Supercritical extraction separation kettle, extraction system and extraction method

A supercritical and separation kettle technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of reduced flow stability, large cycle space occupation, cumbersome disassembly process, etc., to reduce construction costs and save occupation The effect of improving ground space and extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings.

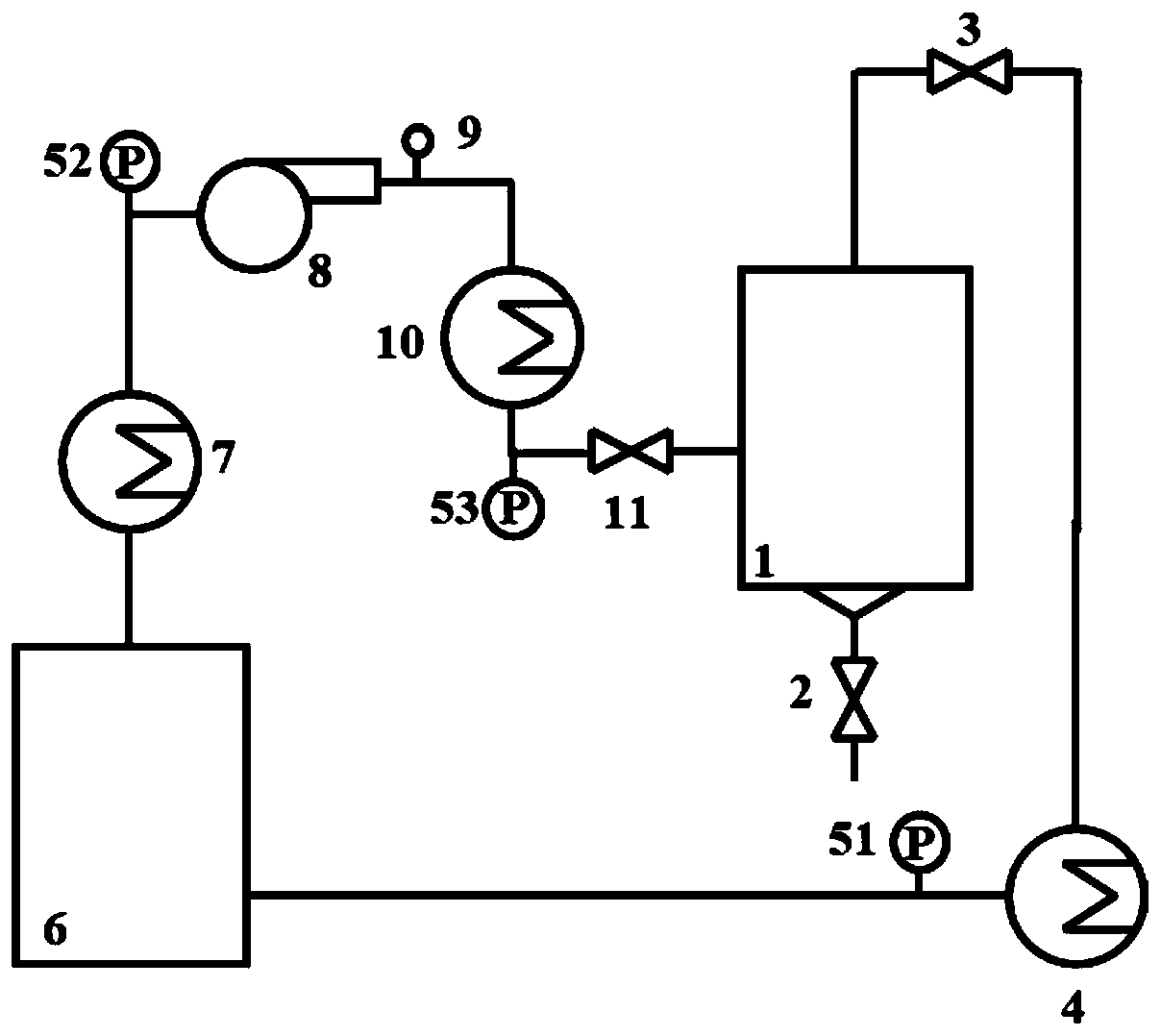

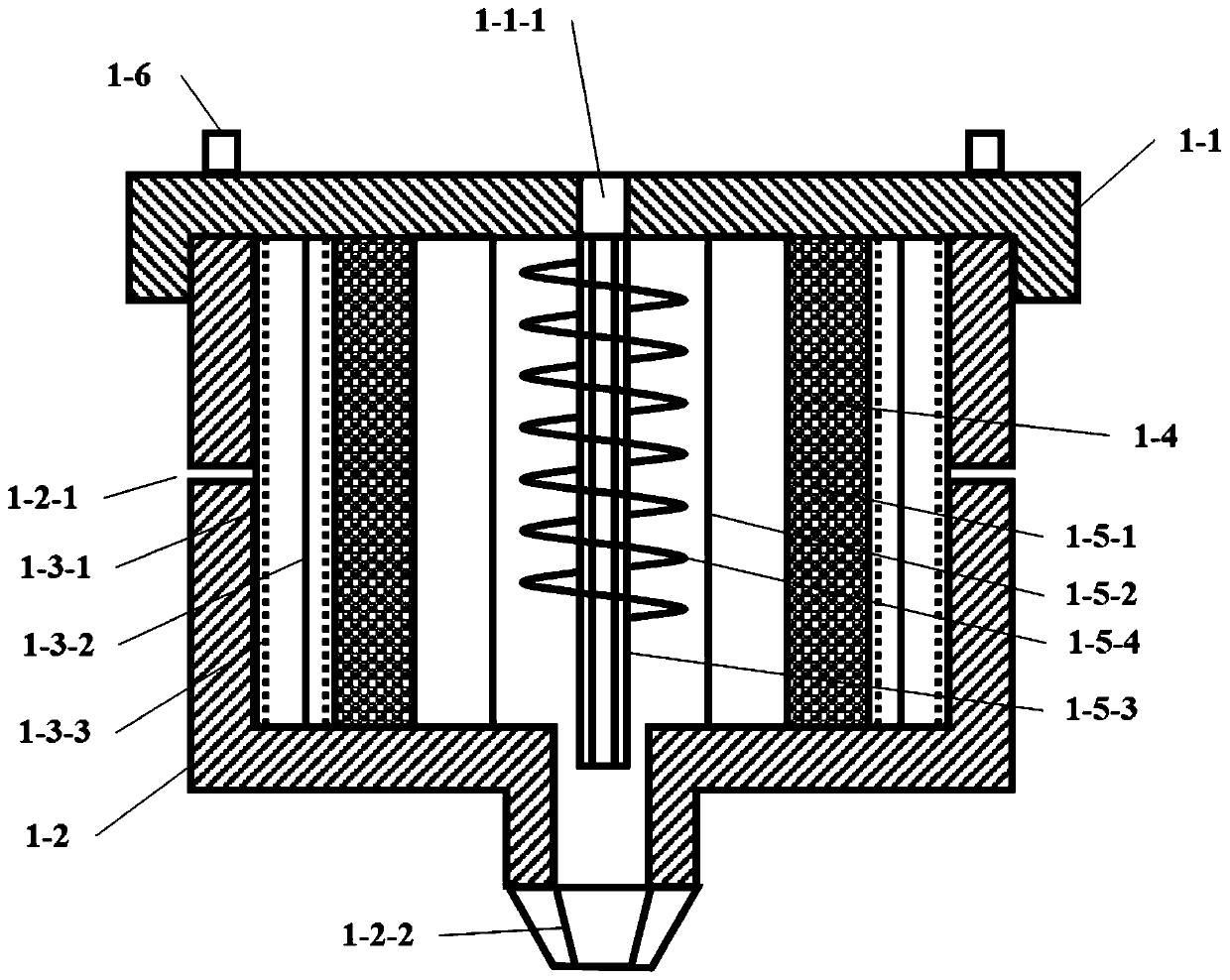

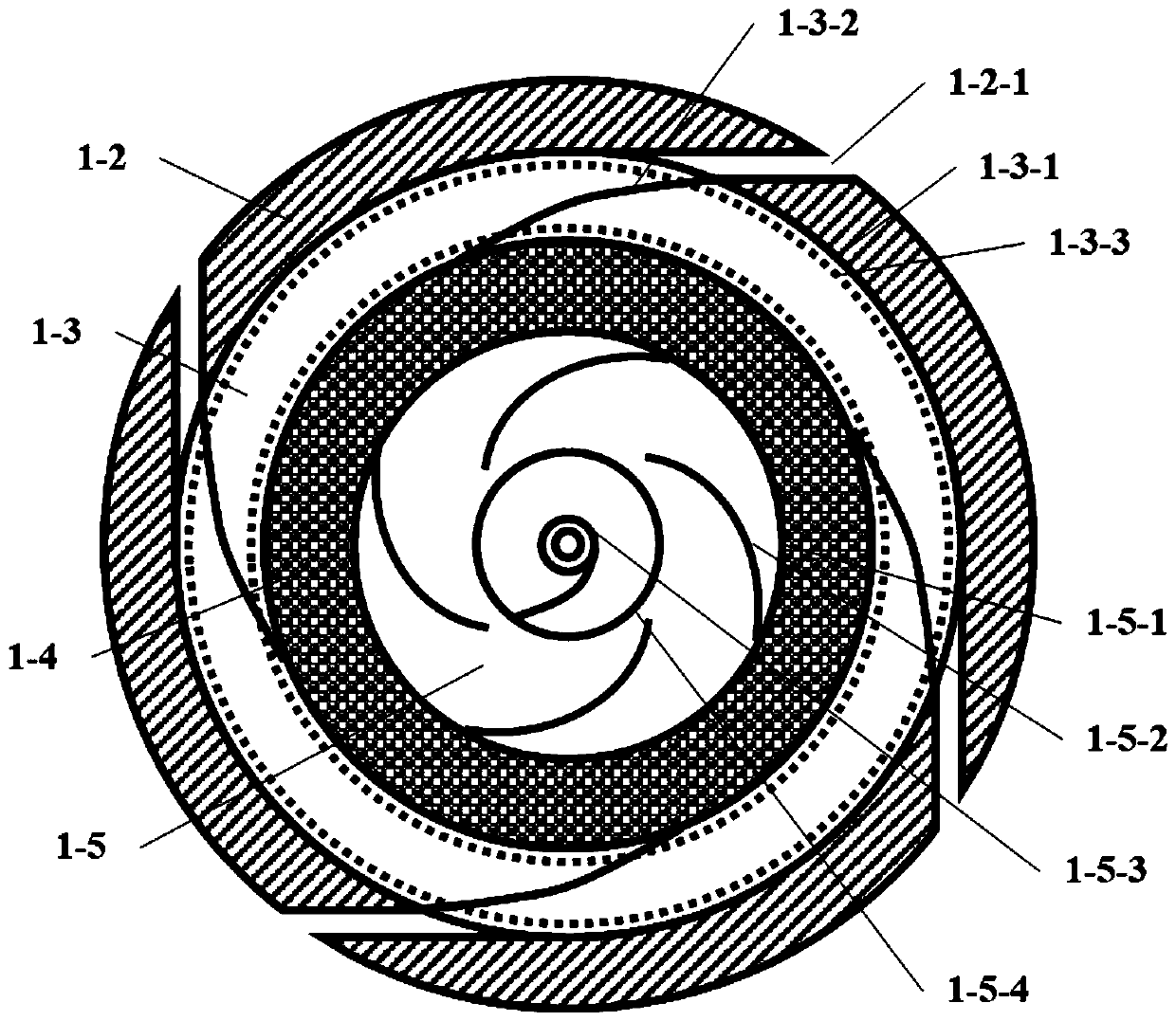

[0034] like figure 1 As shown, the supercritical carbon dioxide circulation extraction system includes: an extraction separation tank 1 , a cooler 4 , a supply tank 6 , a heater 7 , an infusion pump 8 , and a precooler 10 . The carbon dioxide liquid stored in the supply tank 6 is output to the heater 7, and heated to the temperature and pressure (50°C, 10-11MPa) required for extraction through the heater 7 to obtain a supercritical carbon dioxide fluid; The critical carbon dioxide fluid enters the precooler 10 for precooling, and the state of the supercritical carbon dioxide fluid at the outlet of the precooler 10 is controlled to be 43.5-45.2°C and 10.0-10.5MPa; the supercritical carbon dioxide fluid is provided with a third throttle valve The pipeline of 11 enters from the side of the extraction and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com