High-strength casting titanium alloy and preparation method thereof

A casting titanium alloy, high-strength technology, applied in the field of titanium alloy material manufacturing, can solve problems such as lack and harshness, achieve the effects of inhibiting the deterioration of alloy high-temperature performance, good casting performance, and improving solid solution strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of above-mentioned alloy material, comprises the following steps:

[0032] 1) Compound titanium sponge, aluminum beans, aluminum-molybdenum alloy, niobium-titanium alloy, zirconium sponge, titanium-tin alloy, and metal chromium according to the component content, and use a press and mold to press the raw materials into a strip-shaped electrode block;

[0033] 2) Vacuum plasma welding, argon shielded plasma welding or vacuum electron beam welding is used to weld the pressed electrode blocks into long strip electrodes;

[0034] 3) Using the strip electrode prepared in step 2) as a consumable electrode for melting in a vacuum consumable electric arc furnace to obtain a primary ingot, the melting voltage is 26-32V, and the melting current is 8-10KA;

[0035] 4) Invert the primary ingot and use it as a consumable electrode for secondary melting in a vacuum consumable electric arc furnace to obtain a secondary ingot. The melting voltage is 28-36V and th...

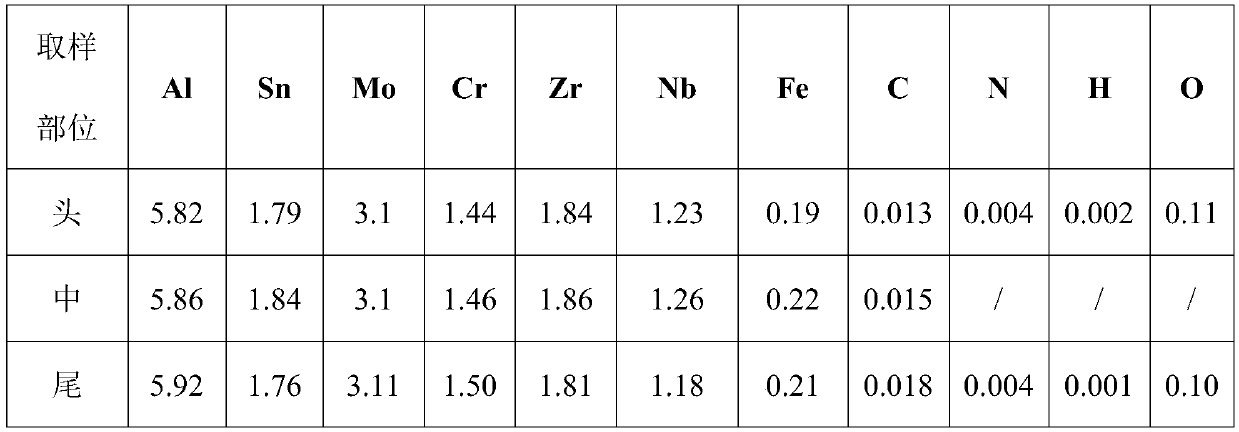

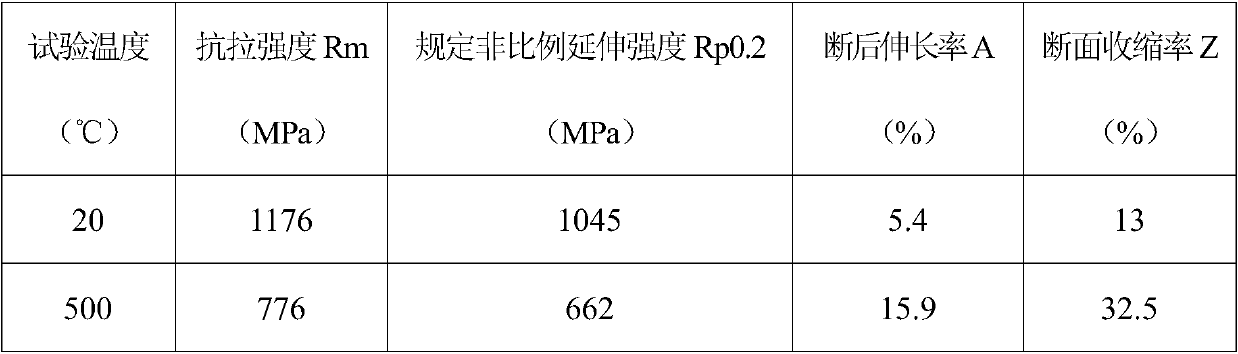

Embodiment 1

[0048] Taking the preparation of Ti-6.0Al-1.8Sn-1.8Zr-3.0Mo-1.5Cr-1.2Nb-0.2Fe titanium alloy casting as an example

[0049] 1) Compound titanium sponge, aluminum beans, aluminum-molybdenum alloy, niobium-titanium alloy, zirconium sponge, titanium-tin alloy, and metal chromium according to the component content, and use a press and a mold to press the raw materials into a strip-shaped electrode block.

[0050] 2) Vacuum plasma welding, argon shielded plasma welding or vacuum electron beam welding is used to weld the pressed electrode blocks into long strip electrodes;

[0051] 3) using the strip electrode prepared in step 2) as a consumable electrode to melt in a vacuum consumable electric arc furnace to obtain a primary ingot, the melting voltage is 26V, and the melting current is 8KA;

[0052] 4) Invert the primary ingot and use it as a consumable electrode for secondary melting in a vacuum consumable electric arc furnace to obtain a secondary ingot. The melting voltage is 28...

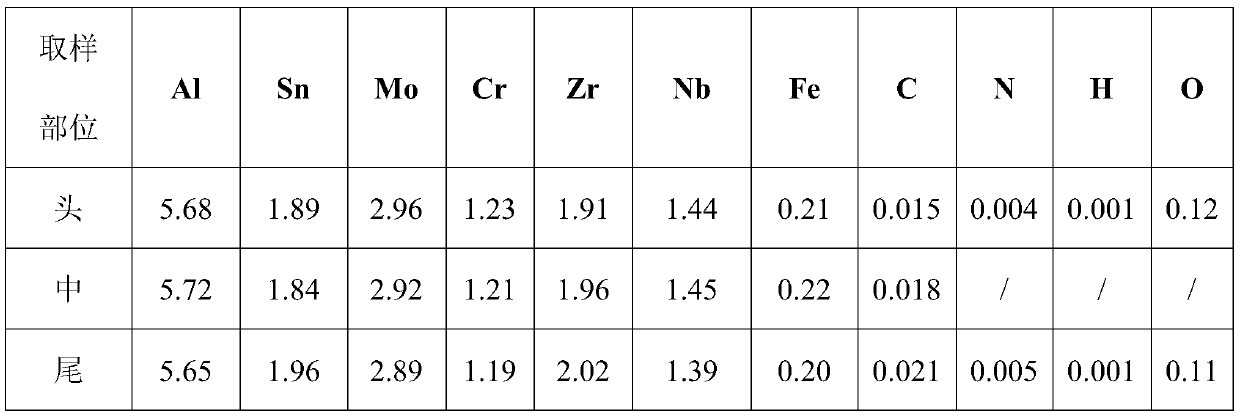

Embodiment 2

[0069] Taking the preparation of Ti-5.8Al-2.0Sn-2.0Zr-2.8Mo-1.2Cr-1.4Nb-0.20Fe titanium alloy casting as an example

[0070] 1) Compound titanium sponge, aluminum beans, aluminum-molybdenum alloy, niobium-titanium alloy, zirconium sponge, titanium-tin alloy, and metal chromium according to the component content, and use a press and a mold to press the raw materials into a strip-shaped electrode block.

[0071] 2) Vacuum plasma welding, argon shielded plasma welding or vacuum electron beam welding is used to weld the pressed electrode blocks into long strip electrodes;

[0072] 3) using the strip electrode prepared in step 2) as a consumable electrode to melt in a vacuum consumable electric arc furnace to obtain a primary ingot, the melting voltage is 27V, and the melting current is 9KA;

[0073] 4) Invert the primary ingot and use it as a consumable electrode for secondary melting in a vacuum consumable electric arc furnace to obtain a secondary ingot with a melting voltage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com