Down-charging type light oil tanker vehicle

A technology of oil tanker and unloading type, which is applied in the direction of oil tanker, tanker, transport passenger car, etc. It can solve the problems of relatively high strength requirements for the bolster, failure to realize bottom unloading, and relatively high requirements for unloading facilities, so as to achieve guaranteed strength , Improve the stiffness and improve the effect of strength reserve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

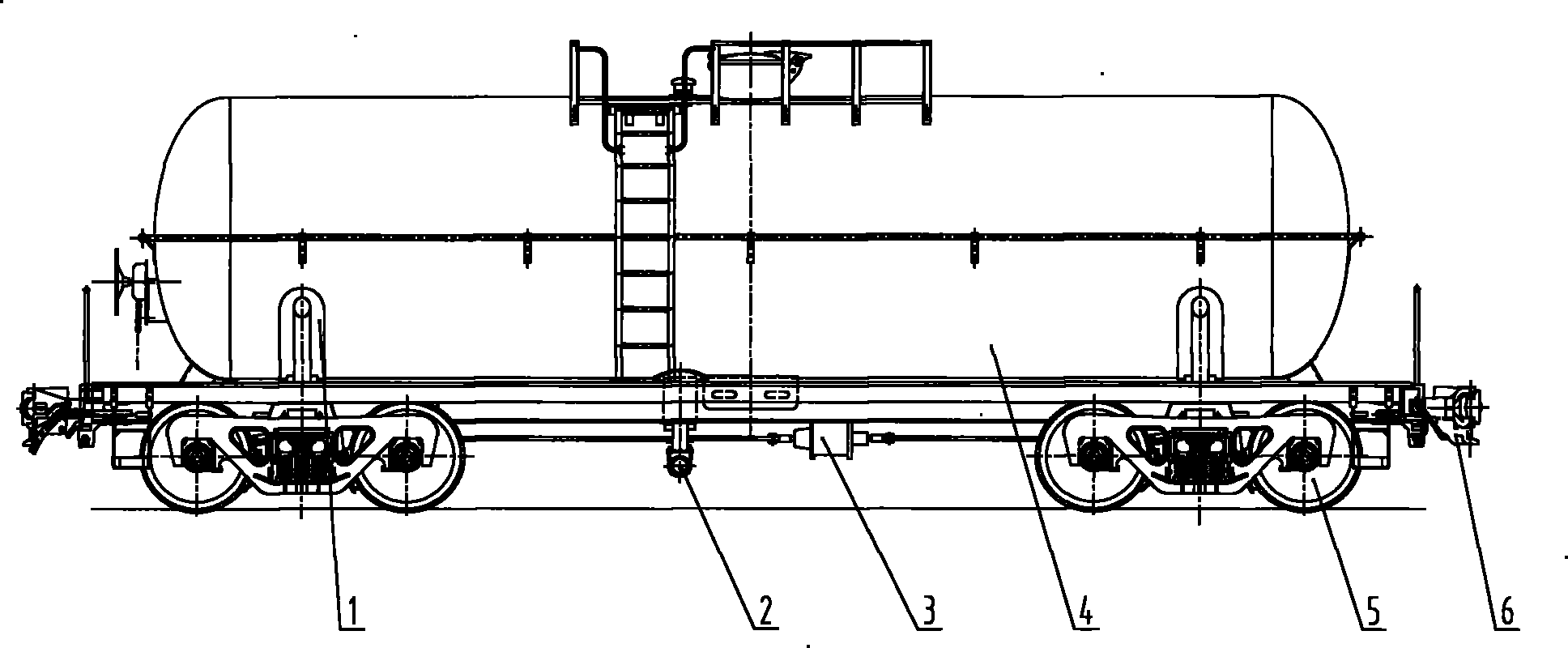

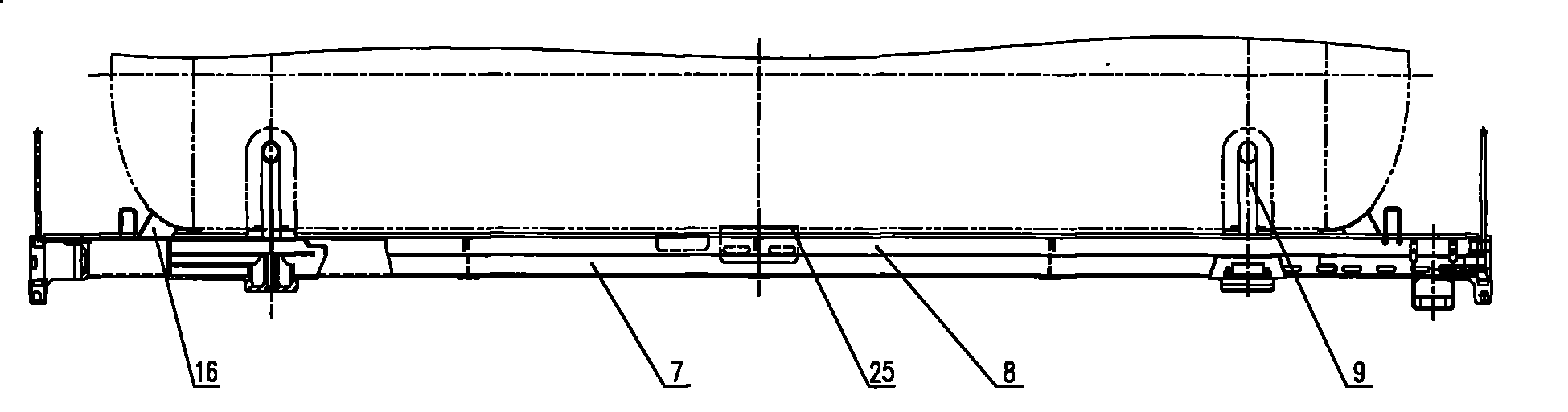

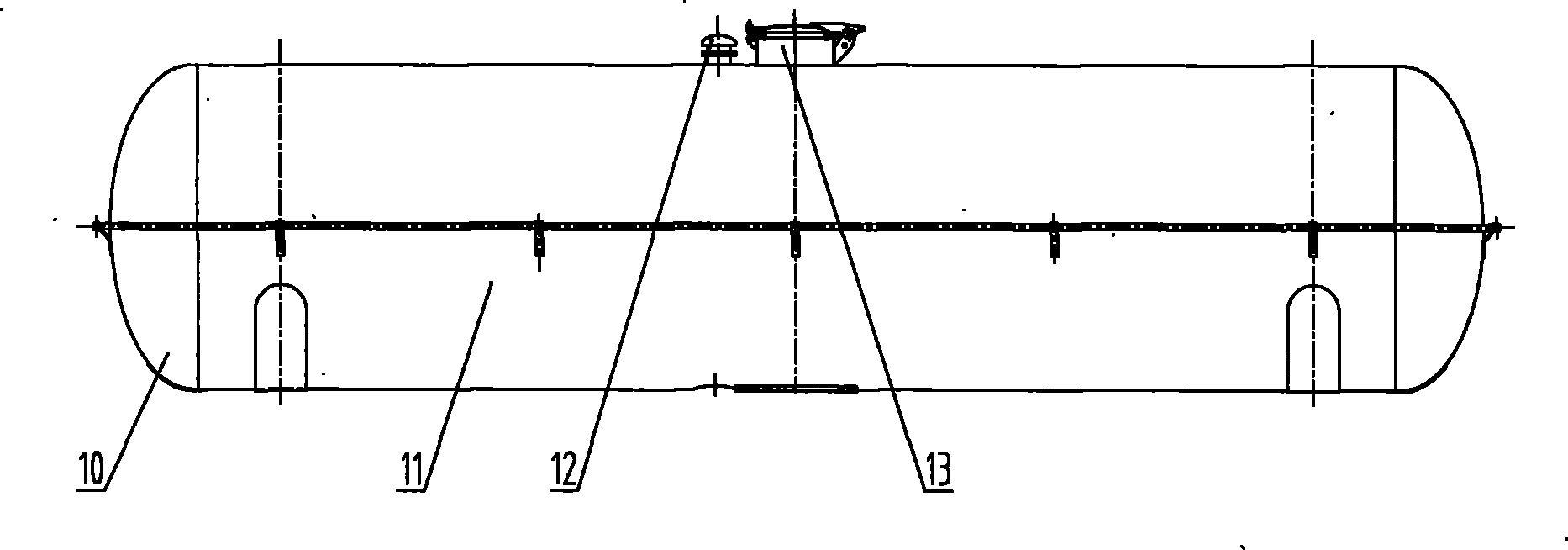

[0018] see Figure 1-Figure 7 , the present invention includes a bottom frame 1 and a tank body 4, and the tank body 4 is installed on the bottom frame 1. The underframe 1 includes a corbel 9 and a side beam 8. The corbel 9 is located at both ends of the underframe, and the side beams 8 are located on both sides of the underframe. The underframe 1 is provided with a bogie 5, a braking device 3 and a coupler buffer device. 6. The tank body 4 includes a cylinder body 11 and a sealing head 10. The sealing head 10 is located at both ends of the cylinder body 11 and is welded to the cylinder body 11. A manhole 13 and a safety valve 12 are provided above the tank body. The key technology is that the bottom frame 1 is also provided with a middle beam 7, which is located in the middle of the bottom frame along the longitudinal direction of the bottom frame, parallel to the side beam 8, and perpendicular to the corbel 9, forming a through-type middle beam. A support plate 25 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com