Europium doped bismuth ferrite film, preparation method and application thereof

A bismuth ferrite, thin film technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of thin film leakage, large band gap, etc., to improve photovoltaic performance and reduce optical band gap , the effect of improving the leakage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the bismuth ferrite thin film doped with europium proposed by the present invention comprises the following steps:

[0038] (1) Target material: select Bi with a purity of 99.99% 1-x Eu x FeO 3 Target, 0≤x≤0.07.

[0039] (2) Substrate: use lanthanum nickelate as the buffer layer of the silicon substrate as the substrate, first use detergent to remove grease, then use acetone to remove the residue of detergent, then put it in alcohol for ultrasonication for 30 minutes, and finally put it in After ultrasonication in ionized water for 30 min, it was taken out and stored in alcohol solution.

[0040] (3) Vacuuming: place the target and substrate in the coating chamber, and use a mechanical pump and a molecular pump to pump the vacuum chamber to a pressure of 5×10 -4 below pa.

[0041] (4) Heating the substrate:

[0042] Turn on the heating equipment, and control the substrate by computer to heat the substrate at a rate of 10°C per minute.

...

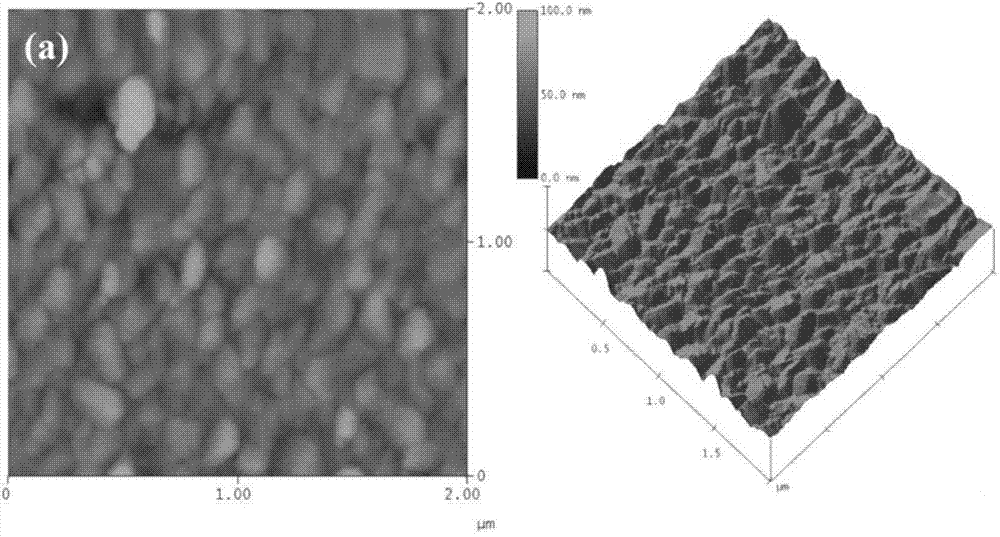

Embodiment 1

[0051] (1) Selection of target material: BiFeO with a purity of 99.99% is used 3 target;

[0052] (2) Cleaning the silicon substrate with lanthanum nickelate as a buffer layer: this substrate can be prepared on a commercial silicon substrate by a sol-gel method. First use detergent to remove grease, then use acetone to remove the residue of detergent, then put it in alcohol for 30 minutes, and finally put it in deionized water for 30 minutes and take it out;

[0053] (3) Vacuuming: the BiFeO 3 The target and the silicon substrate with lanthanum nickelate as the buffer layer are placed in the coating chamber, the substrate is fixed on the substrate disk with silver paste, and the vacuum is pumped to a pressure of 5×10 by using a mechanical pump and a molecular pump. -4 Below Pa;

[0054] (4) Substrate heating: Turn on the heating equipment and control it with a computer to raise the temperature at 10°C per minute to 700°C;

[0055] (5) When the temperature reaches the prese...

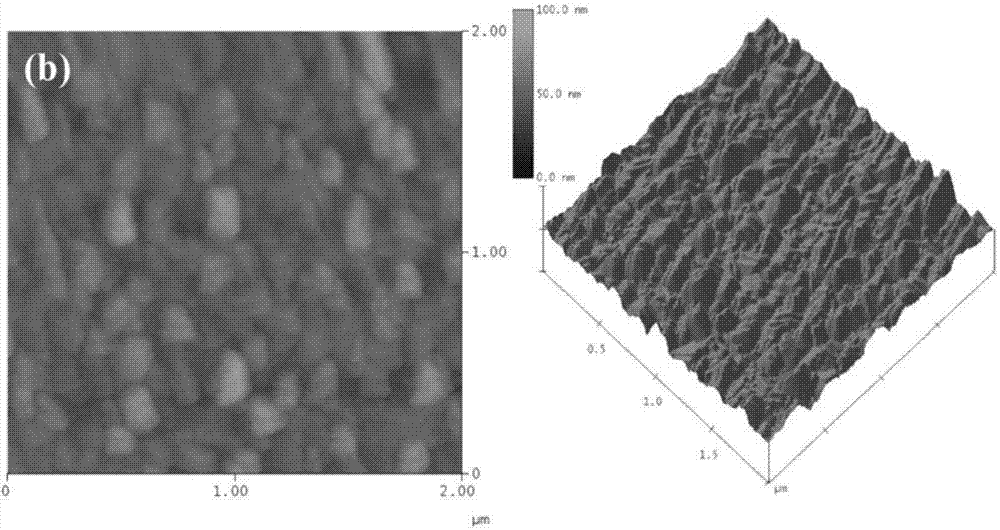

Embodiment 2

[0062] (1) Selection of target material: Bi with a purity of 99.99% is used 0.97 Eu 0.03 FeO 3 target;

[0063] (2) Clean the silicon substrate with lanthanum nickelate as the buffer layer: first use detergent to remove grease, then use acetone to remove the residue of detergent, then put it in alcohol for 30 minutes, and finally put it in deionized water for 30 minutes. take out;

[0064] (3) Vacuuming: the Bi 0.97 Eu 0.03 FeO 3 The target and the silicon substrate with lanthanum nickelate as the buffer layer are placed in the coating chamber, the substrate is fixed on the substrate disk with silver paste, and the vacuum is pumped to a pressure of 5×10 by using a mechanical pump and a molecular pump. -4 Below Pa;

[0065] (4) Substrate heating: Turn on the heating equipment and control it with a computer to raise the temperature at 10°C per minute to 700°C;

[0066] (5) When the temperature reaches the preset value, open the oxygen channel, rush in oxygen with a purit...

PUM

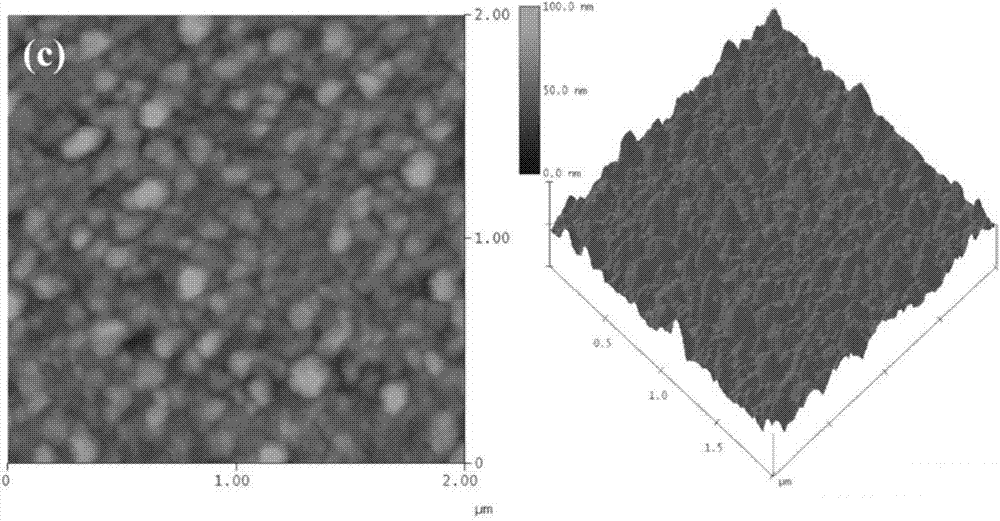

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com