Bogie for goods train with large axle load and low dynamic action

A railway freight car, low-power technology, applied in the field of railway freight car bogies, can solve the problems of vehicle performance degradation, complex structure, short maintenance period, etc., and achieve the effect of reducing unsprung mass, high strength, and reducing contact friction pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

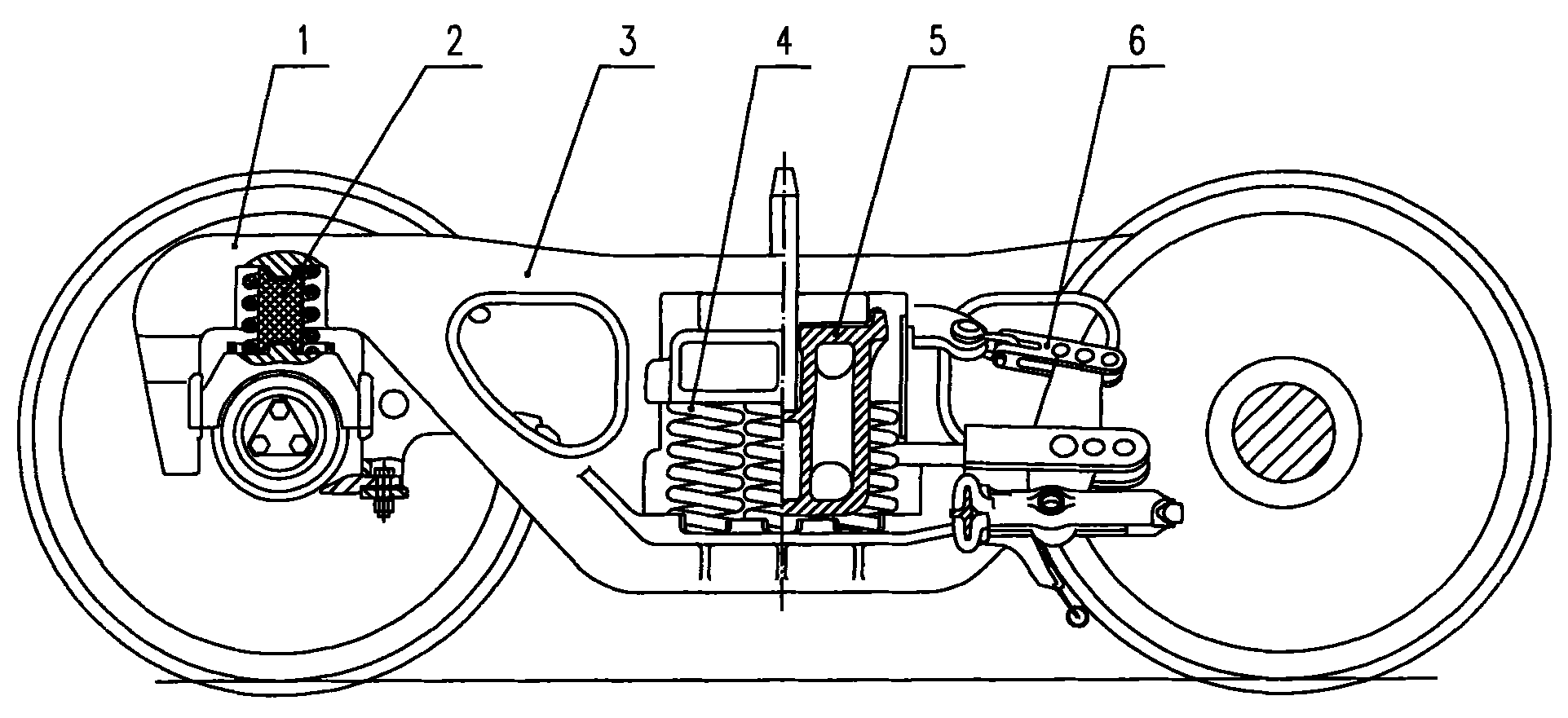

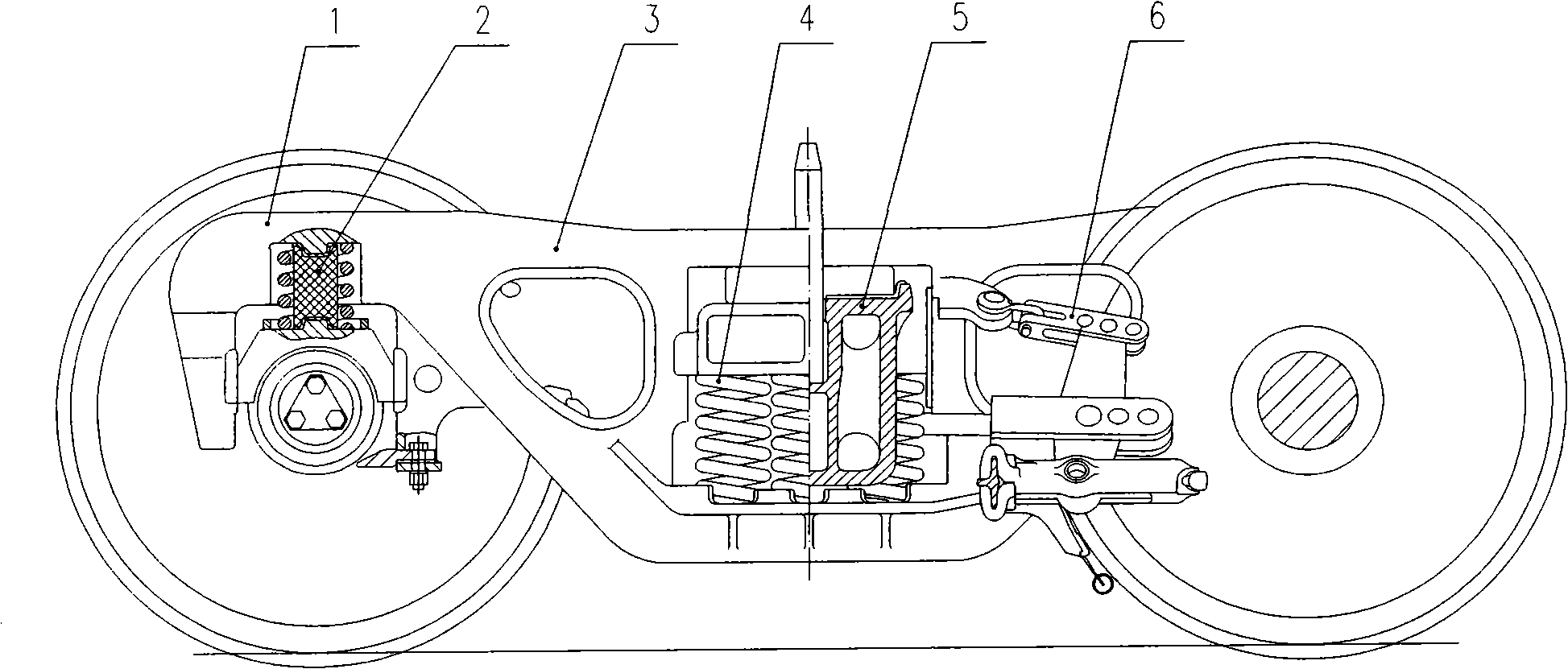

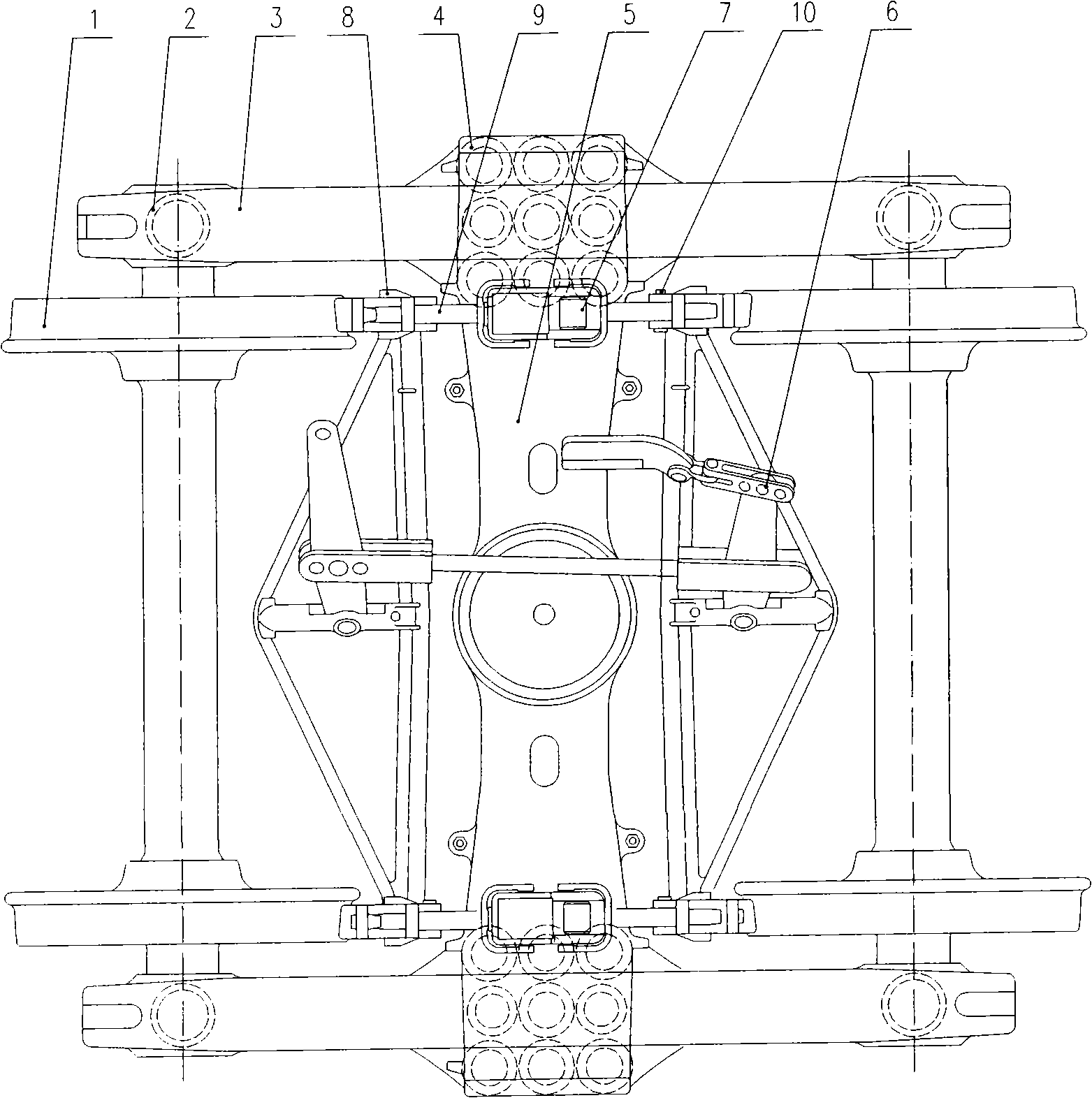

[0022] As shown in Fig. 1 and Fig. 2, the railway freight car bogie with large axle load and low power effect of the present invention is the same as the prior art, and also includes two wheelsets 1, four primary suspension devices 2, two side frames 3, Two secondary suspension devices 4, a bolster 5, a foundation braking device 6 and two side bearings 7. The bolster 5 is installed on the side frame 3 through the secondary suspension device 4 , the side bearing 7 is arranged in the side bearing box 18 on the bolster, and the side frame 3 is installed on the wheel set 1 through the primary suspension device 2 . The key technology of the present invention is that the foundation braking device 6 is suspended on the bolster suspender mounting seat 9 through four brake shoe support suspenders 8 and suspender pins 10, and the original chute type is changed to a suspension In this way, the foundation braking device 6 is placed on the secondary suspension device 4, and the unsprung ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com