Austenite alloy EBSD sample preparation method

An austenite and alloy technology, applied in the field of electron microscope sample preparation, can solve the problems of high energy consumption of low-temperature polishing, environmental pollution by electrolyte, complicated preparation process, etc., and achieve the effect of shortening preparation time, reducing preparation links and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

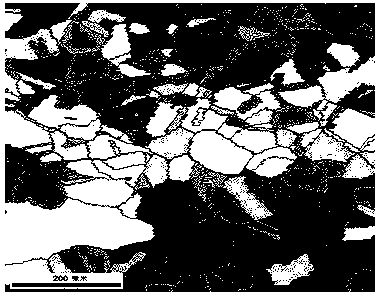

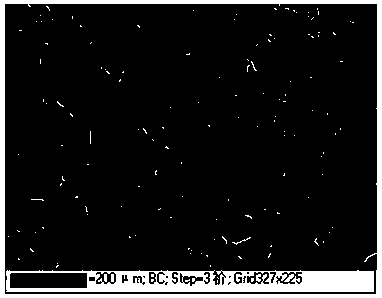

[0021] The preparation method of the austenitic alloy EBSD sample in this embodiment includes austenitic alloy sample preparation, grinding, polishing, fine polishing, two-step ultrasonic treatment and drying process. The specific process steps are as follows:

[0022] (1) Sample preparation process: 316L austenitic stainless steel samples are prepared by wire electric discharge cutting;

[0023] (2) Grinding process: During the grinding process, 150-mesh, 400-mesh, 1000-mesh and 2000-mesh silicon carbide water abrasive paper is used to polish the sample four times, and the speed of the metallographic grinding and polishing machine is 300 rpm;

[0024] (3) Polishing process: during the polishing process, diamond polishing paste with a particle size of 2.5 μm, 1.5 μm and 0.5 μm is used to polish the sample three times, and the speed of the metallographic polishing machine is 400 rpm;

[0025] (4) Fine polishing process: After grinding and polishing, wash the surface with water,...

Embodiment 2

[0030] The preparation method of the austenitic alloy EBSD sample in this embodiment includes austenitic alloy sample preparation, grinding, polishing, fine polishing, two-step ultrasonic treatment and drying process. The specific process steps are as follows:

[0031] (1) Sample preparation process: Inconel 600 austenitic stainless steel samples are prepared by wire electric discharge cutting;

[0032] (2) Grinding process: During the grinding process, 80-mesh, 600-mesh, 800-mesh and 3000-mesh silicon carbide water abrasive paper was used to polish the sample four times, and the speed of the metallographic grinding and polishing machine was 400 rpm;

[0033] (3) Polishing process: During the polishing process, diamond polishing paste with a particle size of 3.5 μm, 1.0 μm and 0.5 μm is used to polish the sample for three times, and the speed of the metallographic polishing machine is 400 rpm;

[0034] (4) Fine polishing process: After grinding and polishing, wash the surface ...

Embodiment 3

[0039] The preparation method of the austenitic alloy EBSD sample in this embodiment includes austenitic alloy sample preparation, grinding, polishing, fine polishing, two-step ultrasonic treatment and drying process. The specific process steps are as follows:

[0040] (1) Sample preparation process: 304 austenitic stainless steel samples are prepared by WEDM;

[0041] (2) Grinding process: During the grinding process, 80-mesh, 400-mesh, 800-mesh and 2000-mesh silicon carbide water abrasive paper was used to polish the sample four times, and the speed of the metallographic grinding and polishing machine was 375 rpm;

[0042] (3) Polishing process: during the polishing process, diamond polishing paste with a particle size of 3.5 μm, 1.5 μm and 0.5 μm is used to polish the sample three times, and the speed of the metallographic polishing machine is 300 rpm;

[0043] (4) Fine polishing process: wash the surface with water after grinding and polishing, and then carry out the fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com