Particulate ferrous sulfate heptahydrate and its preparing method and device

A technology of ferrous sulfite heptahydrate and ferrous sulfate, which is applied in the direction of ferric sulfate, can solve the problems of easy agglomeration and oxidation of ferrous sulfate heptahydrate, packaging, storage and transportation, and inconvenient use, and achieve equipment design or selection Easy to model, convenient to pack and store, no three wastes to pollute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

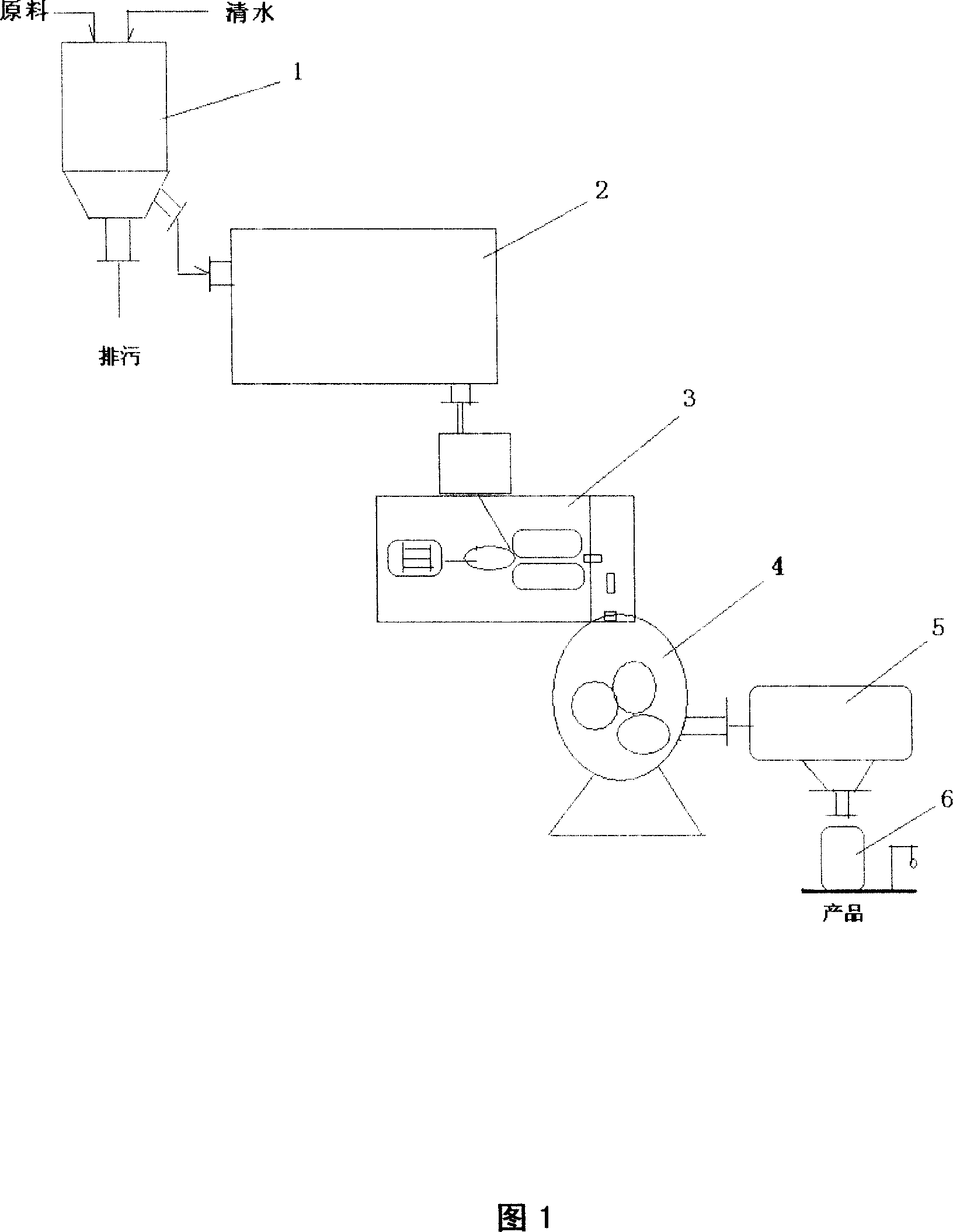

Embodiment 1

[0028] Wash ferric sulfite heptahydrate, a by-product of the titanium dioxide factory, with clear water to remove surface impurities. The ratio of ferric sulfite heptahydrate to clear water is 5-30 kg of water per 100 kg of ferric sulfite heptahydrate. After stirring, place 10- After 20 minutes, remove the floating matter floating on the top, drain the impurities deposited at the bottom, then filter and drain the water to obtain pure ferric sulfite heptahydrate. Part of the ferric sulfite heptahydrate can be recovered by concentrating the filtered water. The above-mentioned cleaned iron sulfite heptahydrate is placed in a boiler hot flue gas drier for indirect heating; the obtained iron content is 17-25% (weight content) and free water-free iron sulfite heptahydrate. Then immediately put it into a tablet machine to press the above-mentioned ferrous sulfite heptahydrate without free water into a sheet with a thickness of 2-10mm, then crush it into granular ferrous sulfate hepta...

Embodiment 2

[0030] The iron sulfite heptahydrate, a by-product of the titanium dioxide factory, is first washed to remove surface impurities with clear water. The ratio of ferric sulfite heptahydrate and clear water is to add 5-30 kg of water per 100 kg of ferric sulfite heptahydrate, and stir for 5-10 minutes. Set it aside for 10-20 minutes, remove the floating matter floating on the top, drain the silt and impurities with a large specific gravity deposited at the bottom, then filter and drain the water to obtain pure ferric sulfite heptahydrate. Part of the ferric sulfite heptahydrate can be recovered by concentrating the filtered water. Put the cleaned ferric sulfite heptahydrate into an airflow drier to dry to obtain ferric sulfite heptahydrate with an iron content of 17-25% (weight content) and no free water. Then immediately press the above-mentioned ferrous sulfite heptahydrate without free water into a sheet with a thickness of 2-10mm with a tablet machine, then crush it into gran...

Embodiment 3

[0032]The iron and steel plant by-product ferric sulfite heptahydrate is first washed with clean water to remove surface impurities, the ratio of ferric sulfite heptahydrate and clear water is 20-30 kg of water per 100 kg of ferric sulfite heptahydrate, and after stirring for 5-10 minutes, clean Place for 10-20 minutes, remove the floating matter floating on the top, drain the silt deposited at the bottom and the impurities with larger specific gravity, then filter, and drain the water to obtain an iron content of 17-25% (weight content) Pure ferric sulfite heptahydrate. Part of the ferric sulfite heptahydrate can be recovered by concentrating the filtered water. The above-mentioned cleaned iron sulfite heptahydrate is placed in a microwave oven and heated by microwave for 3-10 minutes to obtain the iron sulfite heptahydrate without free water. Then press the above-mentioned ferrous sulfite heptahydrate without free water into a sheet with a thickness of 2-10mm with a tablet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com