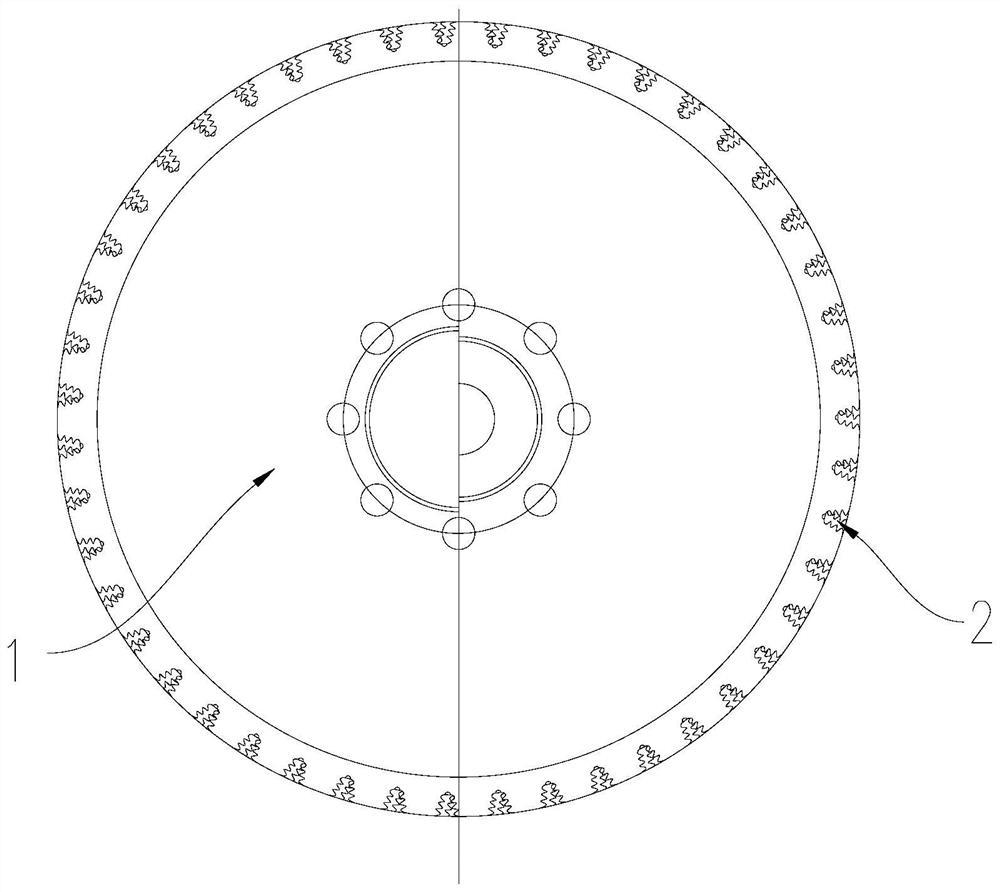

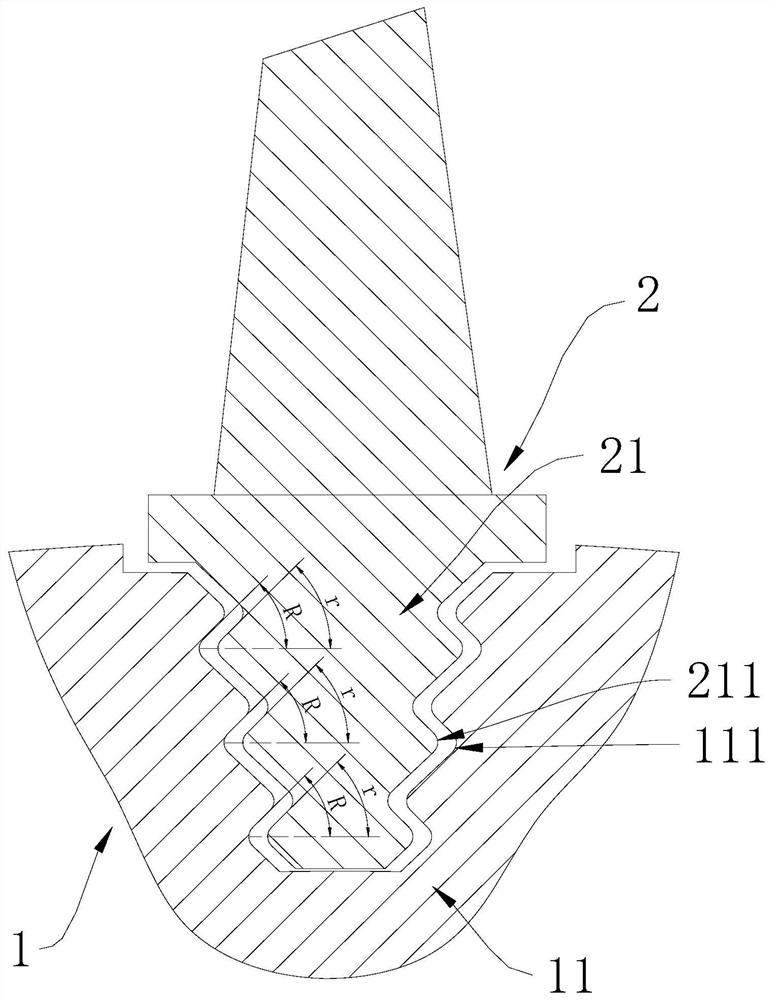

Flue gas turbine moving blade assembly and flue gas turbine

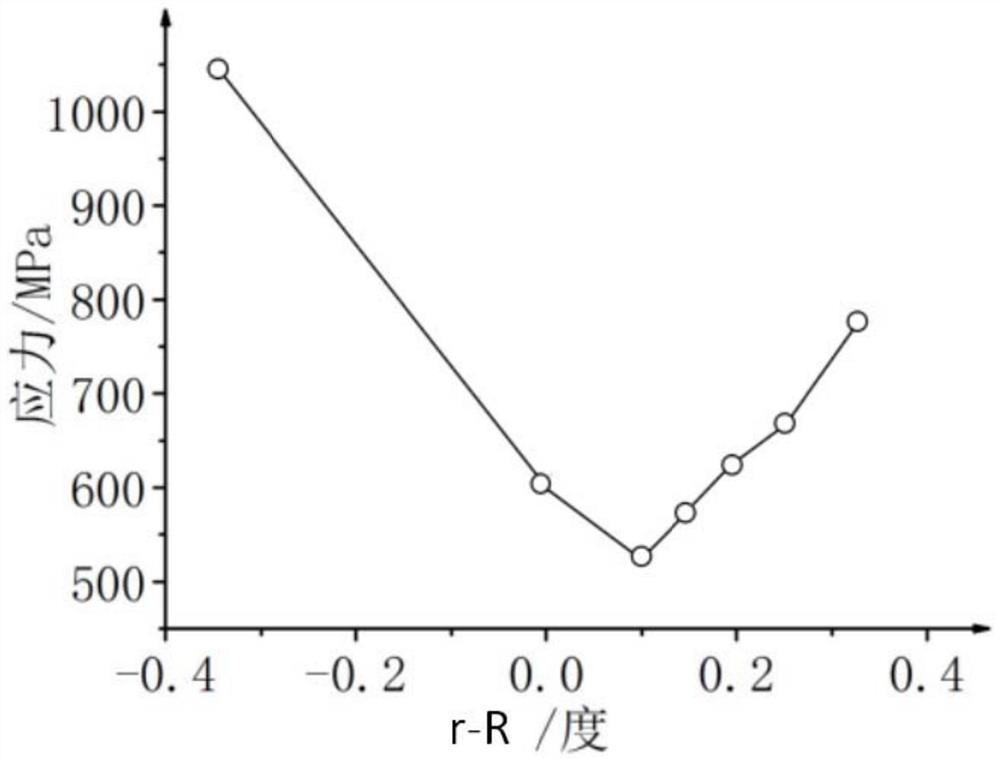

A moving blade and maneuvering technology, applied in the direction of machine/engine, blade supporting element, engine element, etc., can solve the problems of large stress, uneven force on tenon teeth and tenon roots, improve strength reserve, reduce stress concentration, Guarantee the effect of long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0030] In the present disclosure, unless stated otherwise, the used orientation words such as "axial and radial" generally refer to the definition under the normal operation of the flue gas turbine moving blade assembly provided by the present disclosure, relative to In terms of the center of rotation of the wheel 1, "inside" and "outside" refer to the inside and outside of the contours of the corresponding components. In addition, the terms "first", "second", and the like used in the present disclosure are for distinguishing one element from another, and do not have sequence or importance. When the following description refers to the accompanying drawings, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com