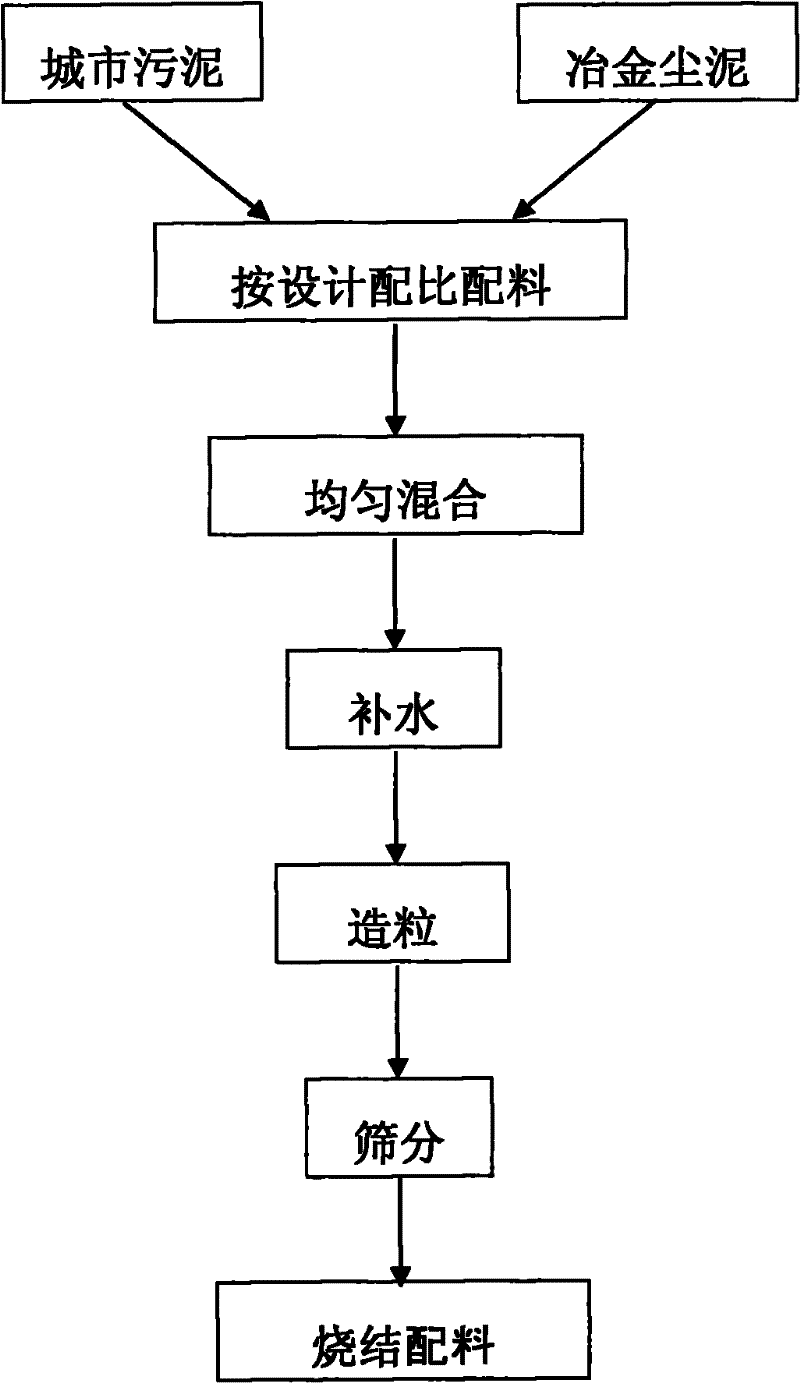

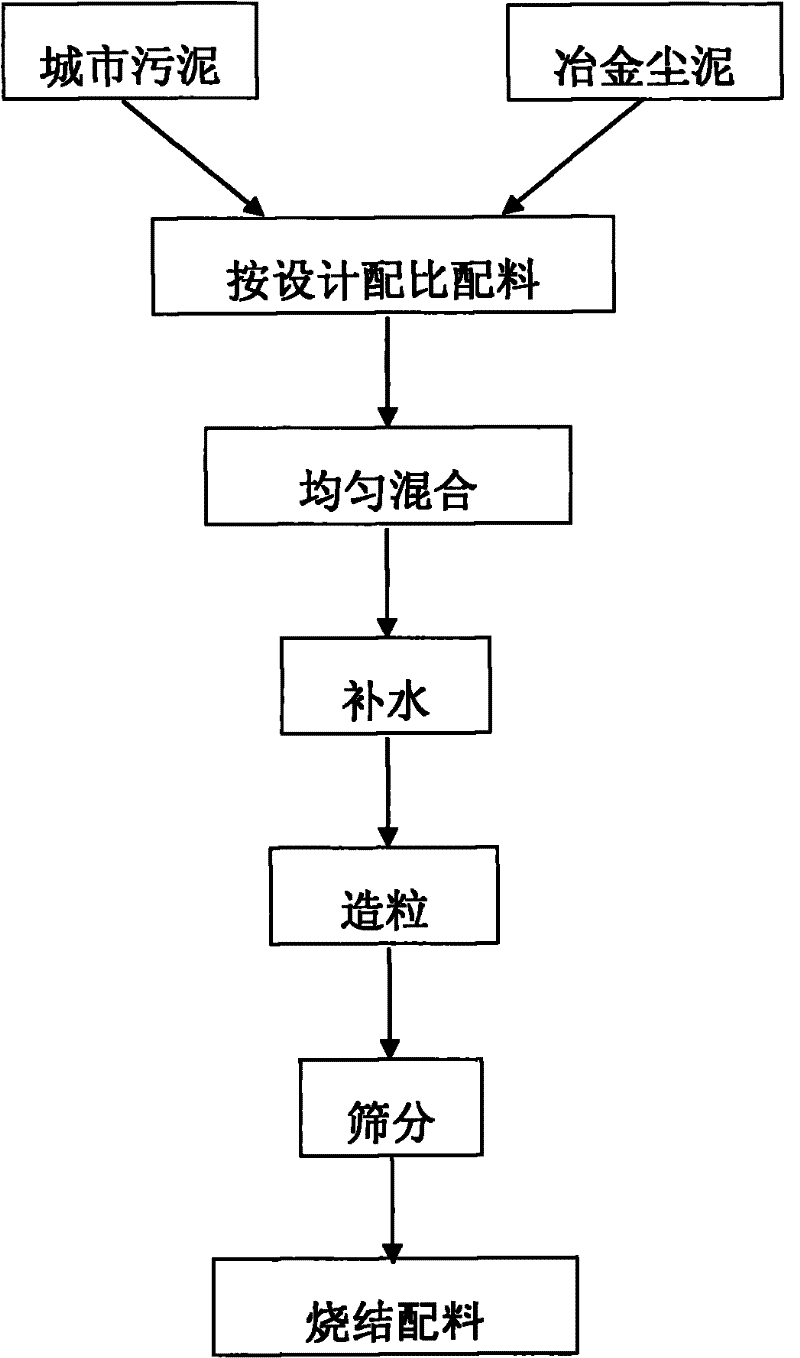

Method for preparing sintered mixture from municipal sludge and ferrous iron containing metallurgical dust

A technology for iron and steel metallurgy and urban sludge, applied in the direction of improving process efficiency, can solve the problems of secondary pollution of metallurgical dust and sludge, affecting the permeability of sintering, etc., to achieve environmental protection, efficient recycling of resources, and uniform composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the raw material ratio (calculated by 100%) to be prepared for sintering batching, municipal sludge and gas ash are used as main raw materials, and high water content sludge (lime calcified sludge, water content: 40%; CaO: 49.2%; SiO 2 : 3.0%) was added in an amount of 30%, gas ash (water content: 2%; TFe: 22.0%; C: 46.5%; SiO 2 : 6.4%; CaO: 4.9%) is added in an amount of 70%. The raw materials are mixed evenly in the mixer, and then granulated after adding water accounting for 9.6wt% of the total mass ratio, and screened by a vibrating sieving device The granulated particles of suitable size (2 : 5.4%; CaO: 9.9%. The 0.5m drop strength and compressive strength were measured for 20 pellets with a particle size of 5-10mm. The average value of the 0.5m drop strength was 5.8 times, and the average compressive strength was 19.1N , with better use strength.

Embodiment 2

[0041] In the raw material ratio (calculated by 100%) to be prepared by sintering ingredients, municipal sludge and gas ash are used as main raw materials, and dry sludge (lime calcified sludge, water content: 2%; CaO: 49.2%; SiO 2 : 3.0%) was added in an amount of 24%, gas ash (moisture content: 2%; TFe: 22.0%; C: 46.5%; SiO 2 : 6.4%; CaO: 4.9%) was added in an amount of 76%, the raw materials were mixed evenly in the mixer, and then granulated after adding water accounting for 19.8wt% of the total mass ratio, and passed through a vibrating screening device The granulated particles with suitable size (2 : 5.5%; CaO: 12.7%. The 0.5m drop strength and compressive strength were measured for 20 pellets with a particle size of 5-10mm. The average value of the 0.5m drop strength was 6.8 times, and the average value of the compressive strength was 22.6N , with better use strength.

Embodiment 3

[0043] In the raw material ratio (100%) to be prepared by sintering batching, municipal sludge, gas ash and converter OG mud are the main raw materials, and urban sludge (lime calcified sludge, water content: 40% %; CaO: 49.2%; SiO 2 : 3.0%) was added in an amount of 20%, gas ash (moisture content: 2%; TFe: 22.0%; C: 46.5%; SiO 2 : 6.4%; CaO: 4.9%) was added in an amount of 40%, converter OG mud (moisture content: 20%; TFe: 41.5%; C: 4.4%; SiO 2 : 2.4%; CaO: 20.0%) is added in an amount of 40%, the raw materials are mixed evenly in the mixer, and then granulated after adding water accounting for 8.0wt% of the total mass ratio, through a vibrating screening device The granulated particles with suitable size (2 : 4.4%; CaO: 17.1%. The 0.5m drop strength and compressive strength were measured for 20 pellets with a particle size of 5-10mm. The average value of the 0.5m drop strength was 8.9 times, and the average value of the compressive strength was 29.1N , with better use stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com