Ultralow-yield-ratio steel applied to single-rail turnout junction and production method of ultralow-yield-ratio steel

A production method and yield-strength ratio technology, which are applied in the field of extremely low yield-strength ratio steel for single track turnout and its production field, can solve the problems of inconvenience, unfavorable mass production, uneven performance, etc., and achieve the elimination of banding. Microstructure, simple heat treatment method, effect of microstructure refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An extremely low yield ratio steel for single track switch, its chemical element composition is shown in Table 1 by weight percentage.

[0027] The above-mentioned production method for extremely low yield ratio steel for a single track turnout specifically includes the following steps:

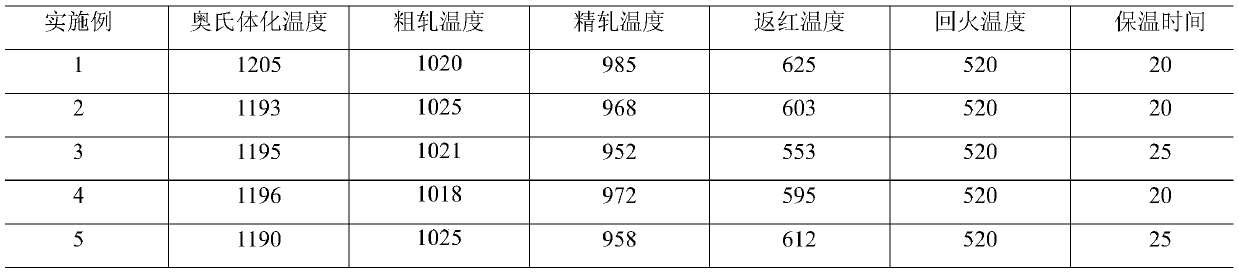

[0028] (1) Billet heating: the billet is heated in the furnace, and the austenitization temperature is 1150°C-1250°C;

[0029] (2) rolling

[0030] Rolling is done in two stages:

[0031] The first stage of rolling: the rough rolling temperature is 1000-1050 ℃, and high-pressure water is used to remove phosphorus 1-2 times during the rolling process;

[0032] The second stage of rolling: the finish rolling temperature is 950-1000°C, followed by laminar cooling, the reddening temperature is 550-650°C, and the cooling rate is 1-10°C / s;

[0033] (3) Heat treatment process: conduct tempering treatment, the tempering temperature is 450-600°C, the tempering holding time is 20-50min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com