Heat flow balance internal combustion engine waste heat utilization system

A heat flow balance, internal combustion engine technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problem of limited utilization of waste heat and achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

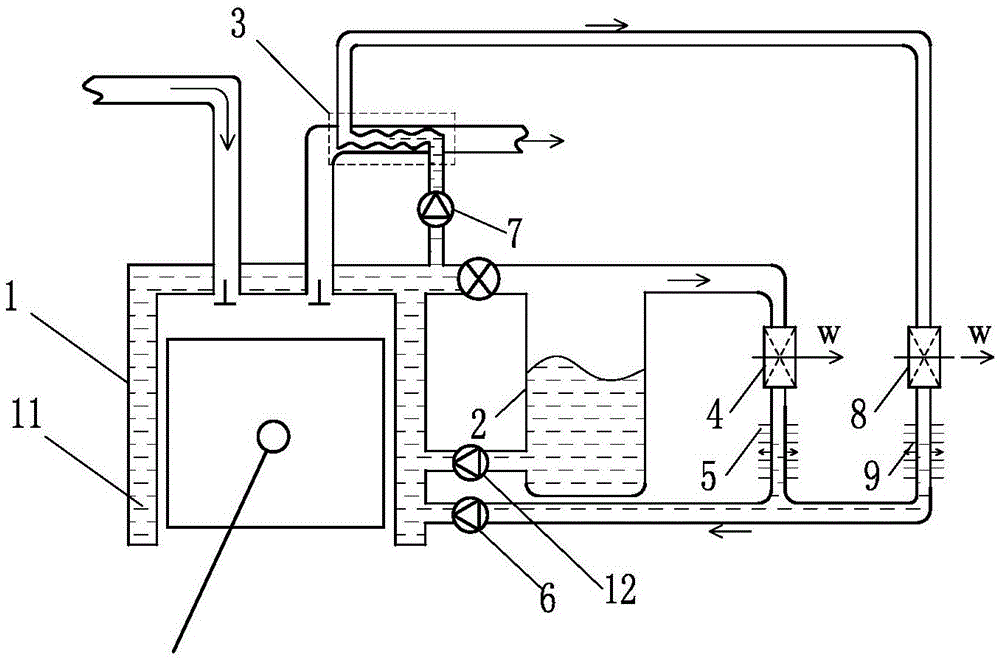

[0050] Such as figure 1 The shown heat flow balance internal combustion engine waste heat utilization system includes an internal combustion engine 1, a gas-liquid separator 2 and an exhaust heat exchanger 3, and the liquid outlet of the gas-liquid separator 2 is connected to the cooling fluid channel of the internal combustion engine 1 through a circulation pump 12 The fluid inlet of the cooling fluid channel 11 is connected, the fluid outlet of the cooling fluid channel 11 is connected with the fluid inlet of the gas-liquid separator 2, and the gas outlet of the gas-liquid separator 2 is connected with the working medium inlet of the cylinder liner steam working mechanism 4 , the working medium outlet of the liner steam working mechanism 4 communicates with the gas inlet of the liner steam condenser 5, and the liquid outlet of the liner steam condenser 5 communicates with the cooling fluid channel 11 through the liner liquid circulation pump 6 The fluid inlet of the cooling...

Embodiment 2

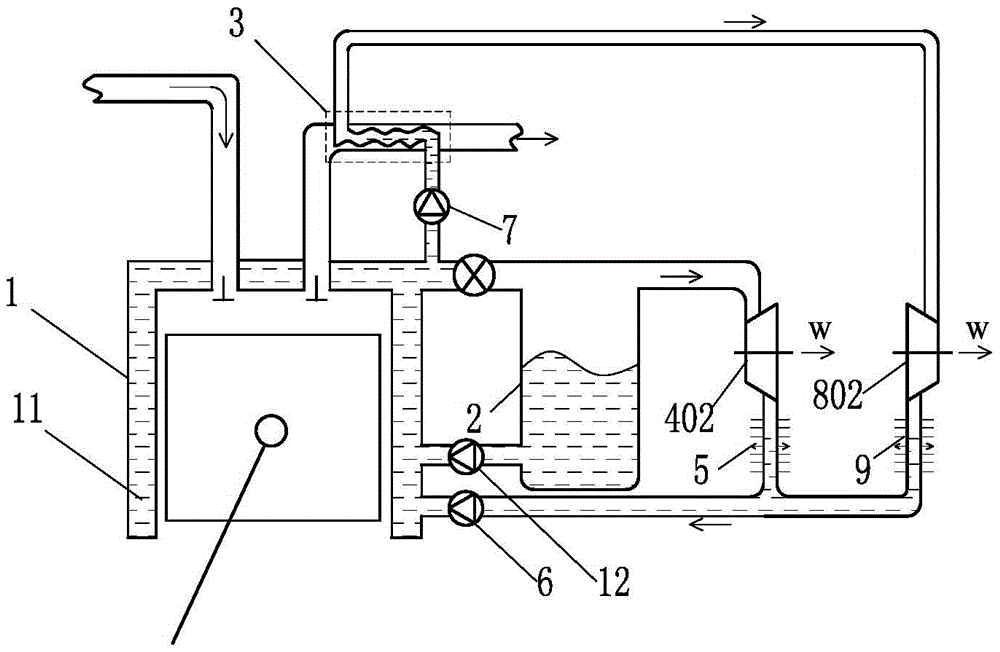

[0052] Such as figure 2 The heat flow balance internal combustion engine waste heat utilization system shown differs from Embodiment 1 in that: the cylinder liner steam work mechanism 4 is set as an impeller-type work mechanism 402, and the exhaust steam work mechanism 8 is set as an impeller-type work mechanism Mechanism 802, specifically, both the impeller-type work mechanism 402 and the impeller-type work mechanism 802 can be set as radial flow turbines.

[0053] Optionally, both the impeller type working mechanism 402 and the impeller type working mechanism 802 are set as axial flow turbines or one of them is set as a radial flow turbine and the other is set as an axial flow turbine.

Embodiment 3

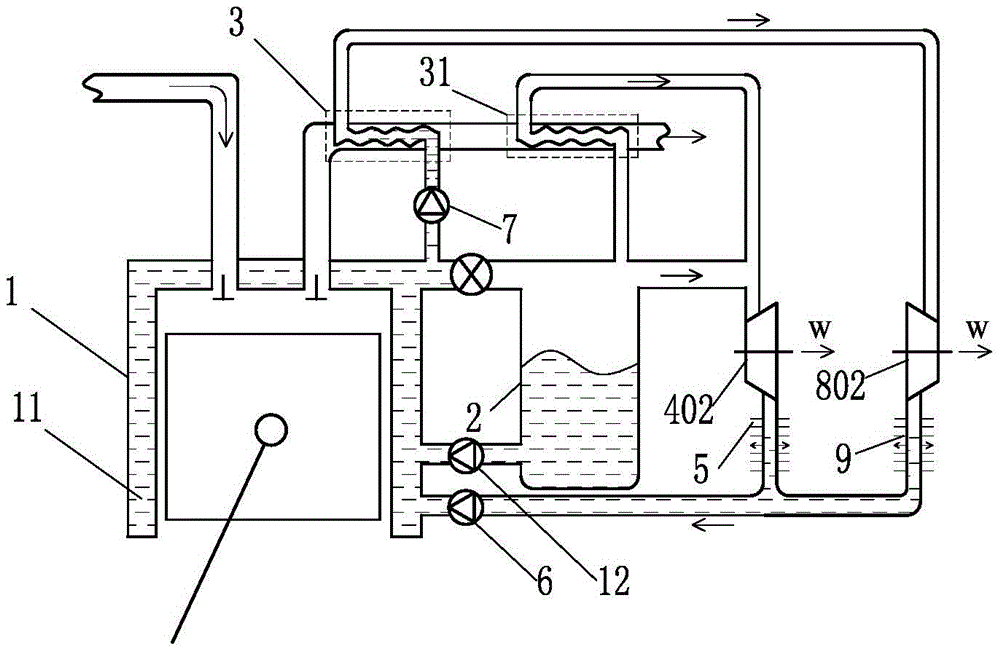

[0055] Such as image 3 The heat flow balance internal combustion engine waste heat utilization system shown differs from Embodiment 2 in that: the heat flow balance internal combustion engine waste heat utilization system also includes an auxiliary exhaust heat exchanger 31, and the gas outlet of the gas-liquid separator 2 passes through the The heated fluid channel of the auxiliary exhaust heat exchanger 31 communicates with the working medium inlet of the cylinder liner steam working mechanism 4 .

[0056] Optionally, the cylinder liner steam working mechanism 4 is changed to the cylinder liner nozzle propelling rotor working mechanism 401 , and the exhaust steam working mechanism 8 is changed to the exhaust nozzle propelling rotor working mechanism 801 .

[0057] Optionally, the cylinder liner steam work mechanism 4 is changed to the cylinder liner nozzle propulsion rotor work mechanism 401, and the exhaust steam work mechanism 8 is changed to the exhaust nozzle propulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com