Metal anticorrosive paint and preparation method thereof

A metal anti-corrosion and coating technology, applied in anti-corrosion coatings, coatings, grain processing and other directions, can solve the problems of coating cracking, uneven technical means, loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A kind of metal anticorrosion coating, its composition is as follows by mass parts:

[0061] 10-15 parts of butyl methacrylate, 4-5 parts of cyclohexanone, 3-4 parts of titanium dioxide, 1-2 parts of epoxy resin curing agent, 3-6 parts of propylene glycol phenyl ether, 10-15 parts of pentaerythritol, pigment 8-15 parts of filler, 5-6 parts of polyether silicone oil, 1-2 parts of polytetrafluoroethylene wax, 1-2 parts of titanate coupling agent, 4-6 parts of leveling agent, 1-2 parts of zinc phosphate, 15-25 parts of butyl acetate, 6-12 parts of graphite, 8-10 parts of hydroxypropyl methylcellulose, 2-4 parts of additives, 2-3 parts of xylene, 35-50 parts of thermosetting high-salt resin, phenolic ring 15-25 parts of epoxy resin and chloroether resin; wherein, novolac epoxy resin and chloroether resin are mixed in a mass ratio of 3:2;

[0062] It can realize the method for metal anticorrosion coating preparation as follows:

[0063] Step A1: Add butyl methacrylate, cyc...

Embodiment 2

[0071] The thermosetting high-salt resin is made from the following proportions: rosin is 30% of 35-50 parts of thermosetting high-salt resin, shellac is 30% of 35-50 parts of thermosetting high-salt resin, and industrial salt is 35% of thermosetting high-salt resin. - 40% composition of 50 parts;

[0072] The concrete preparation method of this thermosetting high-salt resin is as follows:

[0073] B1: Preparation of rosin, extracting high-viscosity exudate from Longleaf Pine, Cuban Pine and Loblolly Pine, and then extracting by distillation, while dispersing the volatile attachment liquid, and retaining the remaining hard resin;

[0074] The shellac is prepared by collecting the rubber blocks from the lac tree, removing the attached impurities, crushing the original gum, and further screening and filtering, stirring and rinsing, finally going through centrifugal dehydration, and drying into granules;

[0075] Industrial salt preparation, take the filtered industrial salt cry...

Embodiment 3

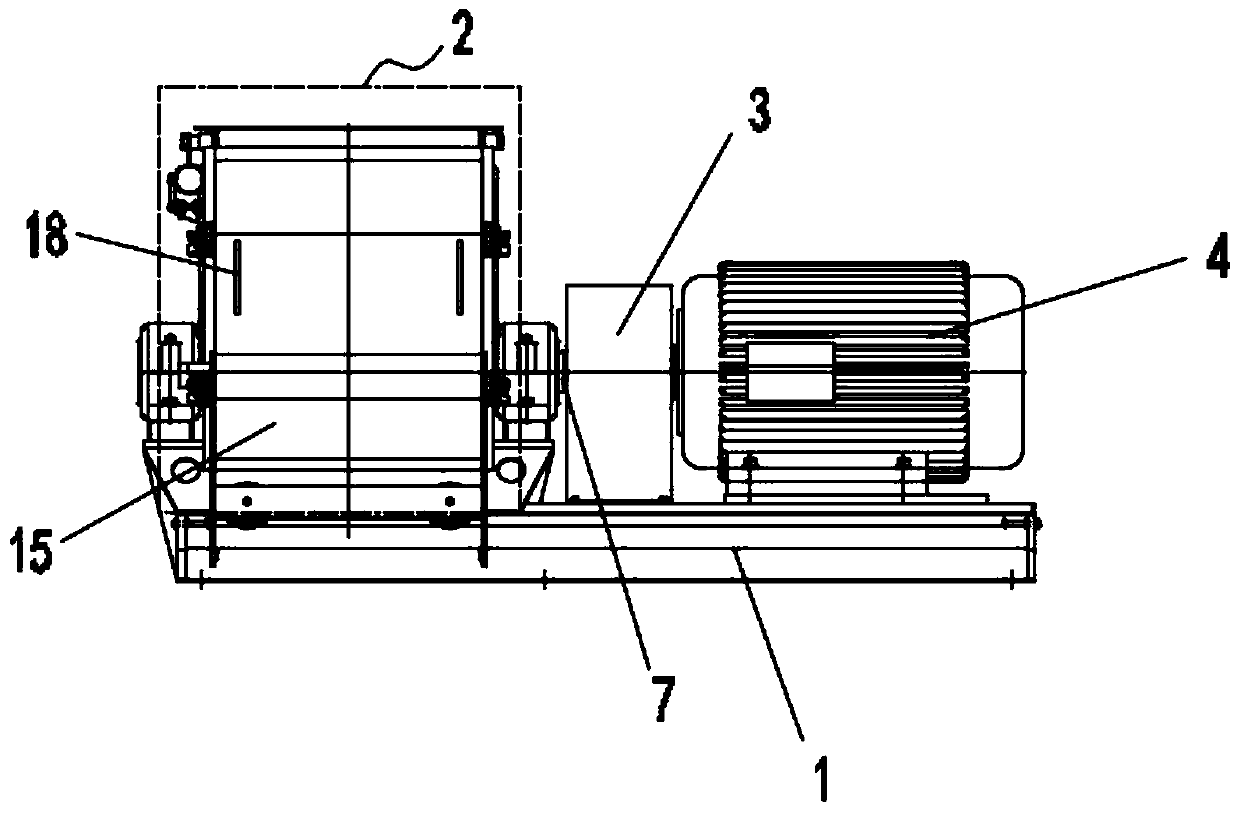

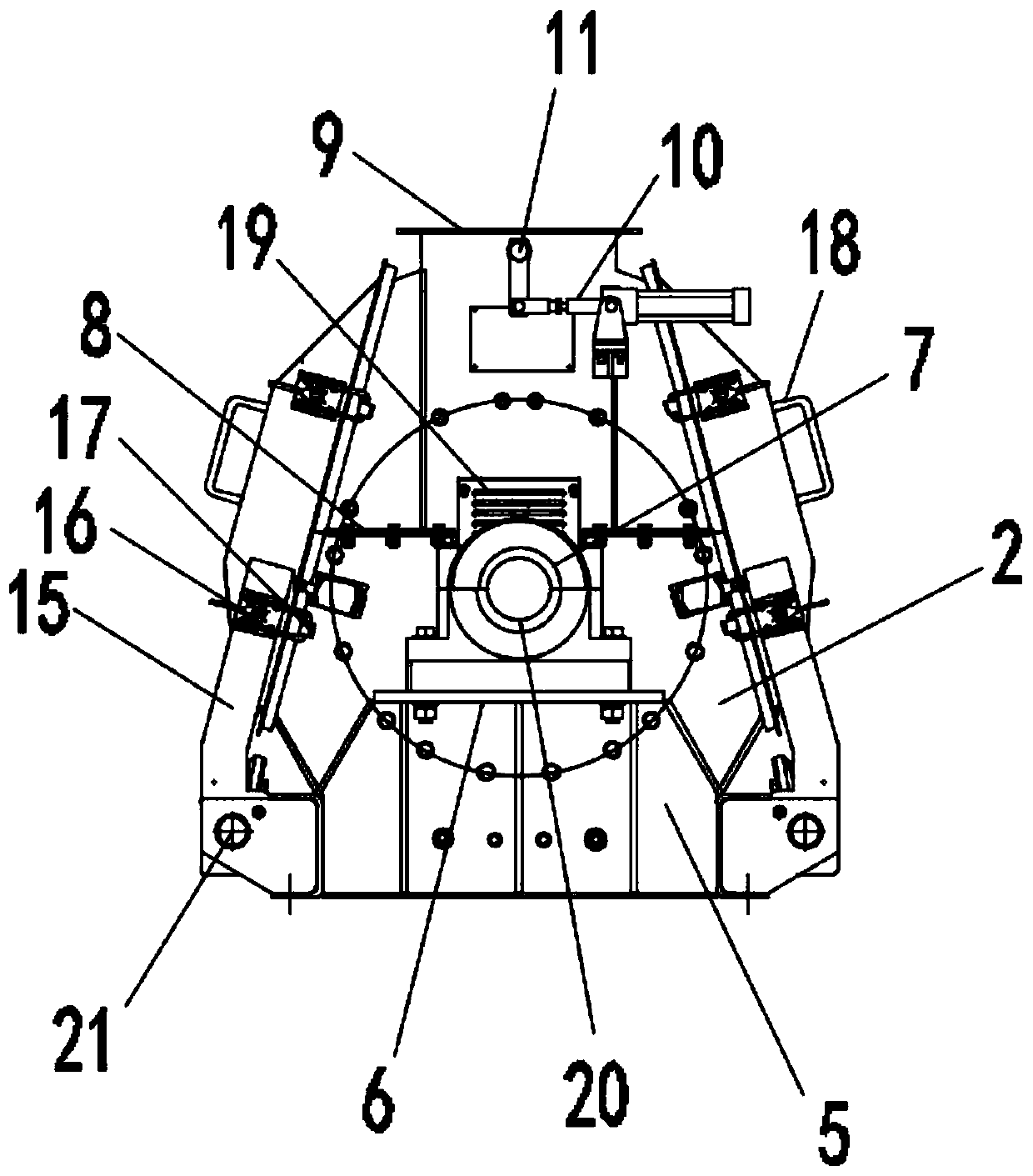

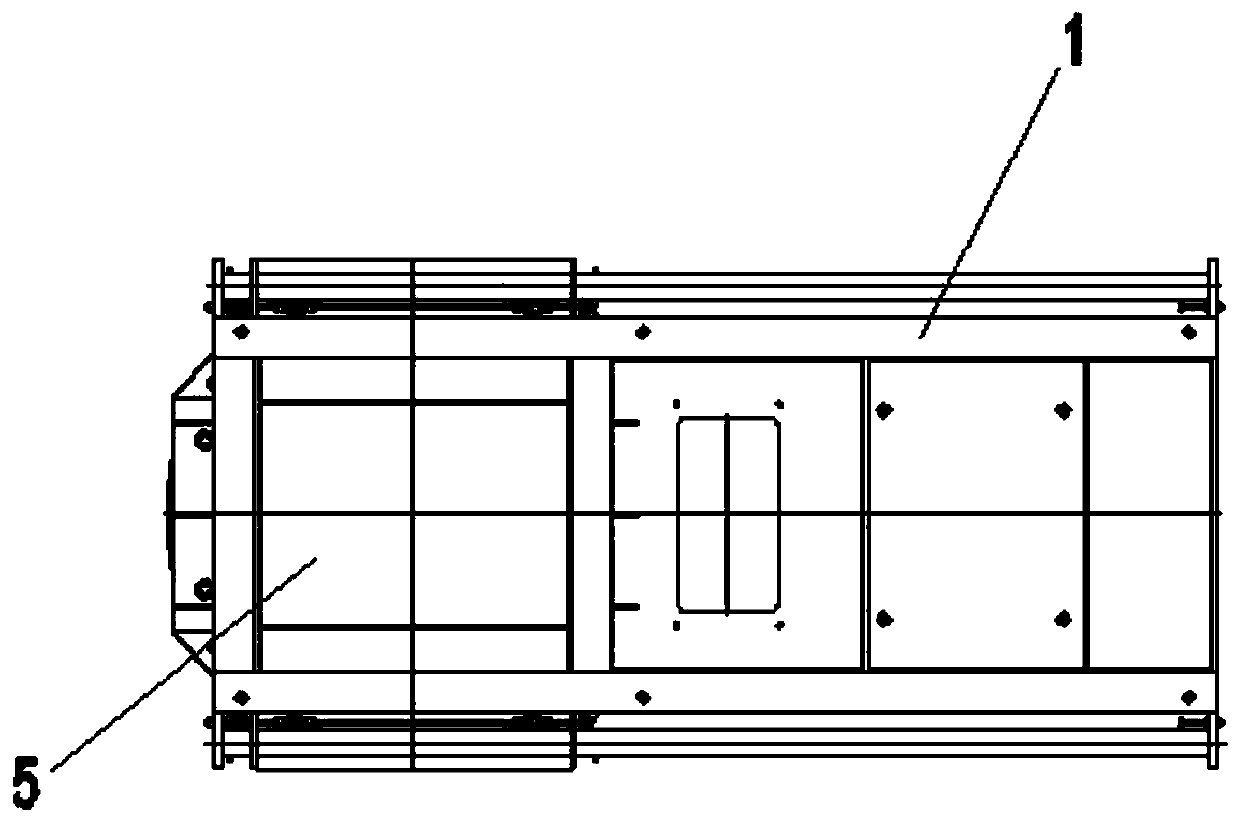

[0080] The high-salt cage pulverizer in step B2 comprises a fixed base 1, on which a casing 2, a transmission 3 and a motor 4 are fixed, and the transmission 3 is a conventional gear transmission drive device, which mainly plays a role in regulating the output of the motor 4. Frequency rotation power, so as to adjust to meet the processing speed requirements of the high-salt cage crusher, the transmission 3 is fixedly installed between the chassis 2 and the motor 4, and the bottom center of the chassis 2 is fixed with a collection bin 5, and the collection bin 5 attached by figure 2 It is shown that there is a possibility of collision with the flying blade 8, but in fact it is due to the figure 2 Due to the side view, its structure does not interfere with each other. At the same time, it is the same for the conveying roller 7 and the convection gate 19. Both the conveying roller 7 and the convection gate 19 are outside the cabinet 2, and the inside of the cabinet 2 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com