Economic type core rod alloy steel and preparation and heat treatment method thereof

An alloy steel and economical technology, which is applied in the field of alloy steel for economical mandrel rods and its preparation and heat treatment, can solve the problems of prolonging the production cycle, affecting the production of continuous rolling steel pipes, and insufficient toughness, so as to improve the strength, toughness and thermal stability properties, improve solid solution strengthening, and improve the effect of liquefied carbides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

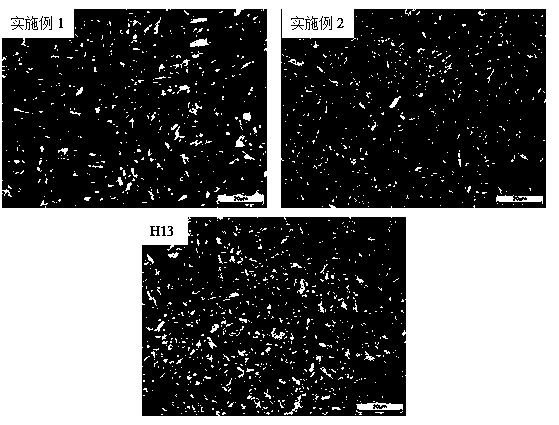

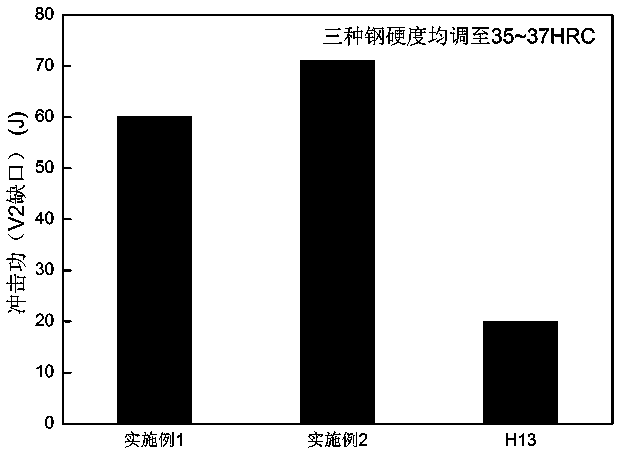

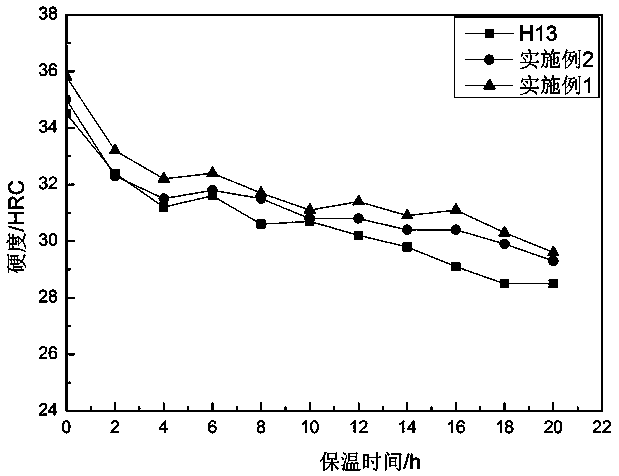

Embodiment 1

[0032] In this embodiment, the composition and mass percentages of the alloy steel for the economical mandrel are as follows:

[0033] C 0.30%

[0034] Si 0.20%

[0035] Mn 1.52%

[0036] Cr 3.60%

[0037] Mo 0.28%

[0038] V 0.36%

[0039] Nb 0.048%

[0040] P 0.012%

[0041] S 0.005%

[0042] Fe balance

[0043] The preparation and heat treatment method in the present embodiment are as follows:

[0044] a. Electric furnace smelting: Melting in an electric arc furnace according to the ratio of alloying elements in Example 1, the melting temperature is greater than 1500°C, casting into a Ф740mm electrode rod, and annealing at 860°C for 20 hours before use;

[0045] b. Electroslag remelting: place the poured electrode rod as a consumable electrode in the electroslag remelting device for electroslag remelting. The slag melting voltage is 52V, the current is 4000A, the electric system voltage is 54V, and the current is 11000A. Capped voltage 60V; current time 40min, ele...

Embodiment 2

[0051] In this embodiment, the composition and mass percentages of the alloy steel for the economical mandrel are as follows:

[0052] C 0.28%

[0053] Si 0.18%

[0054] Mn 1.58%

[0055] Cr 3.92%

[0056] Mo 0.28%

[0057] V 0.37%

[0058] Nb 0.040%

[0059] P 0.013%

[0060] S 0.005%

[0061] Fe balance

[0062] The preparation and heat treatment method in the present embodiment are as follows:

[0063] a. Electric furnace smelting: smelting in an electric arc furnace according to the ratio of alloying elements in Example 2, the melting temperature is greater than 1500°C, casting into a Ф680mm electrode rod, and annealing at 850°C for 18 hours before use;

[0064] b. Electroslag remelting: Place the poured electrode rod as a consumable electrode in the electroslag remelting device for electroslag remelting. The slag melting voltage is 54V, the current is 4200A, the electric system voltage is 56V, the current is 12000A, and the capping voltage 62V; current time 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com