Manufacturing method for high manganese steel seamless pipe

A manufacturing method and technology of high manganese steel, applied in the field of manufacturing high manganese steel high strength corrosion resistant seamless pipes, can solve the problems of no high manganese austenitic steel seamless pipes, achieve uniform austenite structure and promote development , the effect of meeting the expansion performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

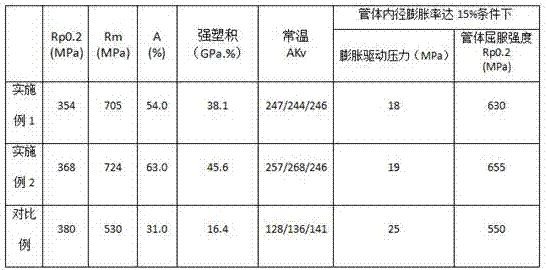

Examples

Embodiment 1

[0019] 1. The chemical composition weight percentage (%) of the steel used is: C content 0.13%, Si content 1.90%, Mn content 25.05%, Al content 3.18%, P content 0.013%, S content 0.008%, Nb content 0.25%.

[0020] 2. Forging

[0021] The steel ingot was heated at 1220°C for 8.5 hours; the starting forging temperature was 1060°C and the final forging temperature was 890°C. Forging a long round steel billet with a diameter of 290mm and 2.2m. After forging, the round billet is quickly buckled with a heat preservation cover for slow cooling, and then hangs the cover after 48 hours.

[0022] 3. Blank preparation

[0023] The round blank is peeled and sawed by a machined circular car to become a blank with a diameter of 277mm and a length of 700mm. A through hole with a diameter of 60mm is drilled in the center of the blank with a deep hole drill.

[0024] Blank outer diameter deviation -1mm.

[0025] Blank length deviation +3 mm.

[0026] Through hole concentricity 0.4mm;

[0...

Embodiment 2

[0047] 1. The furnace number and chemical composition of the material used are the same as in Example 1.

[0048] 2. Forging

[0049] The steel ingot was heated at 1240°C for a heating time of 8.5 hours; the starting forging temperature was 1060°C and the final forging temperature was 930°C. Forging a long round steel billet with a diameter of 360mm and 1.4m. After forging, the round billet is quickly buckled with a heat preservation cover for slow cooling, and then hangs the cover after 48 hours.

[0050] 3. Blank preparation

[0051] The round blank is peeled and sawed by a machined circular car to become a blank with a diameter of 344mm and a length of 1000mm. A through hole with a diameter of 80mm is drilled in the center of the blank with a deep hole drill.

[0052] Blank outer diameter deviation -1.5mm.

[0053] Blank length deviation +4 mm.

[0054] Through hole concentricity 0.4mm;

[0055] The surface roughness of the billet is Ra=4.2μm.

[0056] 4. Hot extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com