Spherical tantalum powder as well as preparation method and application thereof

A technology of tantalum powder and spherical shape, which is applied in the field of spherical tantalum powder. It can solve the problems affecting the performance of capacitor tantalum powder, the process parameters are not adjusted well, and the particle size is uncontrollable, so as to achieve high purity, shorten the process flow, and reduce The effect of pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

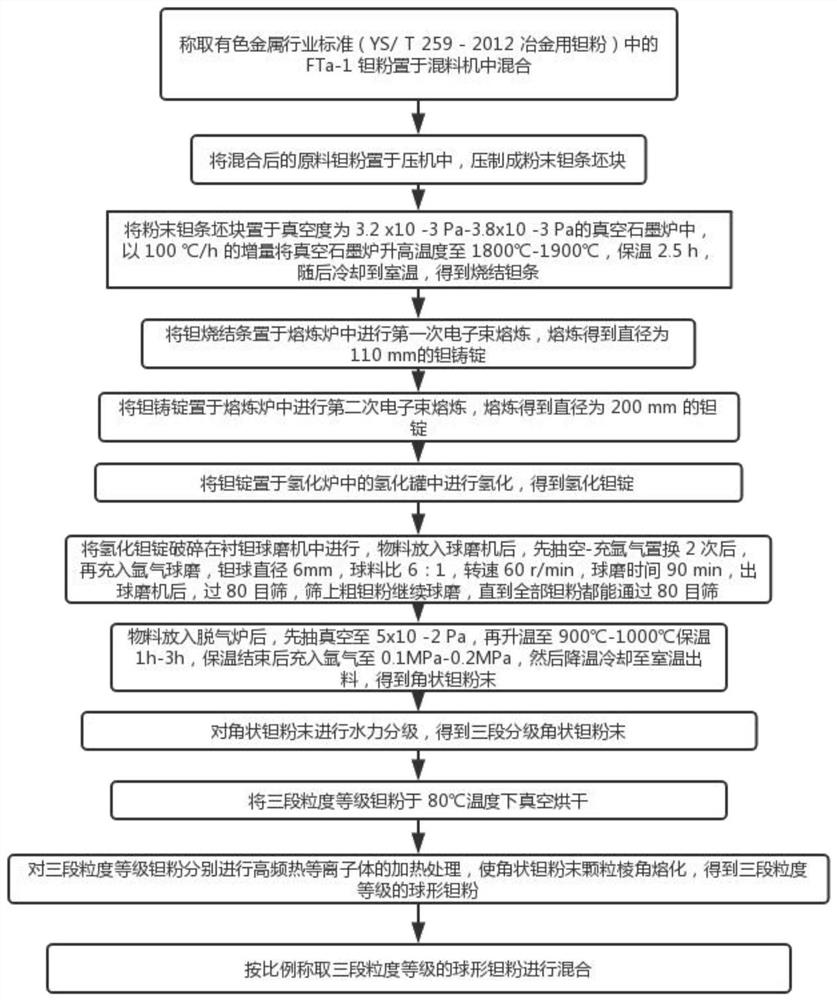

Embodiment 1

[0041]Weigh the FTa-1 tantalum powder in the non-ferrous metal industry standard (YS / T 259-2012 tantalum powder for metallurgy) and mix it in a mixer; put the mixed raw tantalum powder in a press, and press it into powdered tantalum powder Bar compact; place the powdered tantalum billet in a vacuum of 3.2x10 -3 In the vacuum graphite furnace of Pa, raise the temperature of the vacuum graphite furnace to 1800°C with an increment of 100°C / h, keep it warm for 2.5h, and then cool to room temperature to obtain sintered tantalum bars;

[0042] Put the tantalum sintered strip in the melting furnace for the first electron beam melting. The parameters of the first electron beam melting are: the vacuum degree of the melting furnace is 5x10 -3 Pa, the voltage is 20KV, the current is 5A, the feed rate is 19kg / h, and the cooling time is 3h to melt to obtain a tantalum ingot with a diameter of 110mm;

[0043] Put the tantalum ingot in the melting furnace for the second electron beam meltin...

Embodiment 2

[0060] Weigh the FTa-1 tantalum powder in the non-ferrous metal industry standard (YS / T 259-2012 tantalum powder for metallurgy) and mix it in a mixer; put the mixed raw tantalum powder in a press, and press it into powdered tantalum powder Bar compact; place the powdered tantalum billet in a vacuum of 3.8x10 -3 In the vacuum graphite furnace of Pa, raise the temperature of the vacuum graphite furnace to 1900°C with an increment of 100°C / h, keep it warm for 2.5h, and then cool to room temperature to obtain sintered tantalum bars;

[0061] Put the tantalum sintered strip in the melting furnace for the first electron beam melting. The parameters of the first electron beam melting are: the vacuum degree of the melting furnace is 5x10 -3 Pa, the voltage is 22KV, the current is 7A, the feed rate is 22kg / h, and the cooling time is 4h for smelting to obtain a tantalum ingot with a diameter of 110mm;

[0062] Put the tantalum ingot in the melting furnace for the second electron beam ...

Embodiment 3

[0079] Weigh the FTa-1 tantalum powder in the non-ferrous metal industry standard (YS / T 259-2012 tantalum powder for metallurgy) and mix it in a mixer; put the mixed raw tantalum powder in a press, and press it into powdered tantalum powder Bar compact; place the powdered tantalum billet in a vacuum of 3.5x10 -3 In the vacuum graphite furnace of Pa, raise the temperature of the vacuum graphite furnace to 1850°C at an increment of 100°C / h, keep it warm for 2.5h, and then cool to room temperature to obtain sintered tantalum bars;

[0080] Put the tantalum sintered strip in the melting furnace for the first electron beam melting. The parameters of the first electron beam melting are: the vacuum degree of the melting furnace is 5x10 -3 Pa, the voltage is 21KV, the current is 6A, the feed rate is 21kg / h, the cooling time is 3.5h, and the tantalum ingot with a diameter of 110mm is obtained by melting;

[0081] Put the tantalum ingot in the melting furnace for the second electron be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com