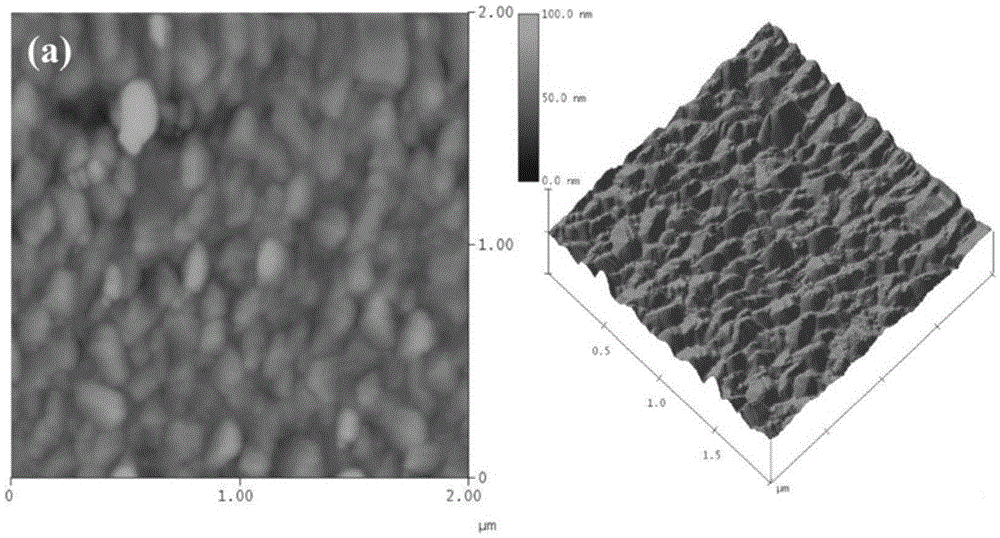

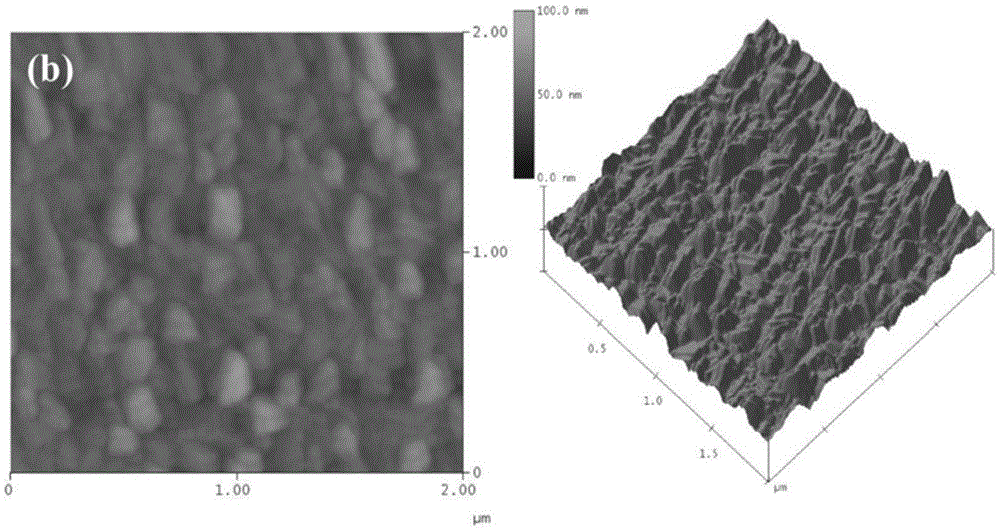

Europium doped bismuth ferrite film, preparation method and application thereof

InactiveCN103938156ASimple structureEasy to operateVacuum evaporation coatingSputtering coatingLanthanumEuropium

The invention discloses a europium doped bismuth ferrite film, which comprises a silicon substrate with lanthanum nickelate as the buffer layer and a target material with a composition formula of Bi1-xEuxFeO3 (with x being greater than or equal to 0 and smaller than or equal to 0.07). The target material is deposited on the substrate. The invention also discloses a preparation method of the europium doped bismuth ferrite film. The method consists of: cleaning the substrate, placing the target material and the substrate in a film coating chamber, adjusting the pressure to less than 5*10<-4>Pa, raising the temperature of the substrate to 700DEG C at a speed of 10DEG C per minute; adjusting the sputtering pressure to 10Pa, maintaining the state for 10min under 700DEG C and an oxygen pressure of 10Pa, making adjustment to invert the substrate and rotate the target material in forward direction, keeping a 6cm distance between the substrate and the target material, employing a pulse laser to conduct film deposition for 60min and performing heat preservation for 30min, then conducting cooling at a speed of 20DEG C per minute to 200DEG C, and taking out the product, thus obtaining the europium doped bismuth ferrite film. The preparation method provided by the invention has the advantages of easily controllable reaction process and easily available raw materials. The europium doped bismuth ferrite film has significantly improved crystallization properties and electric leakage properties, and a smaller optical band gap, thus improving the photovoltaic properties of BiFeO3 films. The europium doped bismuth ferrite film has wide application prospects.

Owner:EAST CHINA NORMAL UNIV

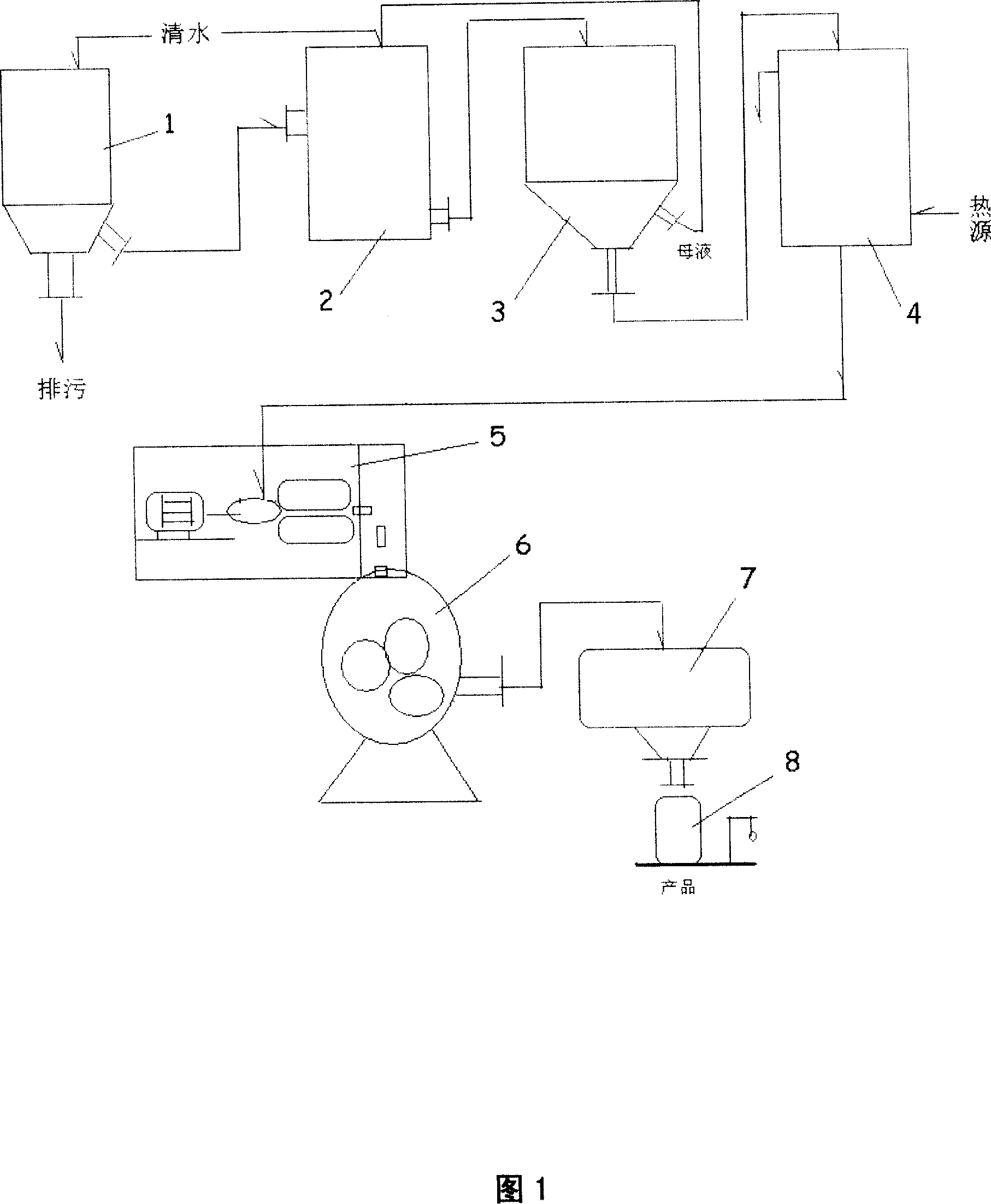

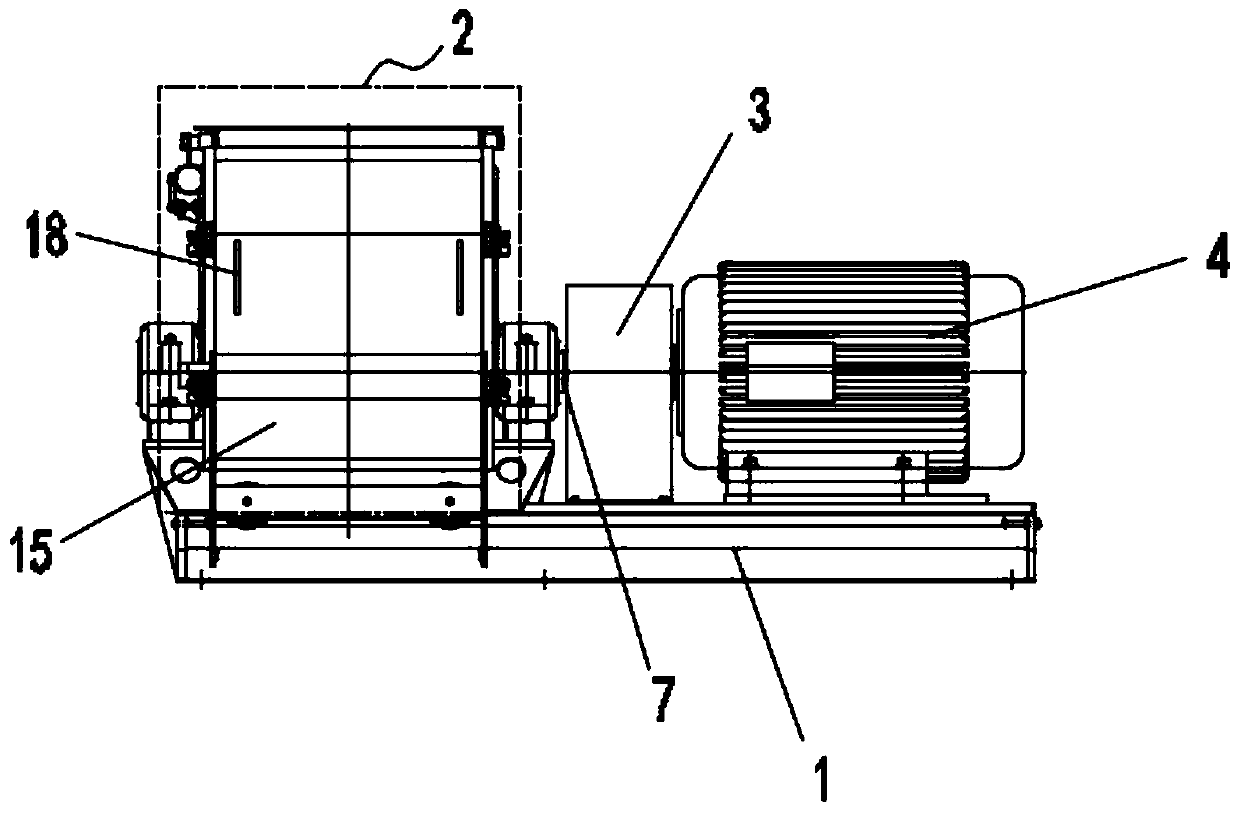

Wet production processs and apparatus of granular ferrous sulfate monohydrate

The present invention relates to production process and apparatus of granular ferrous sulfate monohydrate. The technological process includes the following steps: water washing and filtering ferric sulfite heptahydrate to purify, dissolving via heating, re-crystallizing, centrifugal drying to obtain ferric sulfite monohydrate powder with Fe content of 30-32 wt%, and returning the centrifugal mother liquid to the dissolving reactor; tabletting the ferric sulfite monohydrate powder, crushing, 2-60 mesh sieving in a vibrating sieve and packing.

Owner:梁永洪 +1

Manufacturing method for high manganese steel seamless pipe

The invention relates to a manufacturing method for a seamless pipe, and in particular to a manufacturing method for a high manganese steel seamless pipe with high strength and corrosion resistance. The manufacturing method for the high manganese steel seamless pipe comprises the following steps that a high manganese steel ingot comprising, by weight percentage (%), 0.08-0.60% of C, 0.10-3.60% of Si, 15.00-28.00% of Mn, 0.02-4.50% of Al, no more than 0.045% of P, no more than 0.045% of S, 0.01-0.30% of Nb, 0.001-0.040% of N, 0.01-0.20% of Ti, 0.01-0.20% of V, and the balance Fe and inevitable impurities is kept warm for 6-8 hours at the temperature of 1150-1250 DEG C, the steel ingot is hot-forged into a cylindrical blank at the temperature of 850-1150 DEG C, then the cylindrical blank is covered with a heat preservation cover quickly for slow cooling, and the cylindrical blank is air-cooled to the room temperature 48 hours later by hoisting the cover away.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

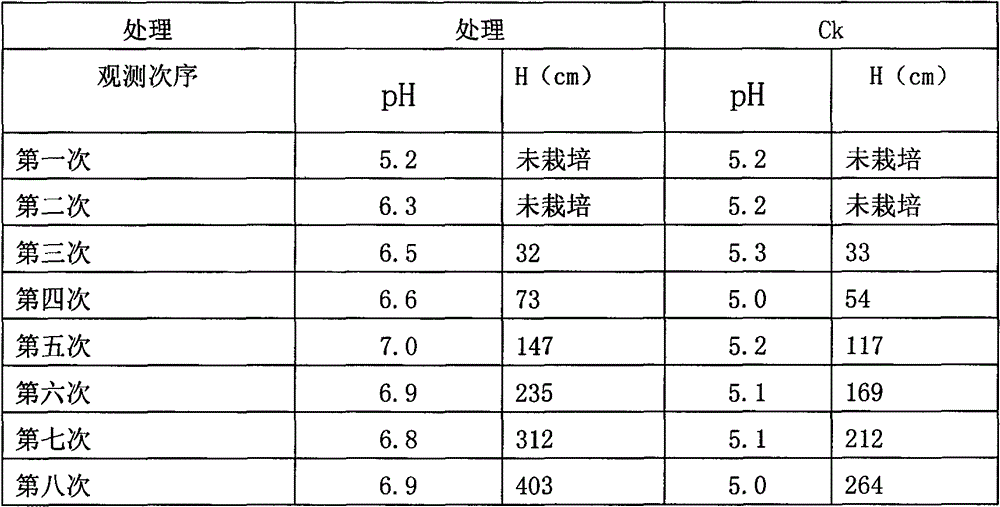

Soil conditioner using biomass power plant ash as main raw material, its preparation and application method

ActiveCN102424639BLarge specific surface areaSimple structureFertilizer mixturesSoil scienceEnvironmental engineering

The invention relates to a soil conditioner using biomass power plant ash as a raw material, comprising 80-94 wt% of biomass power plant ash, 5-10 wt% of saw powder, and 1-10 wt% of binding agent. The preparation method comprises the following steps: (1) mixing the raw materials in proportion, adding 0.15-0.30 times of water, and uniformly stirring; (2) carrying out granulation; (3) drying after granulation until the water content being 8-10 wt% at a temperature of 70-150 DEG C; and (4) sieving, weighing and bagging for subsequent use. The application method is characterized by using 50-150 kg of the soil conditioner in per 667 m<2> acid soil. According to the invention, the acid-base balance of the soil is greatly improved, the medium trace elements taken away from the soil in harvesting biomass are supplemented, the reasonable circulation of nutritive components is realized, the growth of plants is promoted; simultaneously the sustained release of mineral elements is achieved, and the utilization rate of fertilizers is greatly increased.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Preparation method of instant Maojian tea capable of building bodies

The invention relates to a method for preparing instant Maojian tea capable of building bodies from black Maojian tea as a raw material, belonging to the technical field of health beverages, and solving the problems of large granules, poor instant solubility, low nutritional value and poor mouth feel of existing Maojian tea capable of building bodies. The method comprises the concrete steps of adding water for soaking the black Maojian tea raw material; adding tannase, cellulase and pectinase for enzymatically hydrolyzing; adding beta-cyclodextrine and sodium hydrogen sulfite for well extracting effective ingredients from the raw materials; removing impurities; concentrating; drying; packaging. The method is simple in process. The instant Maojian tea prepared by adopting the method is high in effective ingredient content, moderate in tea granule size, good in porosity, convenient to dissolve in water, fresh and bright in tea soup color, rich in fragrance, and fragrant and slightly sweet in mouth feel.

Owner:山西林业职业技术学院

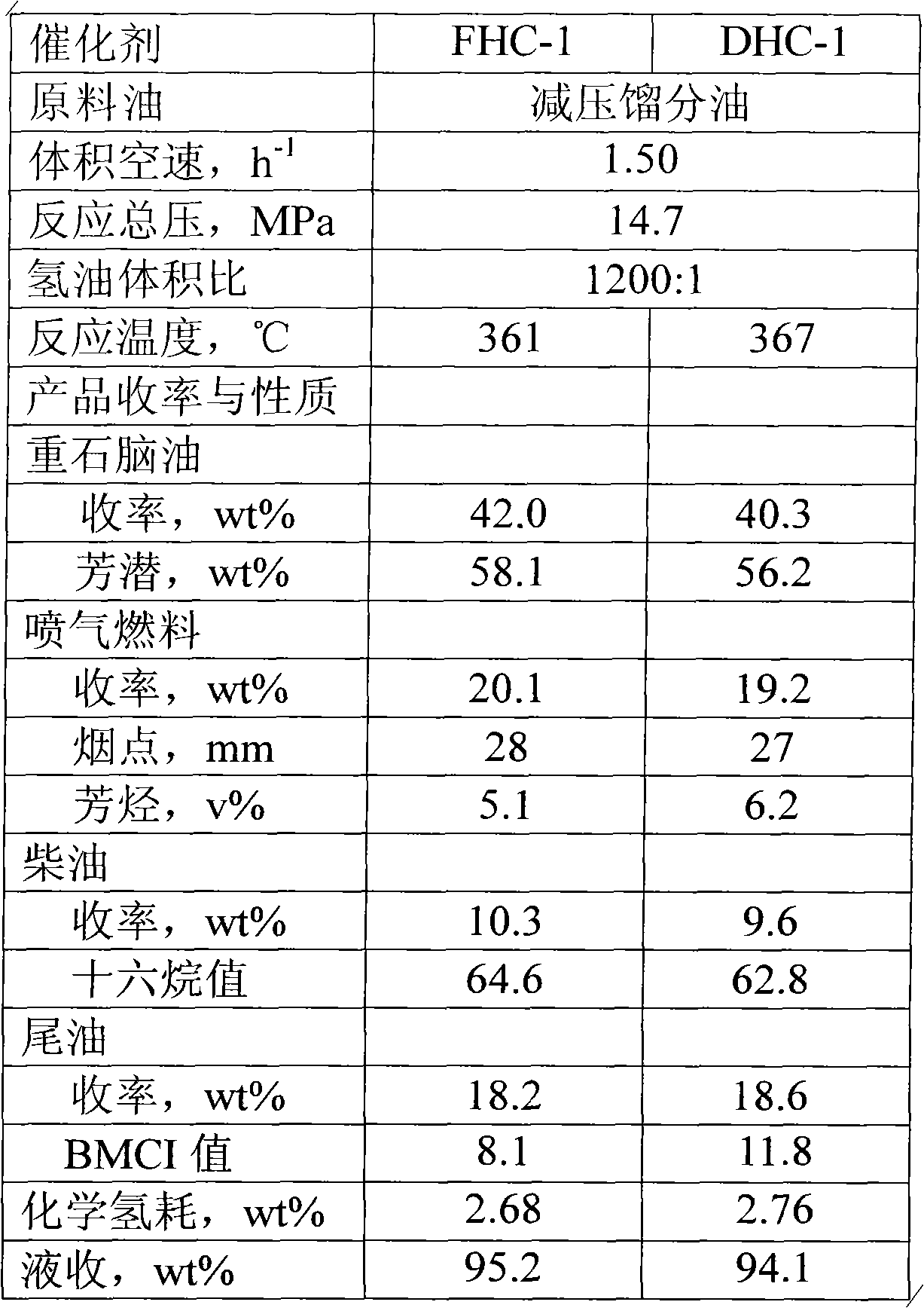

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN102049307AHigh crystallinityPreserve integrityCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The carrier consists of a small crystal particle Y-shaped molecular sieve and alumina, wherein the small crystal particle Y-shaped molecular sieve has high crystallinity, high ratio of silicate to aluminium, continuous and stable framework structure and smooth pores. A hydrocracking catalyst prepared from the carrier has the characteristics of high catalytic activity, high heavy naphtha selectivity, high potential aromatic hydrocarbon content, low bureau of mines correlation index (BMCI) value of hydrocracking tail oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of biapenem bulk drug

ActiveCN111875622AHigh purityThe status of impurities is clearAntibacterial agentsOrganic chemistryActivated carbonBiapenem

The invention provides a biapenem bulk drug preparation method, which comprises: 1) dissolving a biapenem crude product in water at a certain dissolving temperature T1 to prepare a biapenem crude product aqueous solution; (2) controlling the temperature of the biapenem crude product aqueous solution obtained in the step (1) to be T1 or T2, adding activated carbon with stirring for decolorization,filtering the liquid, and cooling the filtrate to T3 for later use; 3) dropwise adding the filtrate obtained in the step 2) into a mixed solvent of acetone and ethanol, which is cooled to T4 in advance, and crystallizing the filtrate; 4) growing crystal; and 5) separating, washing and drying the crystals separated out in the step 4) to obtain the biapenem bulk drug.

Owner:SHENZHEN HAIBIN PHARMA +2

Preparation and matching improvement method of saline-alkali soil conditioner

InactiveCN109971489ALarge specific surface areaImprove physical and chemical propertiesOther chemical processesOrganic fertilisersAlkali soilMoisture

The invention discloses a preparation and matching improvement method of a saline-alkali soil conditioner, which comprises the following steps of: S1, weighing raw materials in parts by mass: 200-320parts of residue of furfural, 110-120 parts of decomposed organic fertilizer, 50-65 parts of organic material, 70-80 parts of fly ash of a biomass power plant, 15-20 parts of inorganic fertilizer, 25-40 parts of amino acid and 5-10 parts of polyacrylamide; and S2, mixing the raw materials: placing the fly ash of the thermal power plant using biomass as a raw material into a vessel as a main material, adding the residue of furfural, the decomposed organic fertilizer, the organic material, the amino acid and the polyacrylamide, and then uniformly stirring. By means of the method, soil structureis effectively improved, mineral elements are slowly released, and utilization of the fertilizer is greatly improved; since a certain amount of the inorganic fertilizer is added, the soil moisture iskept to a certain extent, the soil aggregate structure is improved, the fertilizer efficiency is improved further; and moreover, a certain amount of nutrient substances can be provided for crops, so that the crop yield is increased, the economic benefit of farmland is improved, and the income of farmers is increased.

Owner:中国农业科学院西部农业研究中心

Preparation method of levofloxacin hydrochloride tablet

PendingCN112675141ANo significant effect on production processProduction Process ImpactAntibacterial agentsOrganic active ingredientsCarboxymethyl starchLevofloxacin

The invention discloses a preparation method of a levofloxacin hydrochloride tablet. The levofloxacin hydrochloride tablet is composed of levofloxacin hydrochloride, pregelatinized starch (viscosity is 5-20 cps), carboxymethyl starch sodium, povidone K30, stearic acid and talcum powder. The preparation method comprises the following steps of (1) burdening; (2) wet granulation; (3) drying; (4) granulating; (5) total mixing; (6) tabletting; and (7) coating. The levofloxacin hydrochloride tablet and the preparation method thereof have the advantages that the tablet forming effect is good, the prepared levofloxacin hydrochloride tablet has very high finished product content, it is ensured that the drug effect is brought into full play, the accuracy is good when the levofloxacin hydrochloride tablet is used for microbial limit inspection, and therefore good guarantee is provided for follow-up research and application of the levofloxacin hydrochloride tablet and preparation optimization. Therefore, the method is suitable for large-scale popularization and application.

Owner:DIAO GRP CHENGDU PHARMA

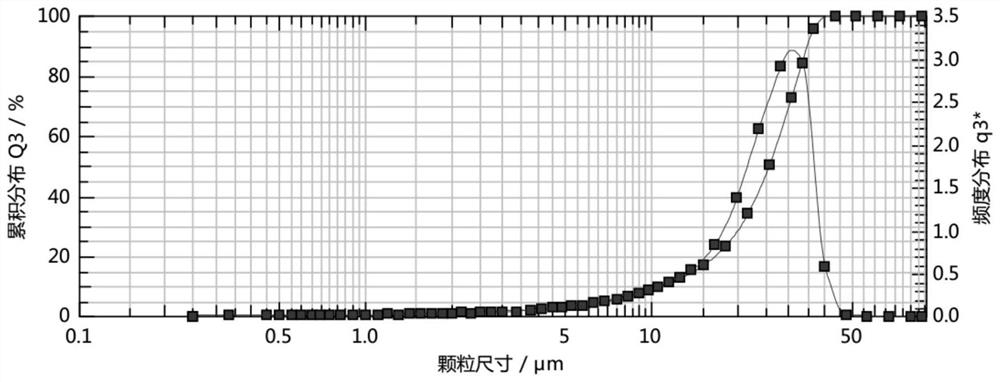

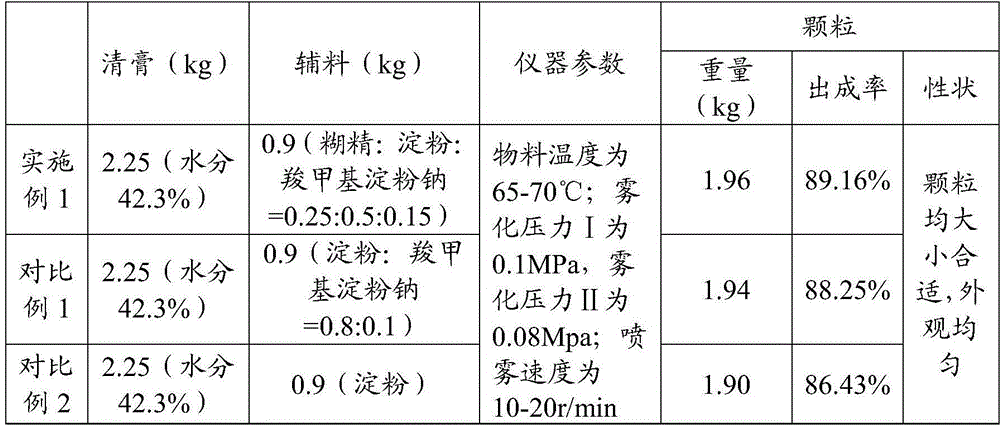

Preparation method of traditional Chinese medicine extract tablet

InactiveCN103976962AModerate grainParticles are of suitable sizePill deliveryMacromolecular non-active ingredientsMedicineTraditional medicine

A traditional Chinese medicine extract tablet comprises an extract of traditional Chinese medicine extract and an excipient; wherein the weight ratio of the extract to the excipient is (1.5-4):1, and the excipient is composed of dextrin, starch, and a disintegrating agent. The preparation method of the traditional Chinese medicine extract table comprises the following steps: extracting traditional Chinese herbals, drying the extract to obtain a dried extract, selecting an excipient comprising dextrin, starch, and a disintegrating agent, mixing the extract and the excipient according to a weight ratio of (1.5-4):1, carrying out spray-granulating, and finally pressing the granules into tablets, wherein the water in the extract accounts for 30 to 60% of the total weight of the extract, the material temperature is 60 to 80 DEG C after the extract and excipient mixing process, in the spray-granulating process, the atomizing pressure I is 0.05 to 0.1 MPa, the atomizing pressure II is 0.05 to 1 MPa, and the spraying speed is 10 to 20 r / min. The traditional Chinese medicine extract tablet has the advantages of proper size, uniform appearance, and prominently-reduced disintegration time.

Owner:NANCHANG JISHUN PHARMA CO LTD

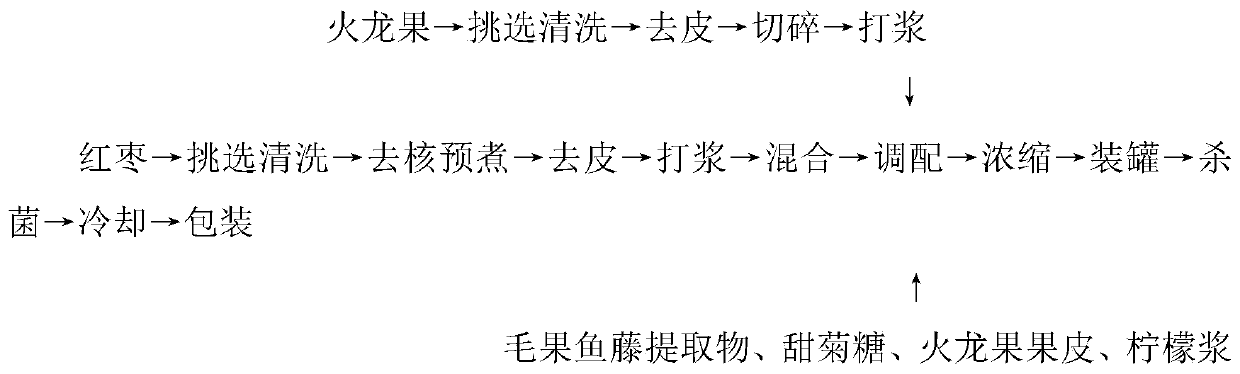

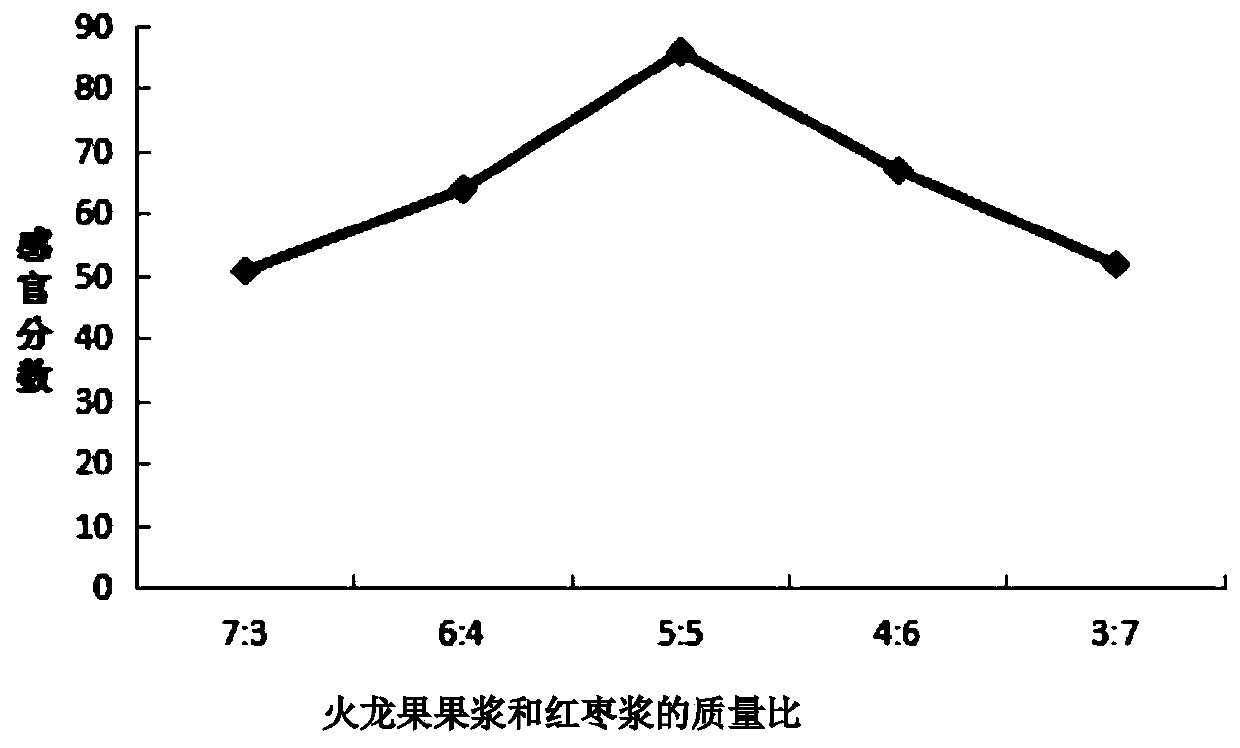

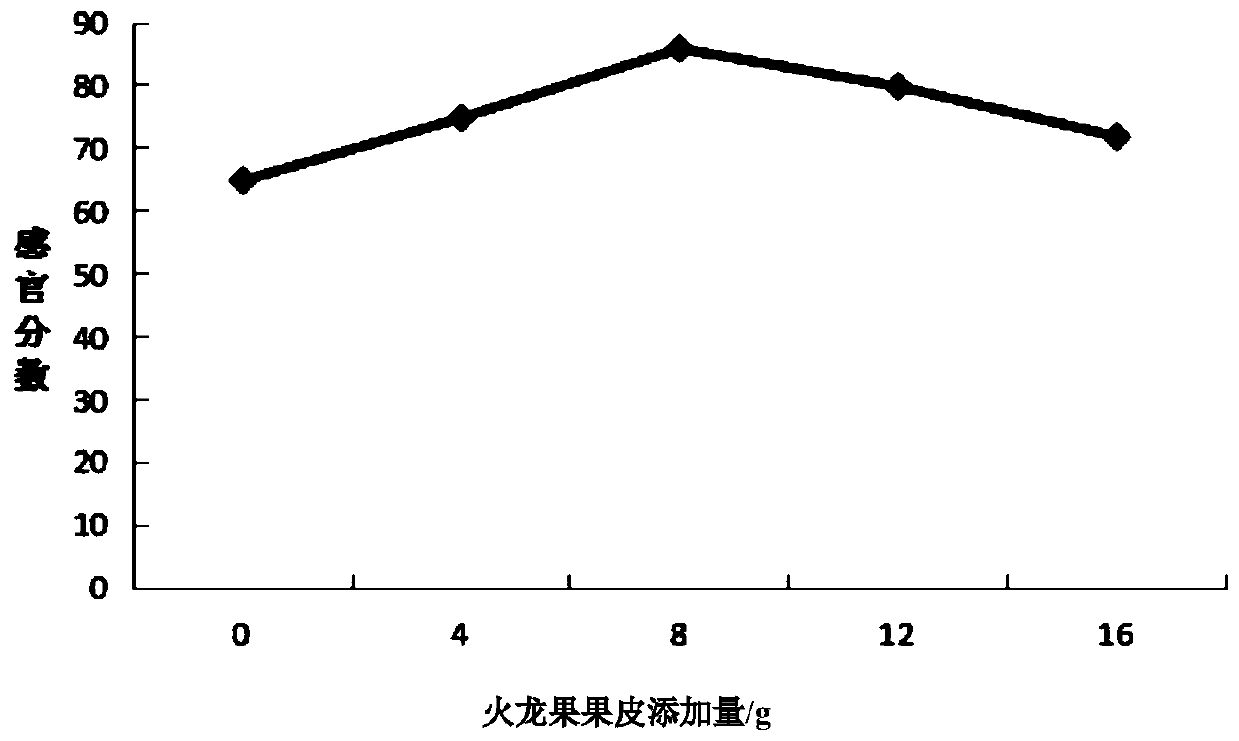

Pitaya jujube compound jam and preparation method thereof

InactiveCN110179080ABest formulaUniform and bright colorFood preservationNatural extract food ingredientsDerris eriocarpaZiziphus jujuba

The invention discloses a pitaya jujube compound jam and a preparation method thereof. Every 100g of mix pulp contains 0-16g of pitaya peel, 5-25g of derris eriocarpa extract, 0-1g of stevioside and 0-8g of lemon pulp. The mixed pulp is made up of pitaya pulp and jujube pulp in mass ratio of (3-7): (3-7). The preparation method comprises the following steps: S1: raw materials selection; S2: cleaning; S3: preparing pitaya pulp; S4: preparing jujube pulp; S5: processing ingredients; S6: mixing and concentrating; S7: filling and sterilization; S8: cooling and packaging and obtaining jam with bestquality by a single factor test under an orthogonal L9 (43) optimization test condition. The test results show that the pitaya jujube compound jam has the optimal mouthfeel and taste in case of 5: 5of mass ratio between the pitaya pulp and the jujube pulp (in 100g of mixed pulp), 12g of added pitaya peel, 15g + 0.5g of ratio between the derris eriocarpa extract and the stevioside and 6g of addedlemon.

Owner:BENGBU COLLEGE

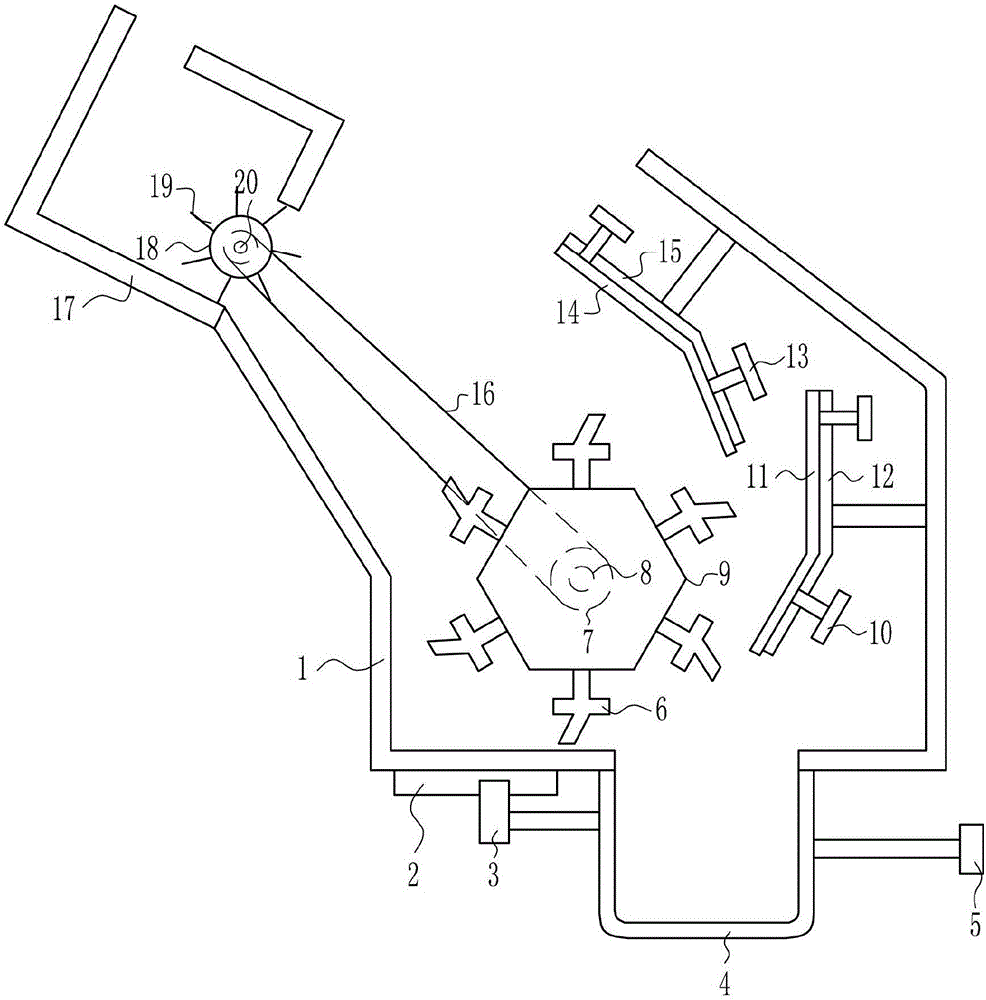

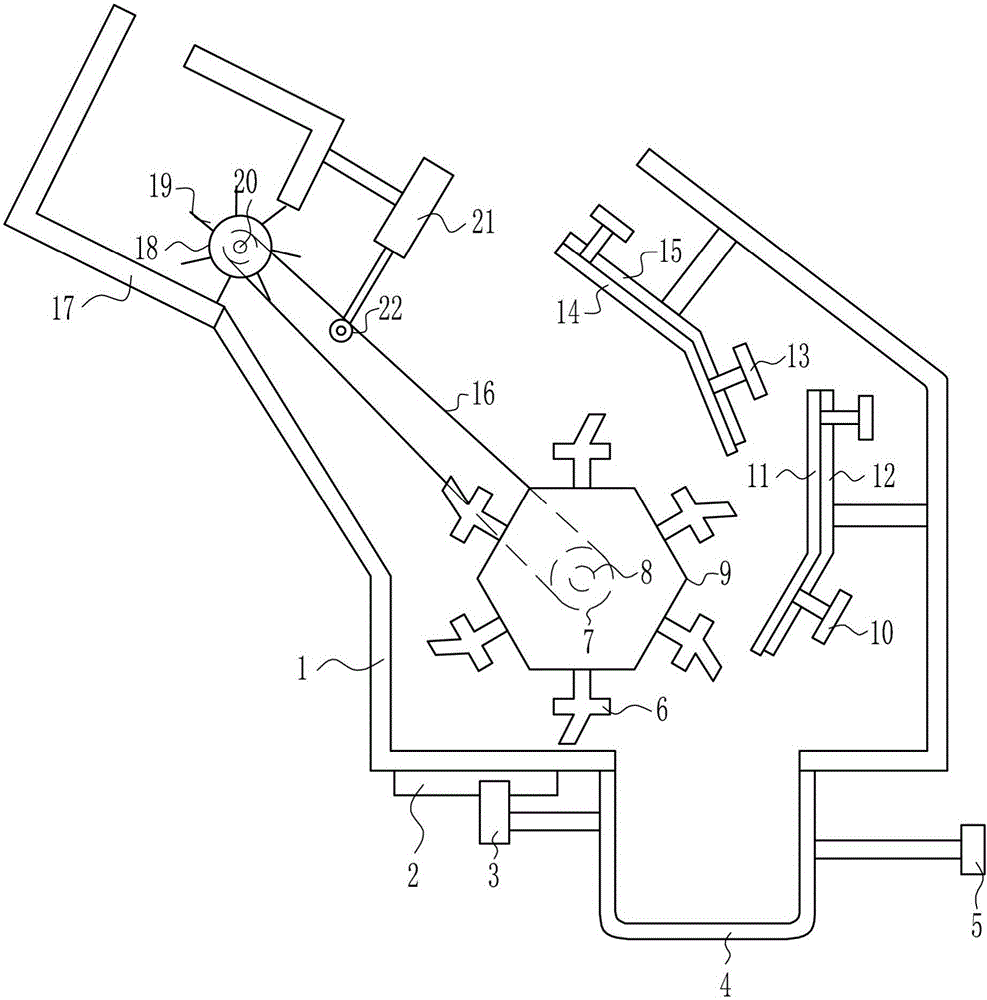

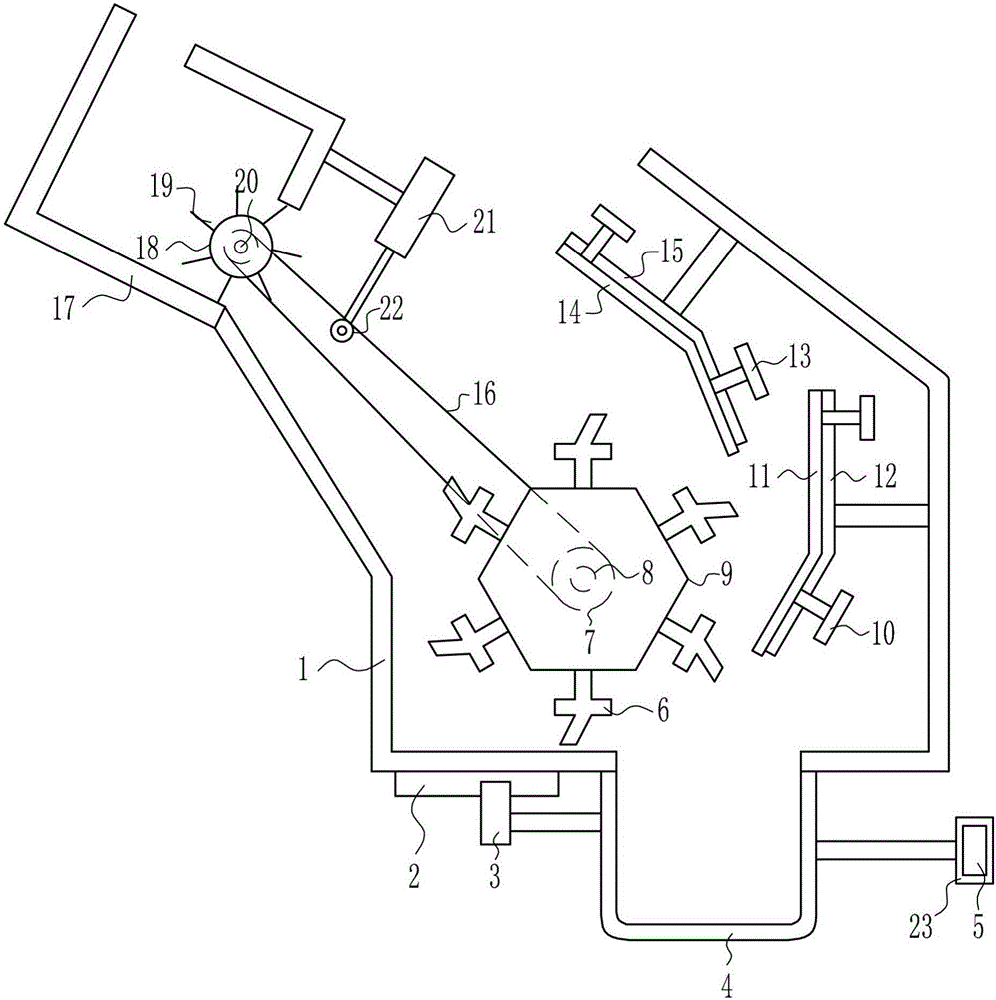

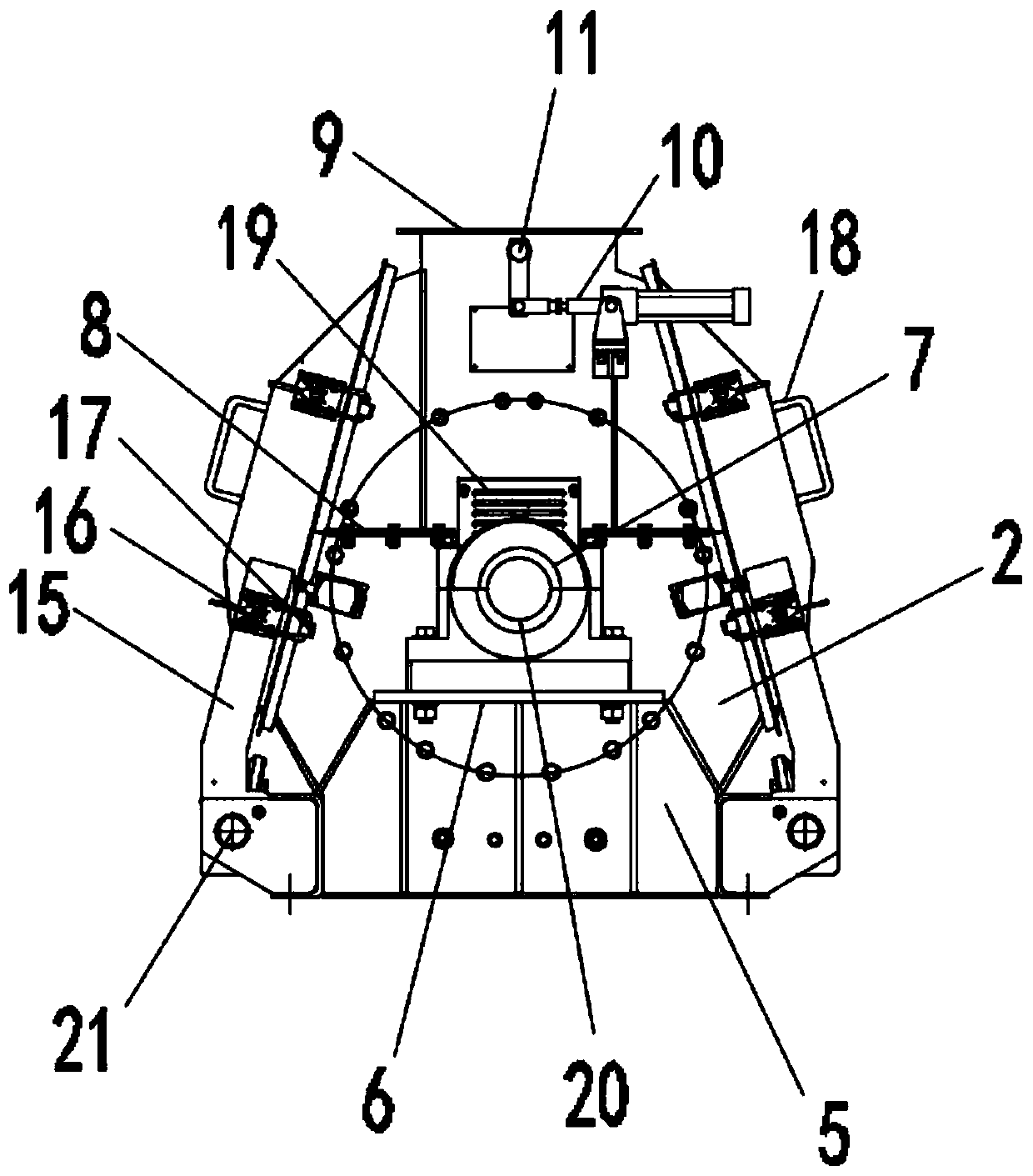

High-efficiency crushing device for feed for livestock farming

InactiveCN106179596ALess prone to cloggingNot prone to cloggingFeeding-stuffGrain treatmentsAdditive ingredientEngineering

The invention relates to a crushing device for feed for livestock farming, in particular to a high-efficiency crushing device for feed for livestock farming. In order to solve the technical problems, the invention provides the high-efficiency crushing device for feed for livestock farming, and the high-efficiency crushing device achieves the effects that feed blockage is not liable to occur, crushed particles are proper, and feed nutrition ingredient loss is less. The high-efficiency crushing device comprises a crushing box, a slide rail, a slide block, a collecting box, a handle, a third crushing plate, a first belt wheel, a reduction motor, a hexagonal rotary plate, a second bolt, a second crushing plate, a second mounting plate, a first bolt and the like; and the top end of the left side of the crushing box is connected to a placing box. The crushing device achieves the effects that feed blockage is not liable to occur, crushed particles are proper, and feed nutrition ingredient loss is less; and the crushing device is very is simple in structure, and is not liable to generate a feed blockage phenomenon.

Owner:王杭花

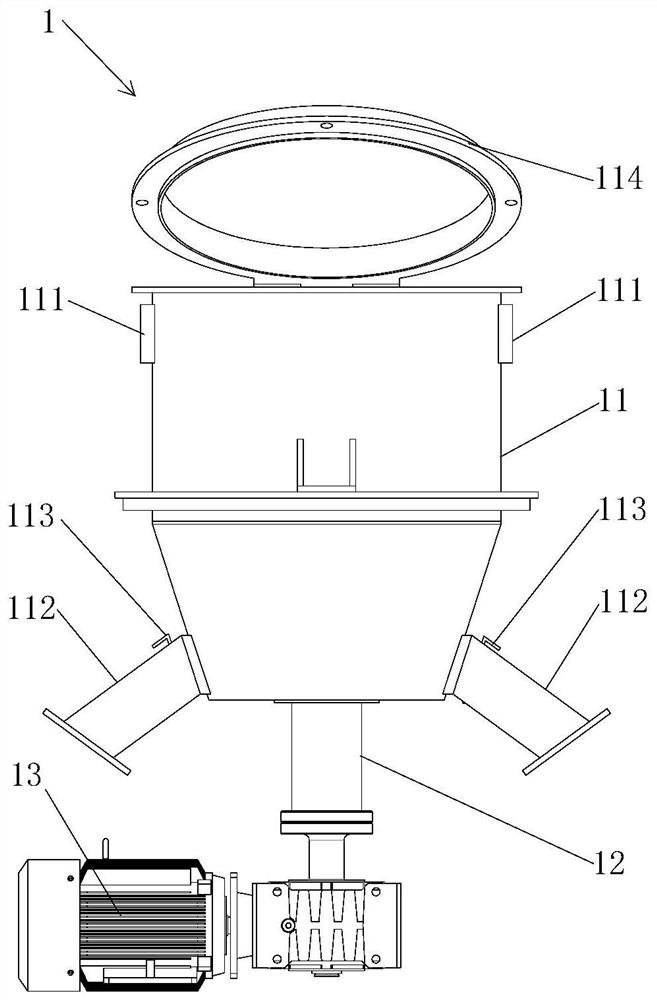

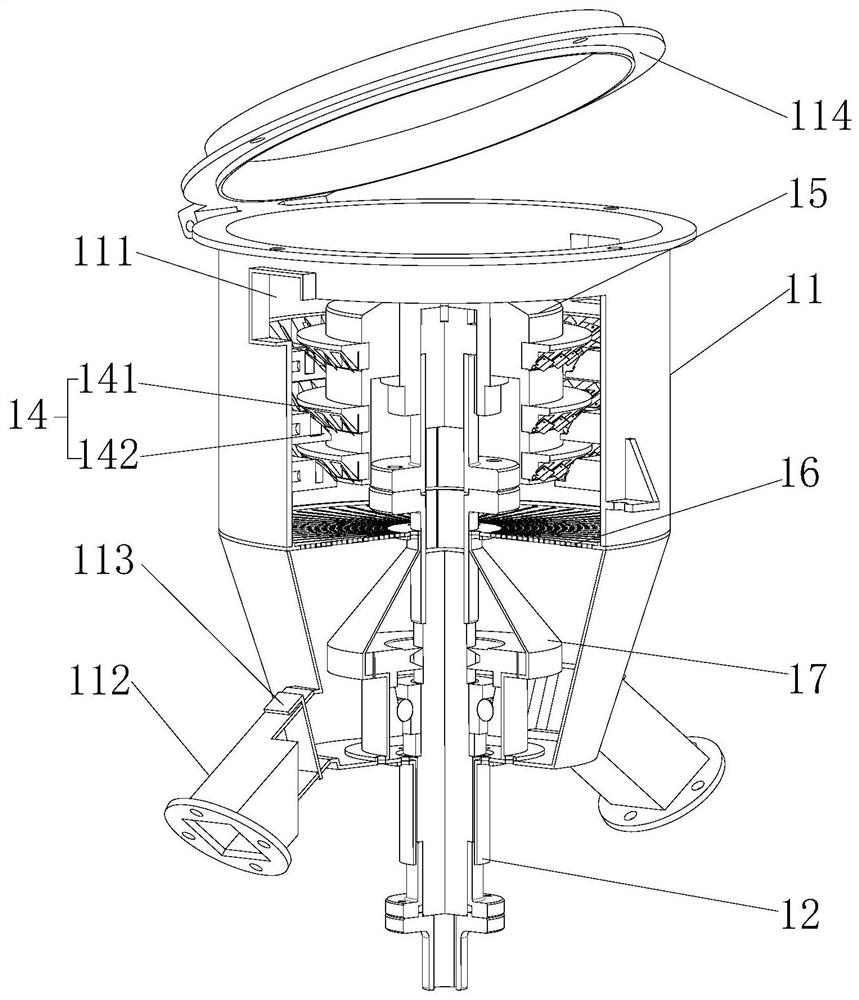

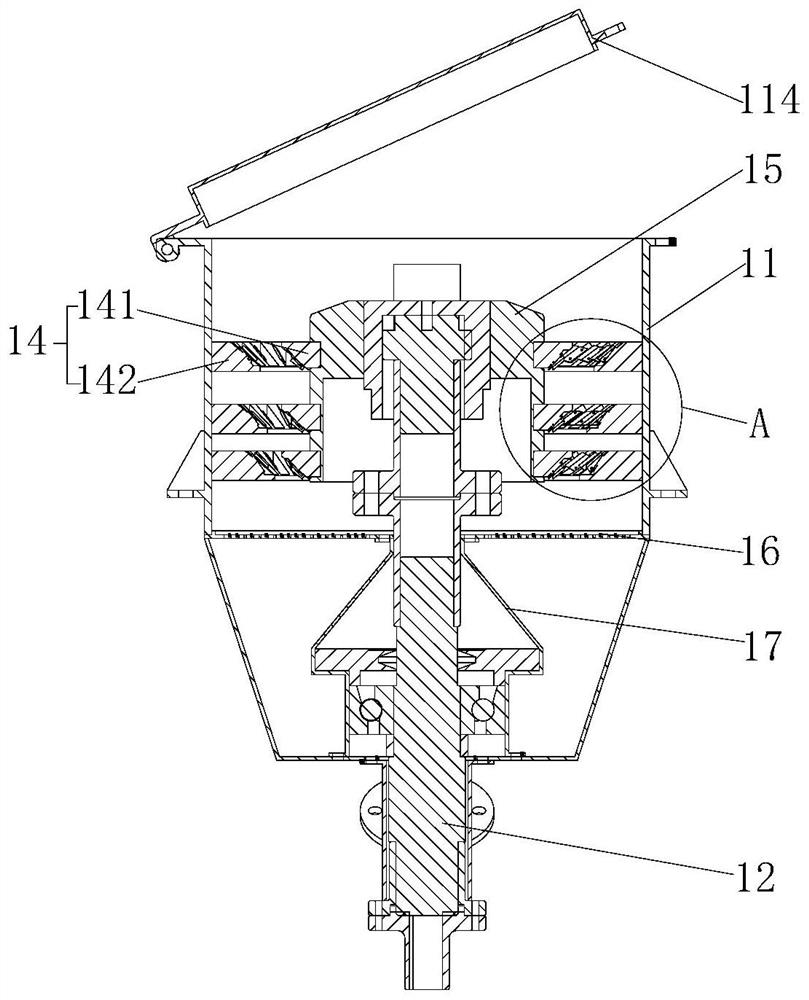

Stirring and crushing unit and 3D printing waste recovery device

InactiveCN112171964AEasy to mix wellMake sure to smashAdditive manufacturing apparatusPlastic recyclingWaste recoveryWaste material

The invention relates to the technical field of 3D printing, in particular to a stirring and crushing unit and a 3D printing waste recovery device. The stirring and crushing unit comprises a shell, arotating shaft and crushing assemblies. A feeding port and a discharging port are arranged on the shell. The rotating shaft is mounted in a vertical rotation manner. At least part of the rotating shaft extends into the shell. The number of the crushing assemblies is at least two. Each crushing assembly comprises a fixed cutter ring and a movable cutter ring which are used in cooperation. The fixedcutter ring is arranged on the inner wall of the shell. The movable cutter ring rotates along with the rotating shaft. The at least two crushing assemblies are arranged in an axially spaced manner. The working surfaces of one fixed cutter ring and the corresponding movable cutter ring are conical surfaces with a radial gap between; and the maximum radial gap and the minimum radial gap between thecutter rings of the at least two crushing assemblies sequentially narrow down downwards in the axial direction. The technical problem that in the prior art, particles obtained after waste is crushedare large in size, and subsequent processing is inconvenient to carry out is solved.

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

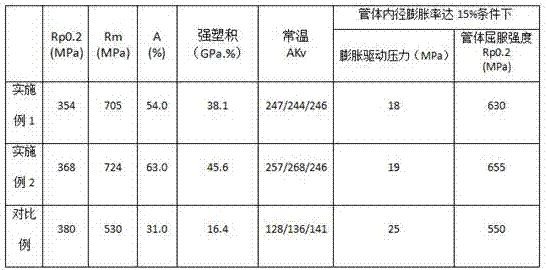

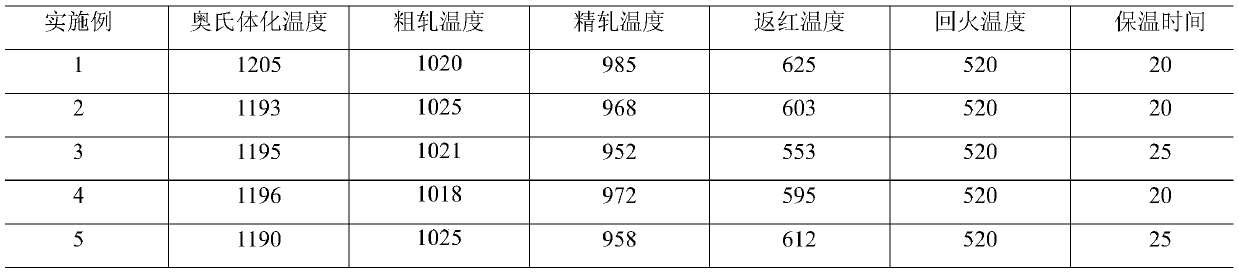

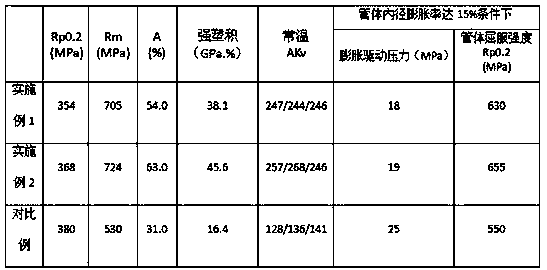

Ultralow-yield-ratio steel applied to single-rail turnout junction and production method of ultralow-yield-ratio steel

The invention discloses ultralow-yield-ratio steel applied to a single-rail turnout junction. The ultralow-yield-ratio steel comprises the following chemical elements in percentage by weight: 0.02% to0.16% of C, 0.15% to 0.50% of Si, 0.80% to 1.80% of Mn, 0.004% to 0.015% of P, smaller than or equal to 0.005% of S, 0.010% to 0.050% of Nb, 0.008% to 0.020% of Ti, 0.25% to 0.45% of Ni, 0.40% to 0.60% of Cr, 0.25% to 0.45% of Cu, 0.015% to 0.050% of Al and the balances Fe and inevitable impurities. According to the ultralow-yield-ratio steel disclosed by the invention, a structure consisting ofsoft-phase ferrite and hard-phase pearlite of which the crystal grains are moderate in size is obtained by utilizing a tempering process, and thus an ultralow-yield-ratio steel plate applied to the single-rail turnout junction is obtained.

Owner:NANJING IRON & STEEL CO LTD

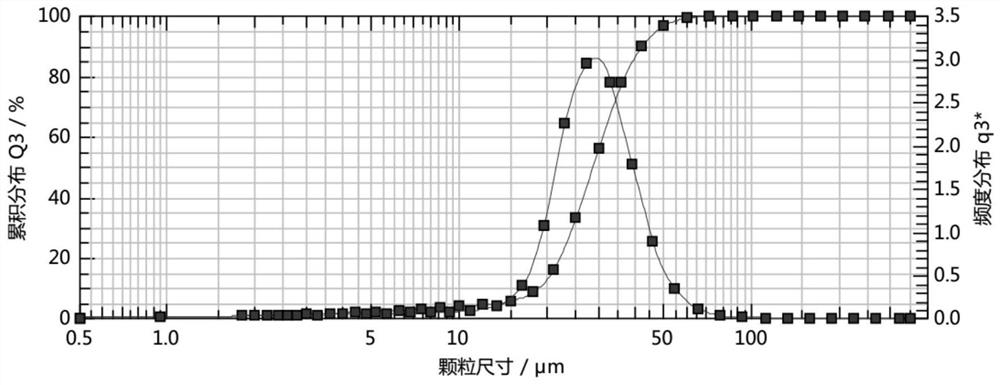

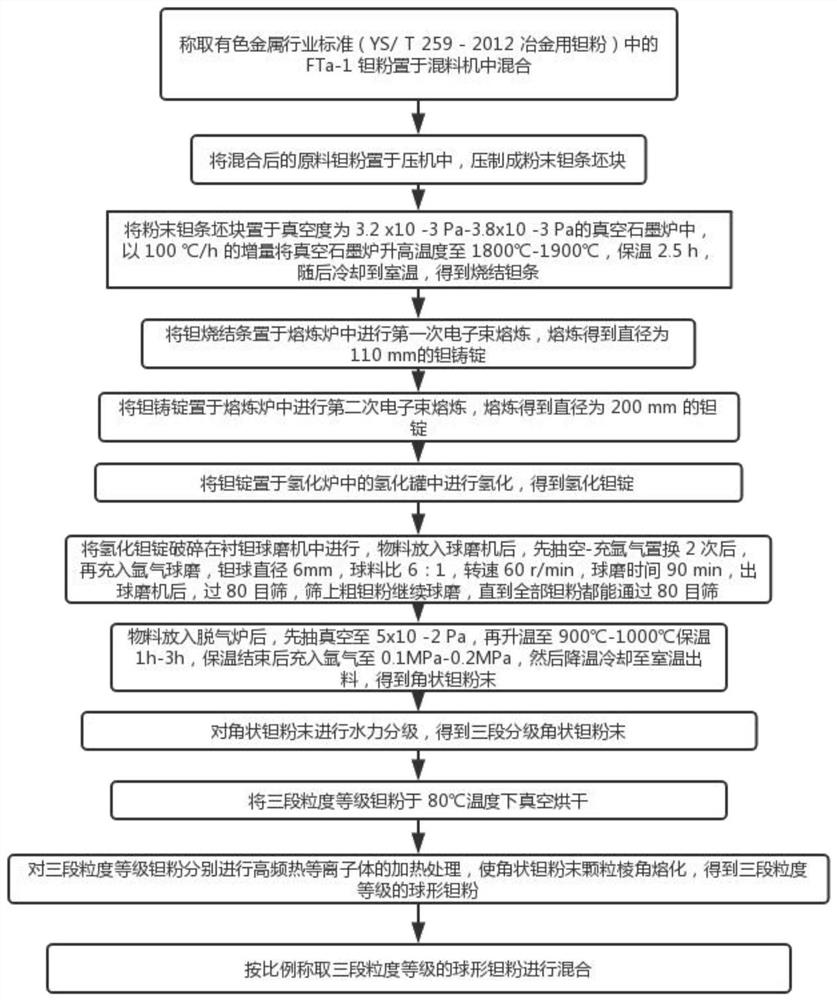

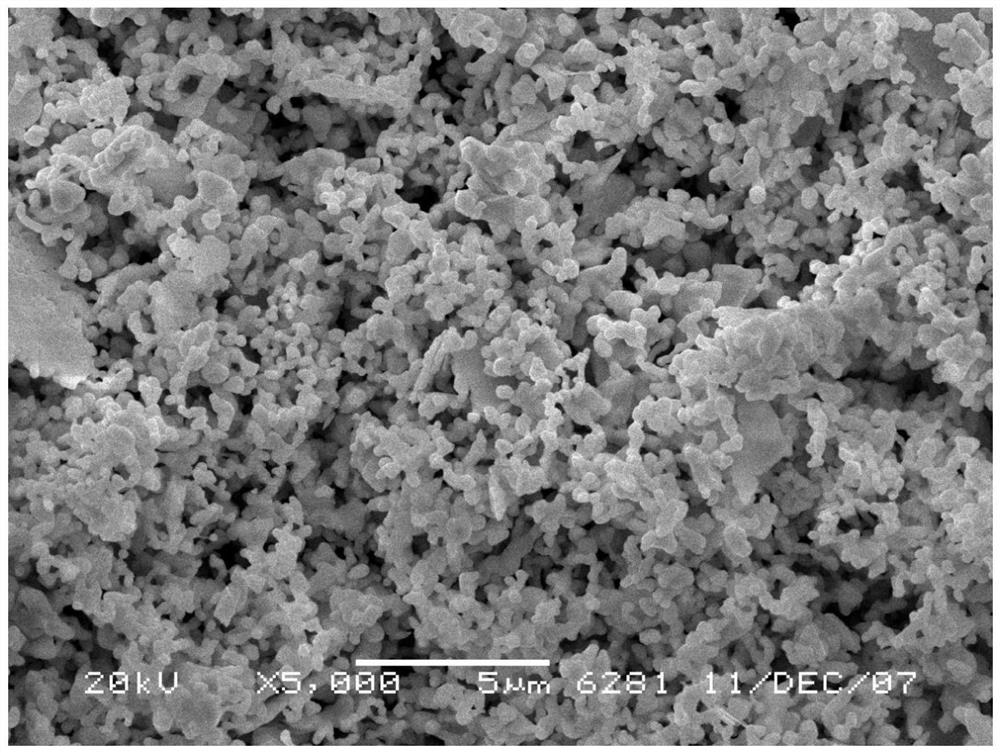

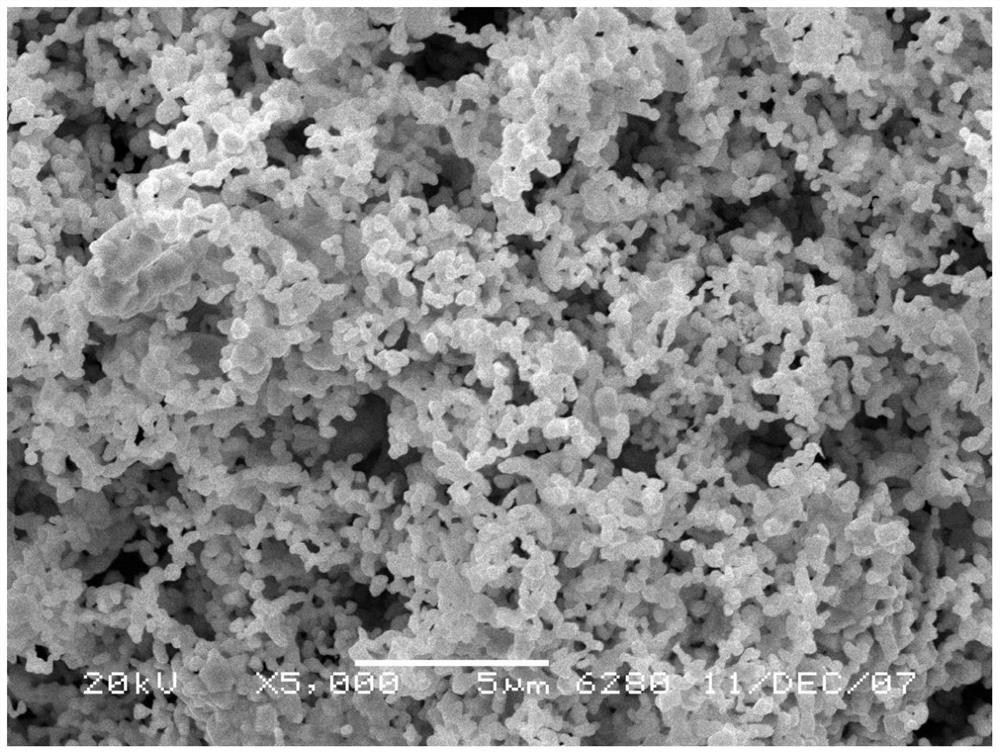

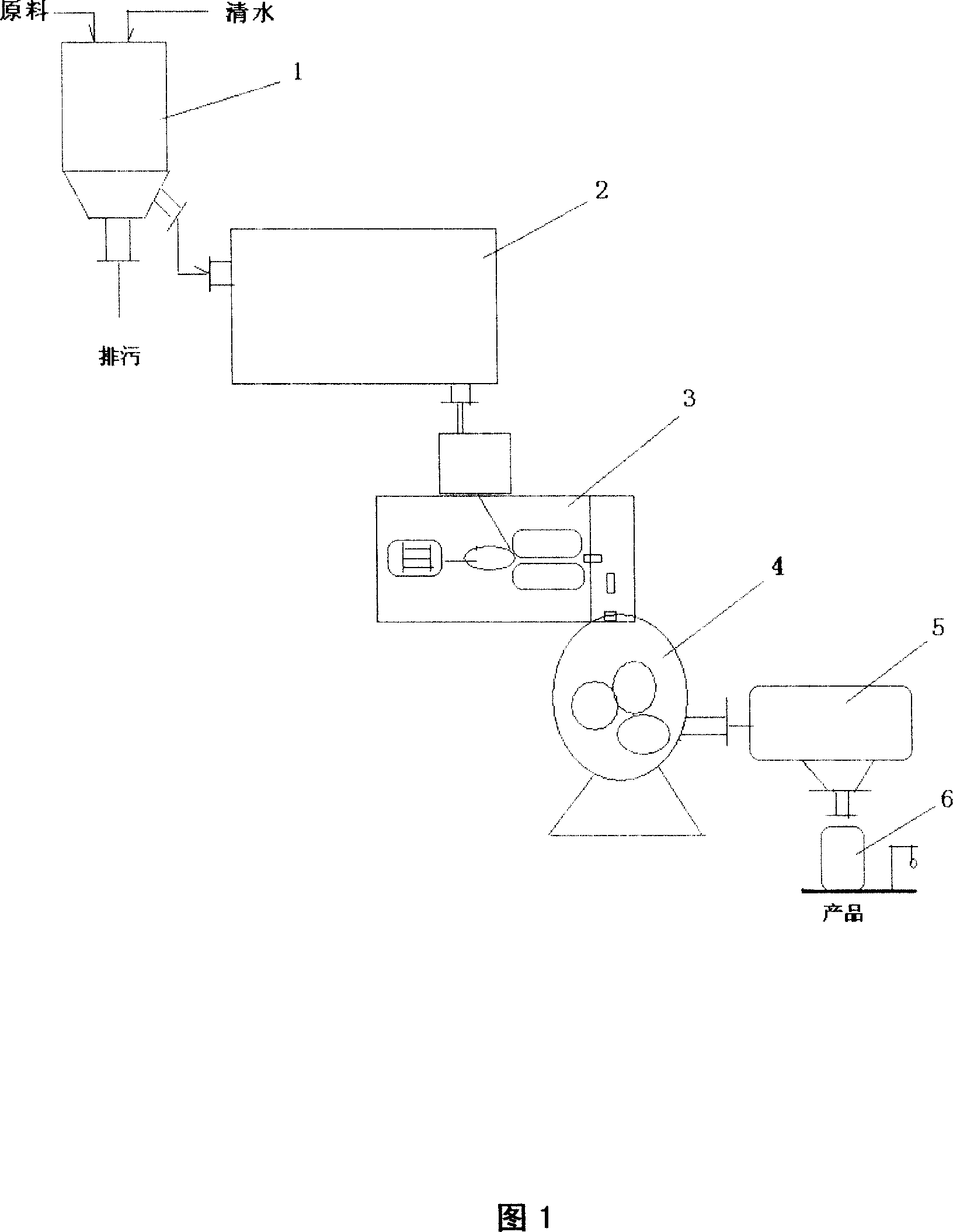

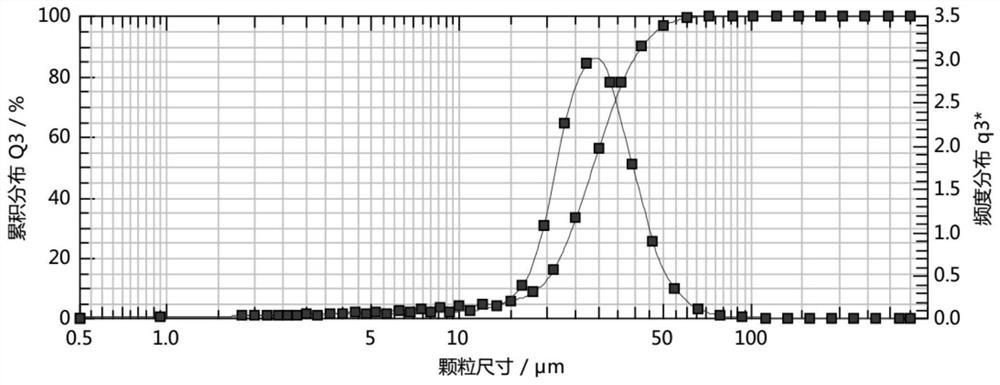

Spherical tantalum powder as well as preparation method and application thereof

PendingCN113560561AHigh purityShort processSolid electrolytic capacitorsIncreasing energy efficiencySecondary electronsElectron bunches

The invention discloses spherical tantalum powder and a preparation method and application thereof, and relates to the field of metal powder preparation. The preparation method comprises the steps of raw material weighing, briquette preparation, tantalum strip sintering, primary electron beam smelting, secondary electron beam smelting, hydrogenation, tantalum ingot smashing, dehydrogenation, hydraulic classification, drying, heating treatment and mixing, an oxygen content of the prepared spherical tantalum powder is smaller than or equal to 150 ppm, a carbon content is less than or equal to 20 ppm, an iron content is less than or equal to 10 ppm, and the electrical property is that a working voltage of a liquid tantalum capacitor is 75-150 V; a specific capacitance CV of an anode of the capacitor is 2000-4000 [mu] FV / g; and a leakage current is less than or equal to 4.5 * 10 <-4 > [mu] A / [mu] FV, and a breakdown voltage is greater than or equal to 350 V. The tantalum powder has proper particles and pore size distribution and impregnation characteristics, a conductive polymer can enter the anode more easily, more charges are led out, and the capacitance of the anode is higher. And meanwhile, in the anode forming process, an oxidation film grows more uniformly, the leakage current is smaller, and the breakdown voltage is higher.

Owner:炎陵龙翔钽铌新材料有限责任公司

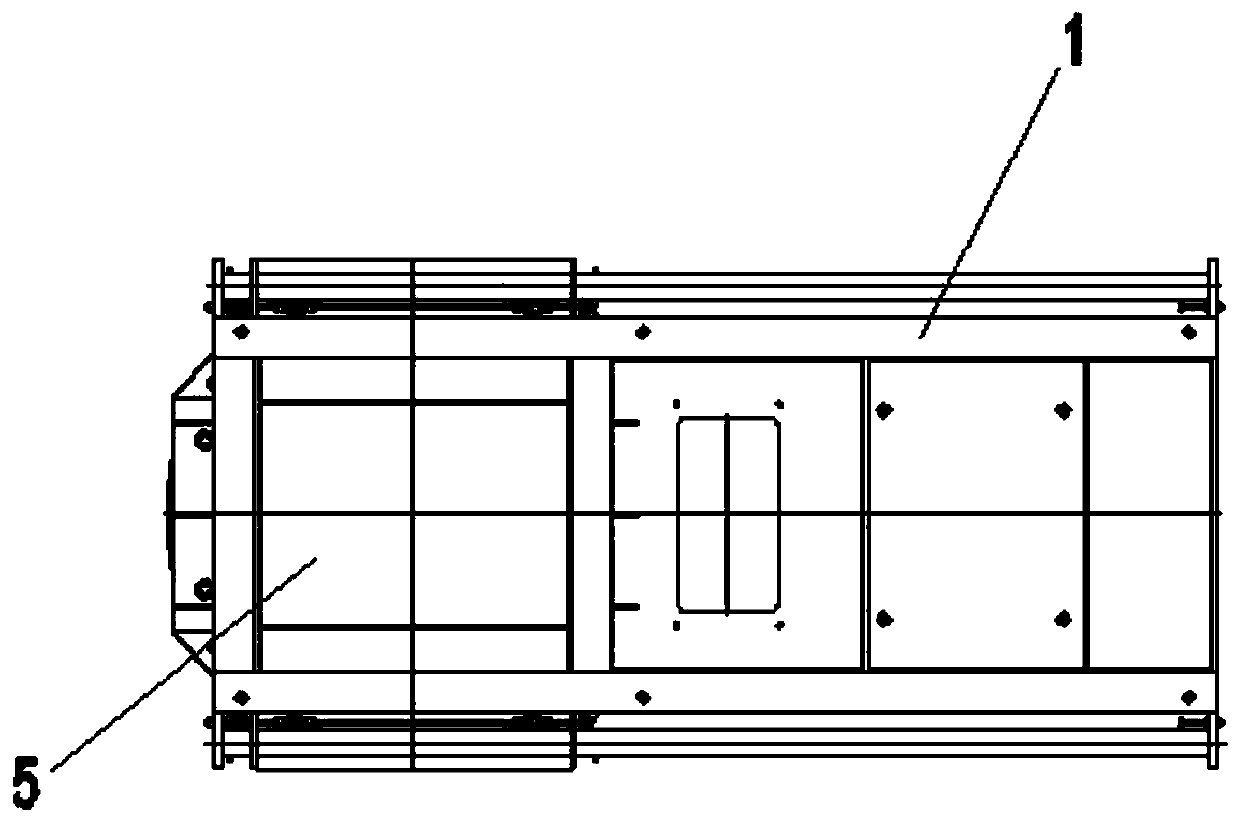

Particulate ferrous sulfate heptahydrate and its preparing method and device

InactiveCN101012070AOvercome the shortcomings of easy moisture absorption and cakingEasy to packIron sulfatesFerrous sulphate heptahydrateImpurity

The invention discloses a blue green or light blue particle-shaped ferrous sulphate heptahydrate and manufacturing method and equipment with diameter at 1-8mm, which comprises the following steps: washing ferrous sulphate heptahydrate in the cleaning pond to remove surface impurity; filtering; drying; obtaining pure ferrous sulphate heptahydrate; drying; punching to obtain the piece with thickness at 2-10mm; breaking; separating through vibrating sieve; collecting 2-60 order particle; packing; blending dried piece and ferrous sulphate heptahydrate to punch again.

Owner:梁永洪 +1

Method for extracting diamond abrasives from silicon carbide crystal grinding waste materials

ActiveCN102774831ASmall particlesModerate grainOther chemical processesChemical industryGranularityTube furnace

The invention discloses a method for extracting diamond abrasives from silicon carbide crystal grinding waste materials. The method comprises the following steps that silicon carbide crystal grinding waste materials are added into sulfuric acid solution with the concentration being 10 to 20 percent to be at least soaked for 24 hours, so the silicon carbide crystal grinding waste materials and the sulfuric acid solution take complete reaction and are then subjected to still standing and sedimentation; supernatant after the still standing sedimentation is poured out, and deionized water is used for diluting the precipitates after the still standing sedimentation for 3 to 5 times; the obtained mixture is placed into a baking oven to be subjected to baking treatment; and the obtained mixture is placed into a tubular furnace to be subjected to constant temperature treatment for 1 to 3 hours after being heated to the preset temperature in the air under the temperature condition being 520 to 750 DEG C, and the required diamond abrasives are obtained. The method for extracting diamond abrasives from silicon carbide crystal grinding waste materials provided by the invention can overcome the defects of energy source waste, too small diamond particle granularity, high enterprise production cost and the like in the prior art, and the advantages of energy source saving, proper diamond particle granularity and low enterprise production cost can be realized.

Owner:XINJIANG TANKEBLUE SEMICON

Metal anticorrosive paint and preparation method thereof

InactiveCN111019421AExcellent adhesionHigh glossAnti-corrosive paintsGrain treatmentsButyl methacrylateThermoplastic

The invention discloses a metal anticorrosive paint and a preparation method thereof. The metal anticorrosive paint is prepared from the following components in parts by mass: 10 to 15 parts of butylmethacrylate; 4-5 parts of cyclohexanone, 3-4 parts of titanium dioxide, 1-2 parts of an epoxy resin curing agent; 3 to 6 parts of propylene glycol phenyl ether; 10 to 15 parts of pentaerythritol; 8 to 15 parts of a pigment and filler; 5-6 parts of polyether silicone oil, 1-2 parts of polytetrafluoroethylene wax, 1-2 parts of a titanate coupling agent, 4-6 parts of a leveling agent, 1-2 parts of zinc phosphate, 15-25 parts of butyl acetate, 6-12 parts of graphite, 8-10 parts of hydroxypropyl methyl cellulose, 2-3 parts of xylene, 35-50 parts of a thermosetting high-salt resin and 15-25 parts of novolac epoxy resin and chlorinated polyether resin. The thermosetting high-salt resin has the characteristics of curing crosslinking and infusibility of a coating after crosslinking, an infusible hard-texture coating can be formed after a curing agent with a crosslinking reaction is added and heated, and the coating prepared from the thermosetting high-salt resin cannot be softened like a conventional thermoplastic coating under the condition of high temperature, and is good in stability.

Owner:苏州拓洁环保工程有限公司

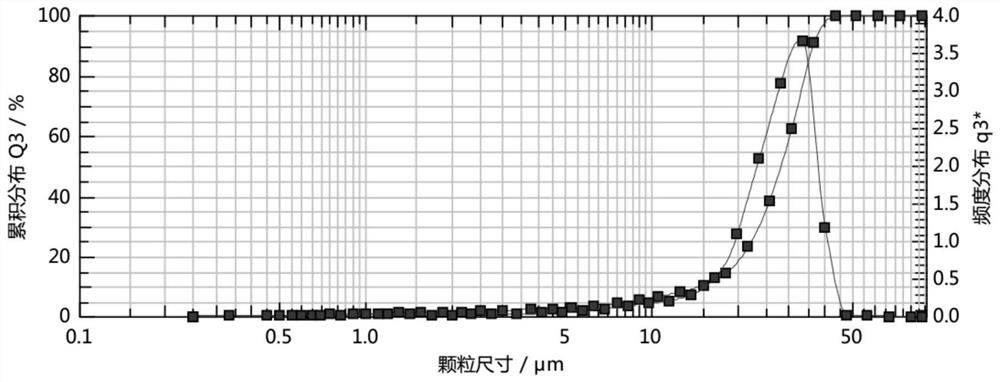

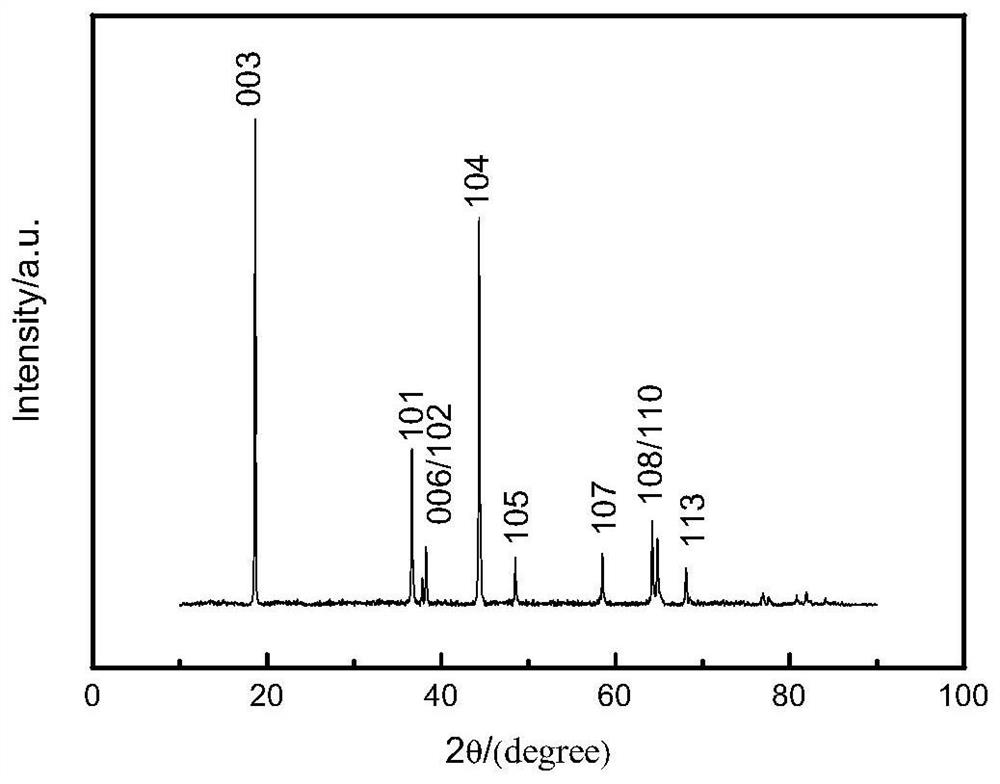

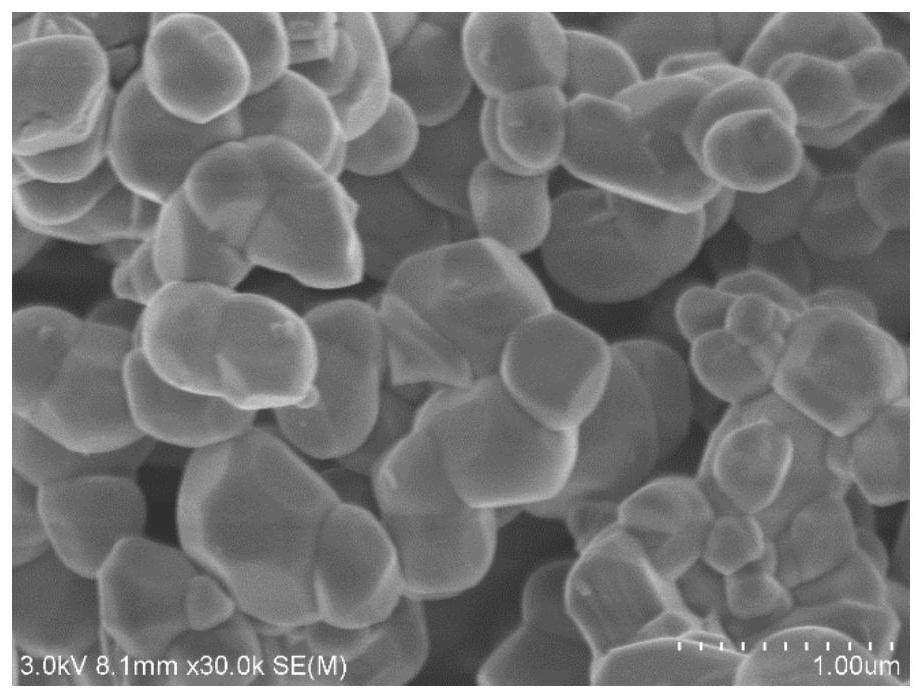

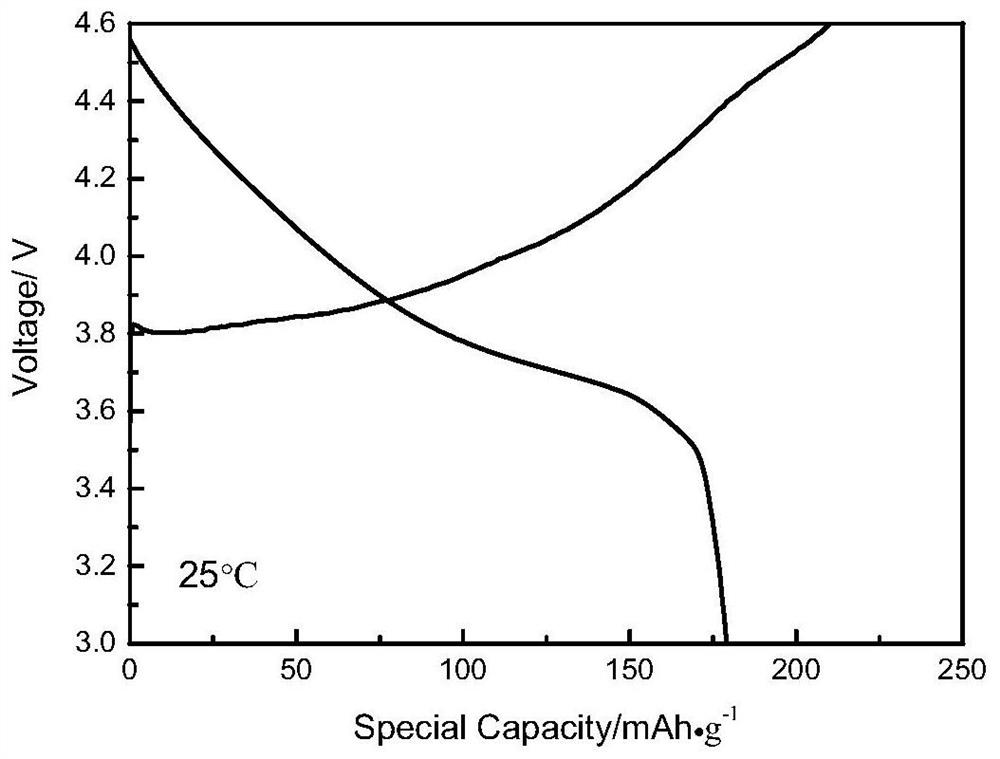

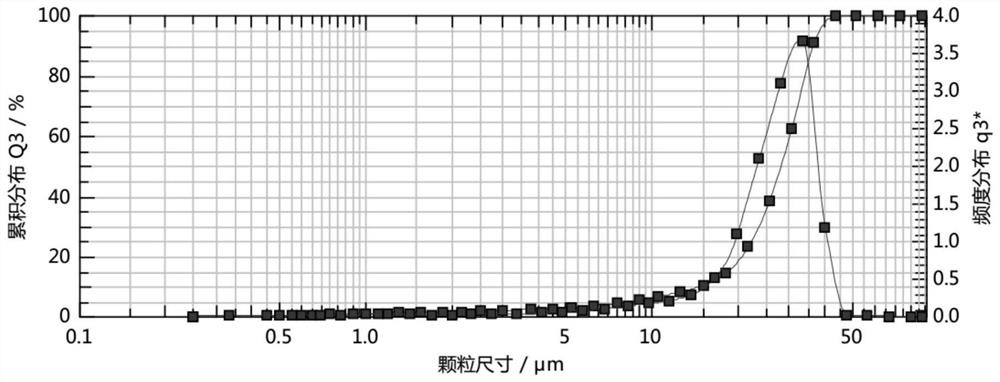

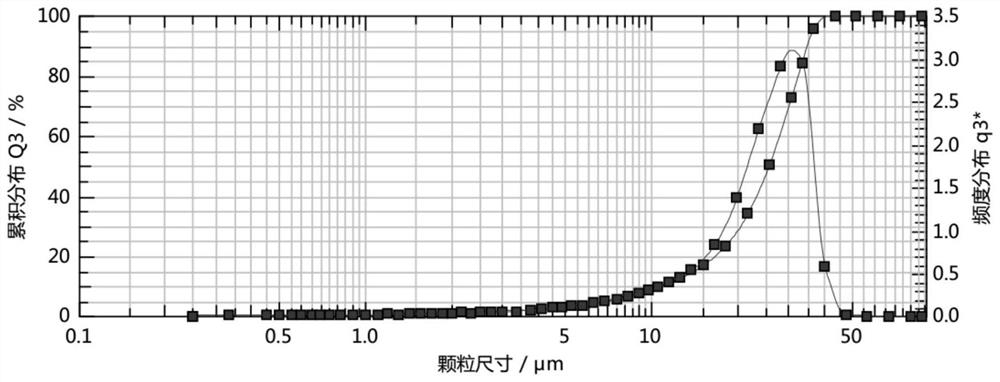

Co-doped modified lithium ion battery ternary positive electrode material and preparation method thereof

PendingCN113161534AUniform particle size distributionFlat surfaceCell electrodesSecondary cellsNickel saltManganese

The invention discloses a co-doped modified lithium ion battery ternary positive electrode material and a preparation method thereof, wherein the chemical general formula of the prepared material is Li(Ni0.5Co0.2Mn0.3)1-xAlx / 2Lix / 2O2-xFx, and x is 0-0.06. The preparation method is characterized by comprising the following steps: weighing a lithium salt, a nickel salt, a cobalt salt, a manganese salt, an aluminum salt and a non-metal villiaumite according to a molar ratio, then weighing citric acid, dissolving, adding into a mixed solution, stirring and evaporating to form sol, drying, presintering to obtain a precursor, and finally calcining at a high temperature to obtain the doping material. According to the invention, the preparation method is simple and convenient, and the obtained Al, Li and F co-doped positive electrode material is uniform in particle, moderate in particle size, high in crystallization degree and excellent in cycle performance at high temperature and high voltage, can be practically applied to the field of power batteries and is suitable for large-scale production.

Owner:JIANGNAN UNIV

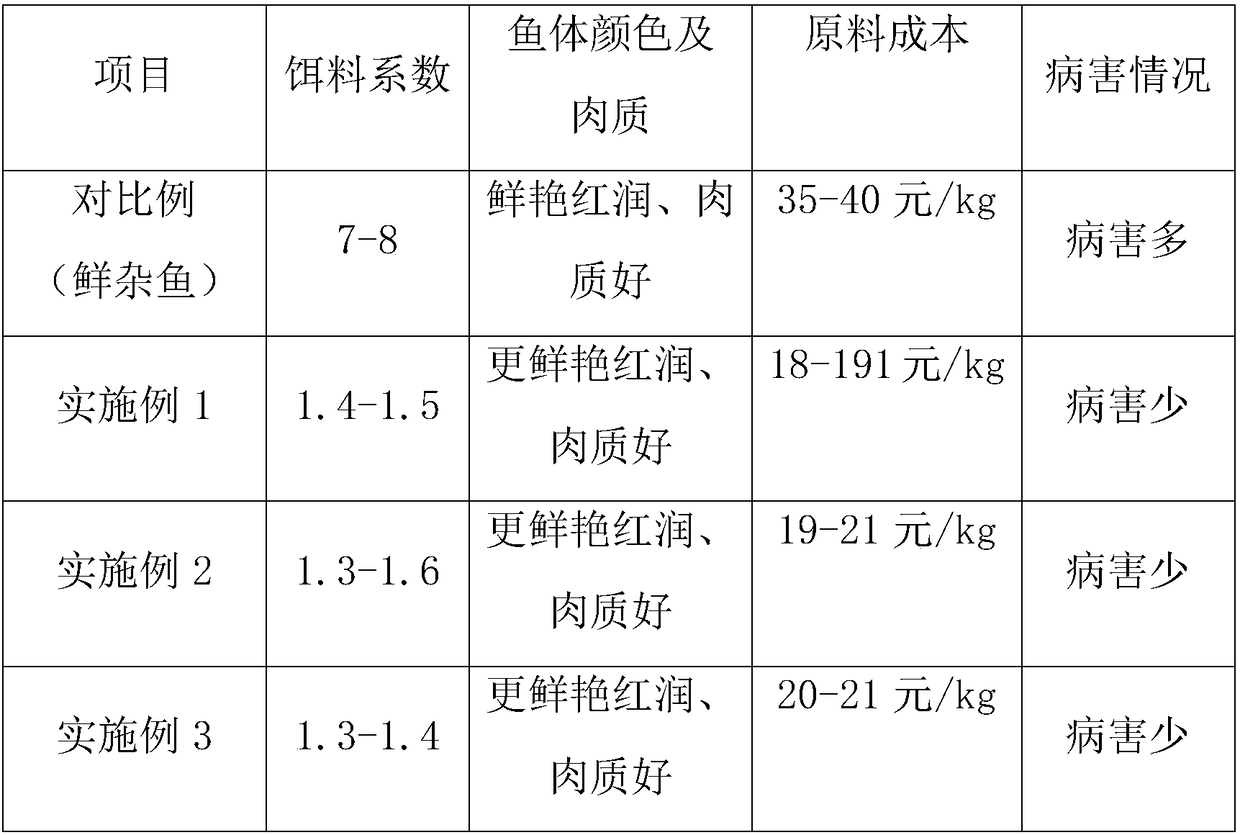

Artificial compound feed for seriola dumerili and preparation method thereof

InactiveCN108552435AIncrease appetiteImprove the quality of farmingClimate change adaptationAnimal feeding stuffDisease occurrenceFish meal

The invention relates to artificial fish bait, in particular to an artificial compound feed for seriola dumerili and a preparation method thereof. The feed is mainly prepared from the following components in parts by mass: 10-15 parts of wheat flour, 4-6 parts of starch, 3-6 parts of puffed soybean powder, 50-60 parts of fish meal, 10-15 parts of krill powder, 5-8 parts of fish oil, 0.5-1.5 partsof choline, 0.5-1.5 parts of a vitamin mixture and 0.5-1.5 parts of a mineral mixture. The artificial compound feed for seriola dumerili is specially designed for seriola dumerili, has the advantagesof low raw material cost and high bait utilization rate, is beneficial to improving the cultivation quality of the seriola dumerili and reducing the disease occurrence, and is easy to store and convenient for feeding.

Owner:福建高农饲料有限公司

Low-sugar baking filling and preparation method thereof

InactiveCN109662127AMake up for bad tasteReduce dosageBakery productsSucrose measurementWHITE KIDNEY BEAN

The invention discloses low-sugar baking filling and a preparation method thereof, and belongs to the field of food processing. The low-sugar baking filling is prepared from whole blueberry powder, white kidney bean powder and mashed white potato. The preparation method of the low-sugar baking filling comprises the processes of preparing the mashed while potatoes, weighing the materials and preparing the filling. The invention further discloses a mooncake. The low-sugar baking filling obtained through the preparation method of the low-sugar baking filling is adopted as filling. The whole blueberry powder and the white kidney bean powder are added to the filling containing the mashed while potatoes, saccharose can be replaced, the prepared filling has the fragrant and sweet taste, the tasteof the white potato filling can be improved, and therefore the taste of the low-sugar baking filling is smooth. The low-sugar baking filling is adopted as the filling of the mooncake, the sugar content of the mooncake and the generated sweet taste can be effectively reduced, the taste is unique and can be accepted by consumers more easily, and the sales of the mooncake is greatly improved.

Owner:HEFEI UNIV

A kind of europium-doped bismuth ferrite thin film and its preparation method and application

InactiveCN103938156BSimple structureEasy to operateVacuum evaporation coatingSputtering coatingLanthanumEuropium

The invention discloses a europium doped bismuth ferrite film, which comprises a silicon substrate with lanthanum nickelate as the buffer layer and a target material with a composition formula of Bi1-xEuxFeO3 (with x being greater than or equal to 0 and smaller than or equal to 0.07). The target material is deposited on the substrate. The invention also discloses a preparation method of the europium doped bismuth ferrite film. The method consists of: cleaning the substrate, placing the target material and the substrate in a film coating chamber, adjusting the pressure to less than 5*10<-4>Pa, raising the temperature of the substrate to 700DEG C at a speed of 10DEG C per minute; adjusting the sputtering pressure to 10Pa, maintaining the state for 10min under 700DEG C and an oxygen pressure of 10Pa, making adjustment to invert the substrate and rotate the target material in forward direction, keeping a 6cm distance between the substrate and the target material, employing a pulse laser to conduct film deposition for 60min and performing heat preservation for 30min, then conducting cooling at a speed of 20DEG C per minute to 200DEG C, and taking out the product, thus obtaining the europium doped bismuth ferrite film. The preparation method provided by the invention has the advantages of easily controllable reaction process and easily available raw materials. The europium doped bismuth ferrite film has significantly improved crystallization properties and electric leakage properties, and a smaller optical band gap, thus improving the photovoltaic properties of BiFeO3 films. The europium doped bismuth ferrite film has wide application prospects.

Owner:EAST CHINA NORMAL UNIV

A kind of preparation method of biapenem bulk drug

ActiveCN111875622BHigh purityThe status of impurities is clearAntibacterial agentsOrganic chemistryActivated carbonSolvent

The invention provides a method for preparing a biapenem bulk drug, the method comprising the following steps: 1) at a certain dissolution temperature T 1 2) The crude biapenem aqueous solution obtained in step 1) is controlled at T 1 or cool down to T 2 , add activated carbon, stir to decolorize, filter, and cool the filtrate to T 3 Standby; 3) the filtrate of step 2) gained is added dropwise to pre-cooling to T 4 4) growing crystals; 5) separating, washing and drying the crystals precipitated in step 4) to obtain the biapenem bulk drug.

Owner:SHENZHEN HAIBIN PHARMA +2

A kind of manufacturing method of high manganese steel seamless pipe

The invention relates to a manufacturing method for a seamless pipe, and in particular to a manufacturing method for a high manganese steel seamless pipe with high strength and corrosion resistance. The manufacturing method for the high manganese steel seamless pipe comprises the following steps that a high manganese steel ingot comprising, by weight percentage (%), 0.08-0.60% of C, 0.10-3.60% of Si, 15.00-28.00% of Mn, 0.02-4.50% of Al, no more than 0.045% of P, no more than 0.045% of S, 0.01-0.30% of Nb, 0.001-0.040% of N, 0.01-0.20% of Ti, 0.01-0.20% of V, and the balance Fe and inevitable impurities is kept warm for 6-8 hours at the temperature of 1150-1250 DEG C, the steel ingot is hot-forged into a cylindrical blank at the temperature of 850-1150 DEG C, then the cylindrical blank is covered with a heat preservation cover quickly for slow cooling, and the cylindrical blank is air-cooled to the room temperature 48 hours later by hoisting the cover away.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

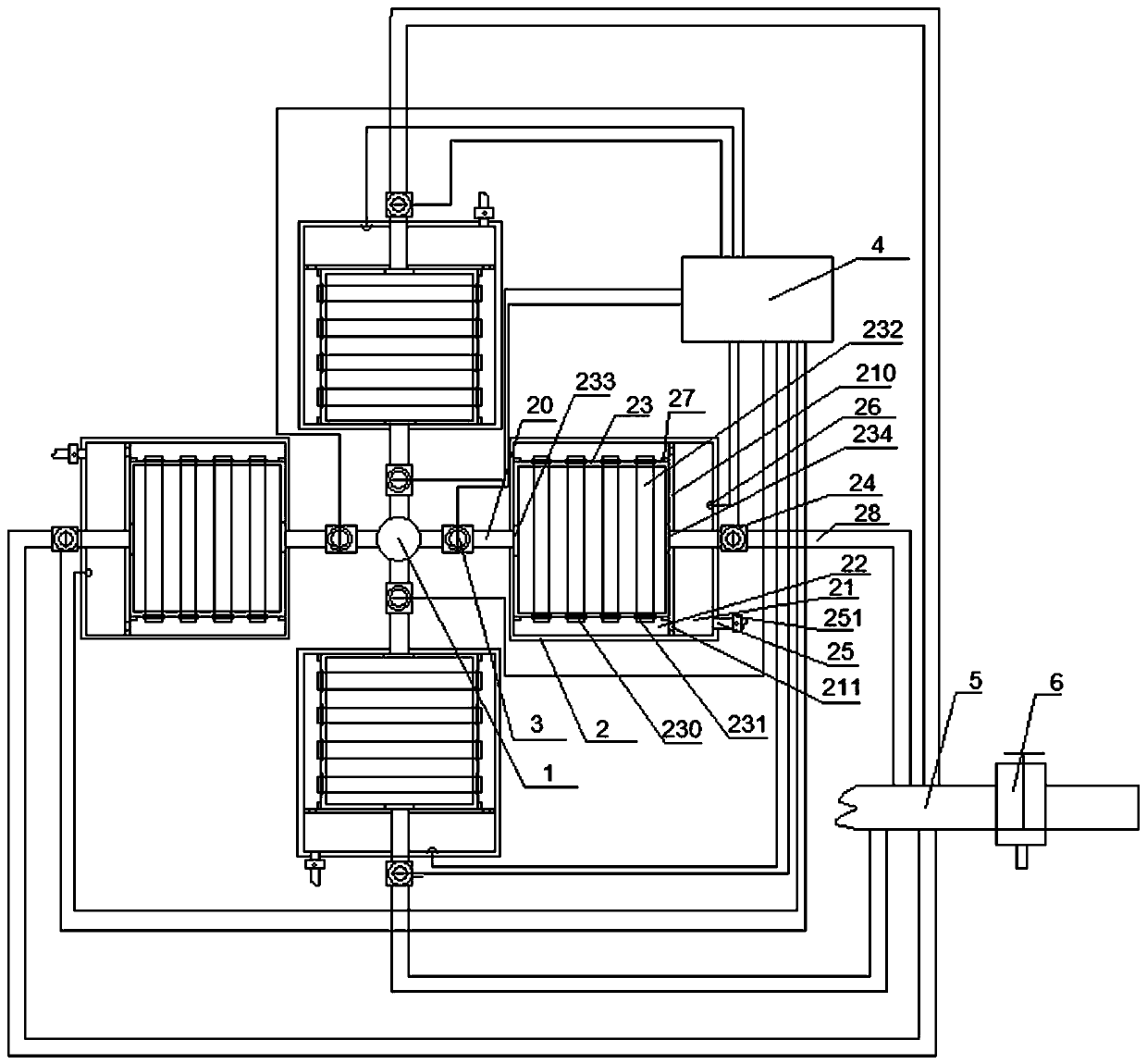

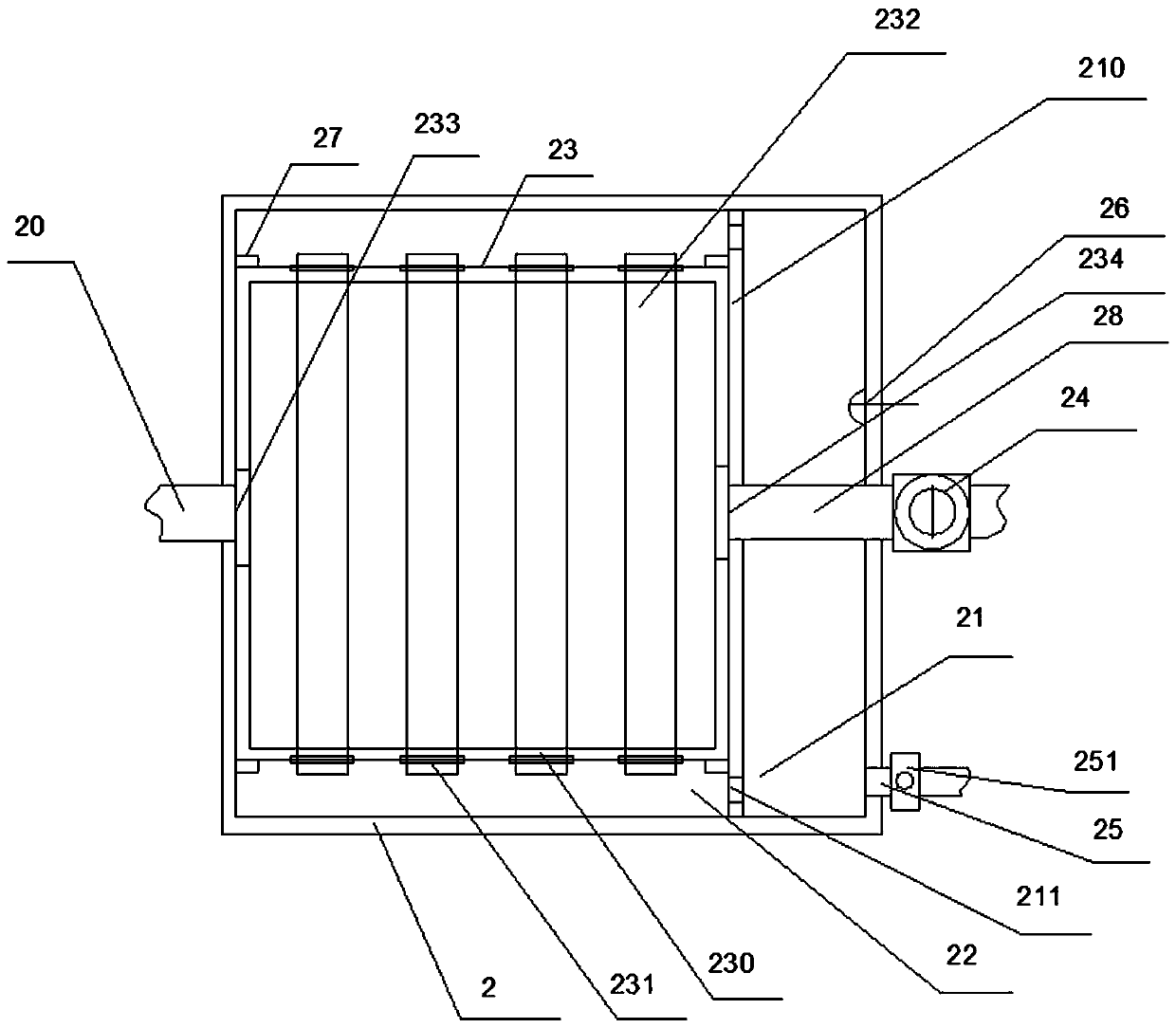

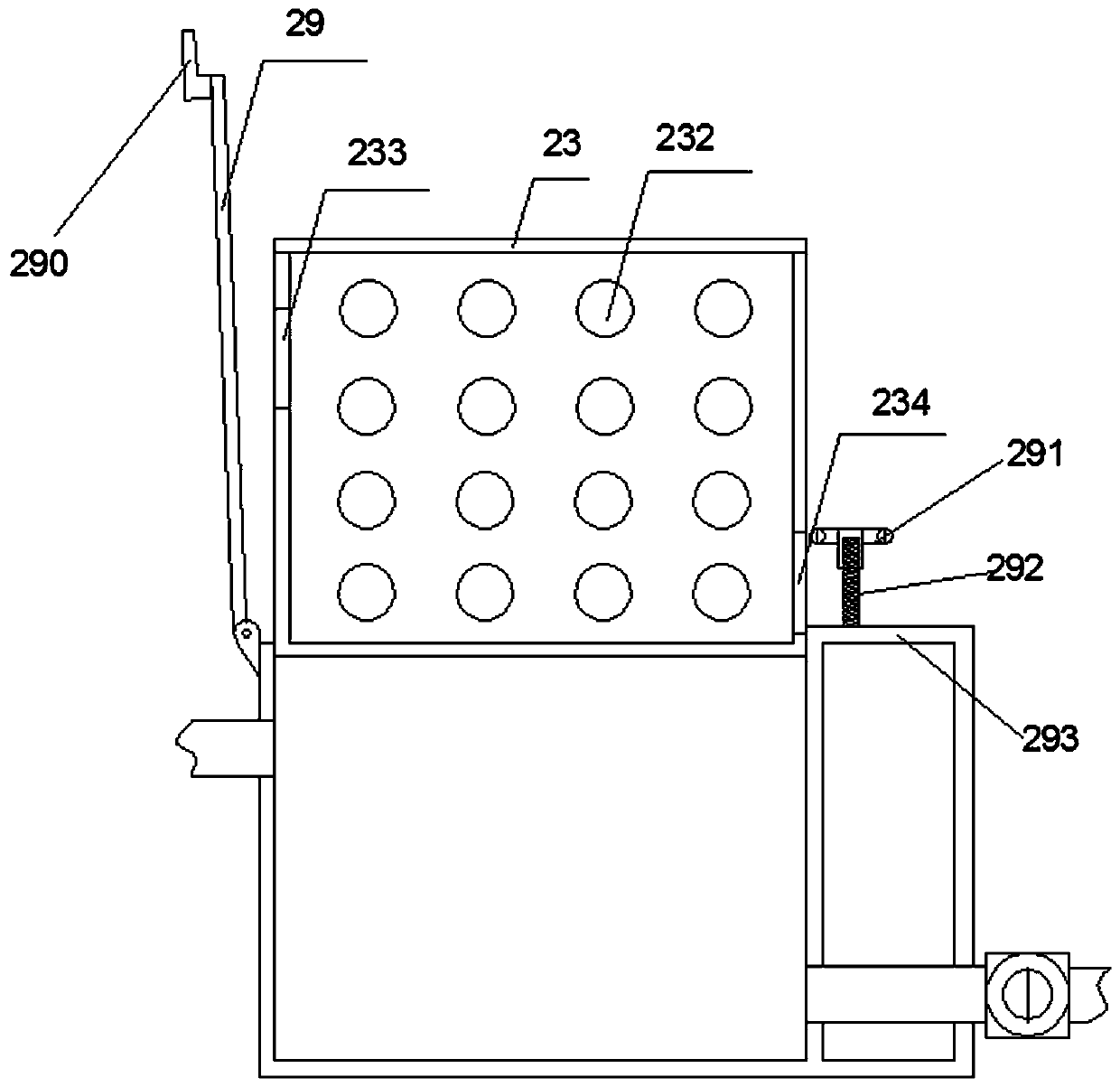

Concentration device for colloidal solution

ActiveCN109966922AHigh purityIncrease concentrationUltrafiltrationSilicon compoundsSocial benefitsColloidal silica

The invention relates to a concentration device for a colloidal solution. The device is characterized by comprising a total liquid inlet pipe, a total liquid outlet pipe and four filtering cylinders.A cabin wall is arranged in each filtering cylinder, each filtering cylinder is divided into a filtering cabin and a water-permeable cabin through the corresponding cabin wall, and each filtering cabin is provided with a liquid inlet pipe and a liquid outlet pipe; the liquid inlet pipes are connected with the total liquid inlet pipe, an electric colloid discharging valve is connected to each liquid outlet pipe, and multiple ultrafiltration core pipes are arranged in the filtering cabins; the two ends of each ultrafiltration core pipe penetrate through the cabin walls and enter the water-permeable cabins, and an electrical conductivity detector is arranged in each filtering cabin; each water-permeable cabin is provided with a purification liquid outlet. The concentration device for the colloidal solution has the advantages that the automation degree is high, by adopting multiple filtering cylinders, continuous filtering can be continuously conducted in turn, the obtained colloidal silica is large in particle and high in concentration, and the device has high social benefits and wide market prospects.

Owner:湖北金伟新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com