Method for preparing sintered mixture from municipal sludge and ferrous iron containing metallurgical dust

A municipal sludge and iron and steel metallurgy technology, applied in the direction of process efficiency improvement, etc., can solve problems affecting sintering air permeability, metallurgical dust and sludge secondary pollution, etc., achieve efficient resource recycling, improve air permeability and sinter quality , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

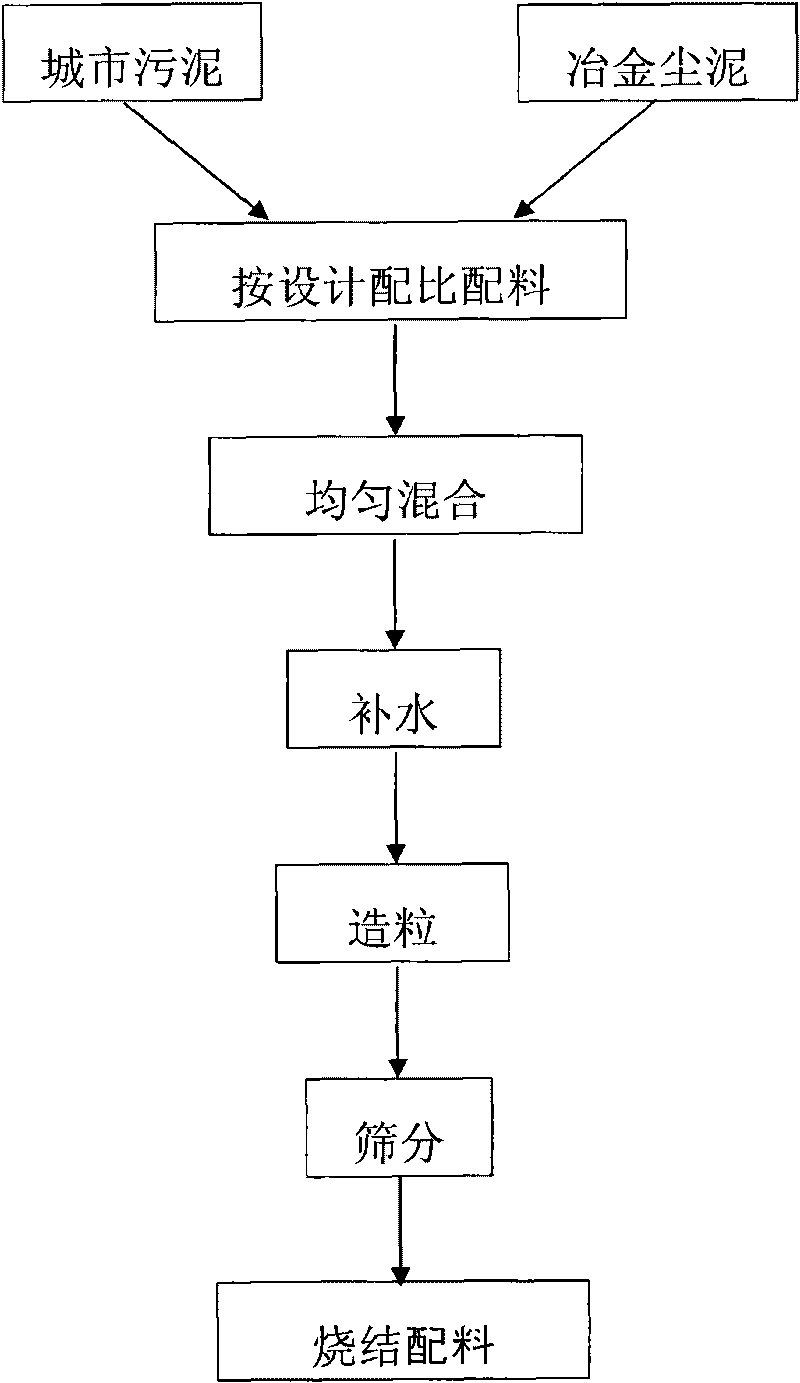

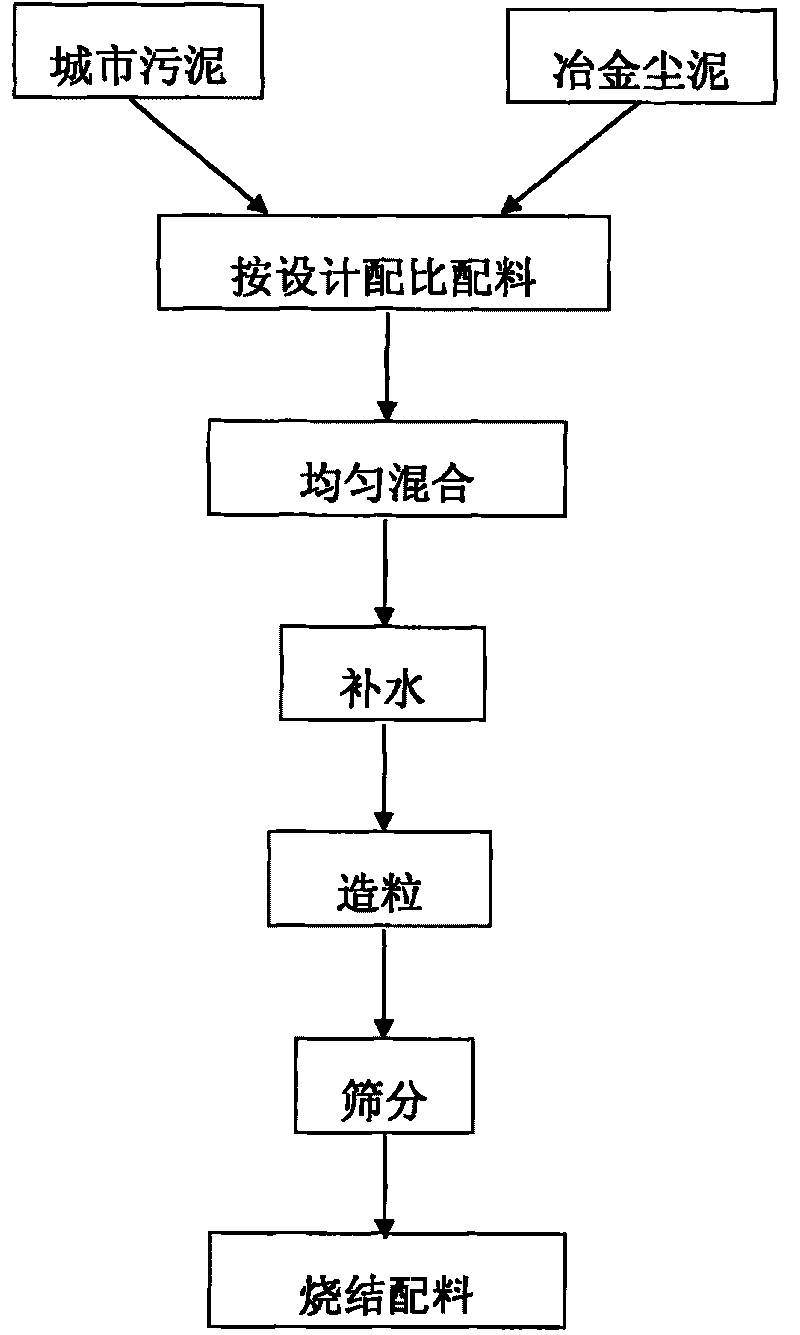

Method used

Image

Examples

Embodiment 1

[0039] In the ratio of raw materials to be prepared for sintering ingredients (calculated as 100%), the main raw materials are municipal sludge and gas ash, and the high-water sludge (lime-calcified sludge, water content: 40%; CaO: 49.2%; SiO 2 : 3.0%), the addition amount is 30%, gas ash (moisture content: 2%; TFe: 22.0%; C: 46.5%; SiO 2 (CaO: 6.4%; CaO: 4.9%) is 70%. The raw materials are mixed uniformly in the mixer, and then 9.6wt% of water is added to the total mass ratio, and then granulated and screened by a vibrating screening device. Produce granulated particles of suitable size (2 : 5.4%; CaO: 9.9%, the 0.5m drop strength and compressive strength of 20 pellets with a particle diameter of 5-10mm are measured, the average value of 0.5m drop strength is 5.8 times, and the average value of compression strength is 19.1N , Has a good use strength.

Embodiment 2

[0041] In the raw material ratio (calculated as 100%) for sintering ingredients preparation, the main raw materials are municipal sludge and gas ash, and the raw materials are dry sludge (lime calcified sludge, water content: 2%; CaO: 49.2%; SiO 2 : 3.0%), the added amount is 24%, gas ash (water content: 2%; TFe: 22.0%; C: 46.5%; SiO 2 (CaO: 6.4%; CaO: 4.9%) is 76%. The raw materials are mixed uniformly in the mixer, and then 19.8wt% of water is added to the total mass ratio, and then granulated, and passed through a vibrating screening device The granulated particles of suitable size (2 :5.5%; CaO: 12.7%, the 0.5m drop strength and compressive strength of 20 pellets with a particle diameter of 5-10mm are measured. The average value of 0.5m drop strength is 6.8 times, and the average value of compressive strength is 22.6N , Has a good use strength.

Embodiment 3

[0043] In the ratio of raw materials to be prepared for sintering ingredients (calculated by 100%), the main raw materials are urban sludge, gas ash and converter OG mud, and the ratio of raw materials is urban sludge (lime-calcified sludge, water content: 40 %; CaO: 49.2%; SiO 2 : 3.0%), the addition amount is 20%, gas ash (water content: 2%; TFe: 22.0%; C: 46.5%; SiO 2 : 6.4%; CaO: 4.9%) the addition amount is 40%, converter OG mud (water content: 20%; TFe: 41.5%; C: 4.4%; SiO 2 :2.4%; CaO: 20.0%) The addition amount is 40%, the raw materials are mixed uniformly in the mixer, and then 8.0wt% of the total mass of water is added to the granulation, and the vibrating screening device The granulated particles of suitable size (2 : 4.4%; CaO: 17.1%, the 0.5m drop strength and compressive strength of 20 pellets with a particle diameter of 5-10mm are measured, the average value of 0.5m drop strength is 8.9 times, and the average value of compressibility is 29.1N , Has a good use stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com