Soil conditioner using biomass power plant ash as main raw material, its preparation and application method

A technology of biomass power plant ash and soil conditioner, which is applied in the application, fertilizer mixture, fertilization device and other directions, can solve the problems of not timely and reasonable utilization of power plant ash, consumption of acid resources and energy, and waste of resources, etc., and achieves a small bulk density. , Improve the utilization rate, the effect of strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Put 850kg of biomass power plant ash, 50kg of sawdust and 100kg of clay into the mixer, add 200kg of tap water, mix well, and the pH after mixing is greater than 10;

[0027] 2. Use a disc granulator to granulate, the particle size is 0.1-5mm, and the granulation shape is spherical;

[0028] 3. In the dryer, keep the temperature at 75°C and bake until the water content is 10% by mass;

[0029] 4. Sieve to remove lumps with a particle size larger than 5mm and powders with a particle size smaller than 0.1mm, and pack them in 50kg bags for use;

[0030] 5. Apply 100kg per mu evenly to the red soil, plow the ground and mix it into the topsoil of about 0-20cm;

[0031] 6. Measured one month later, the average soil pH increased from 5.0 to 6.3.

Embodiment 2

[0033] 1. Put 900kg of biomass power plant ash, 70kg of sawdust and 30kg of modified lignin into a mixer, add 230kg of tap water, and mix well;

[0034] 2. Use an extrusion granulator to granulate, the particle size is 0.1-5mm, and the shape of the granulation is irregular pellets;

[0035] 3. In the dryer, keep the temperature at 100°C, and bake until the water content is 9%;

[0036] 4. Sieve to remove lumps with a particle size larger than 5mm and powders with a particle size smaller than 0.1mm, and pack them in 50kg bags for use;

[0037] 5. Apply 110kg per mu evenly to the red soil, plow the ground and mix it into the topsoil of about 0-22cm;

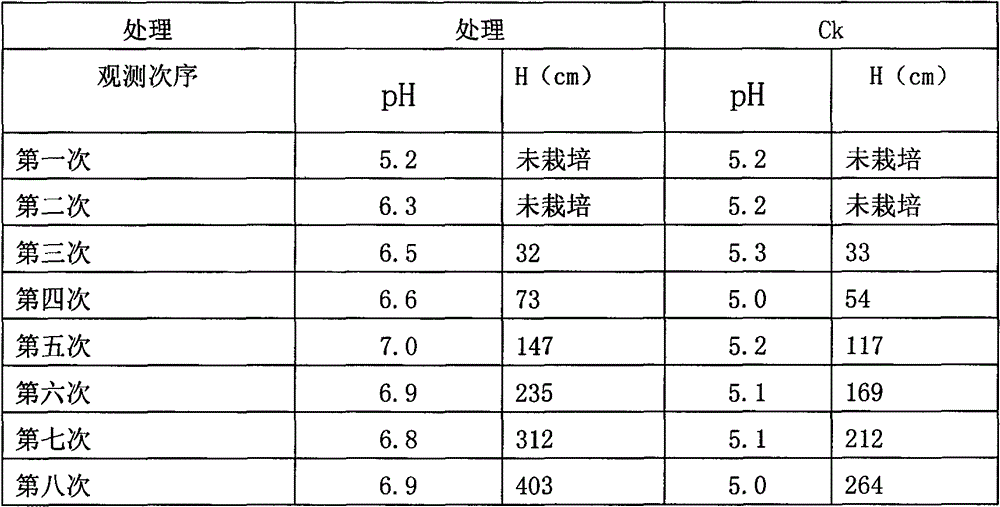

[0038] 6. One month later, the average pH of the soil increased from 5.2 to 6.8, and the growth of the planted Binagrass was significantly better than that of the unimproved soil.

Embodiment 3

[0040] 1. Put 860kg of biomass power plant ash, 100kg of sawdust and 40kg of modified starch into a mixer, add 260kg of tap water, and mix well;

[0041] 2. Use a drum granulator to granulate, the particle size is 0.1-5mm, and the granulation shape is spherical;

[0042] 3. In the dryer, keep the temperature at 150°C and bake until the water content is 8%;

[0043] 4. Sieve to remove lumps with a particle size larger than 5mm and powders with a particle size smaller than 0.1mm, and pack them in 50kg bags for use;

[0044] 5. Evenly apply 110kg per mu of land to the red soil, and at the same time apply fertilizer, turn the ground to mix it into the topsoil of about 0-22cm;

[0045] 6. One month later, the soil pH value increased from 5.5 to 7.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com