Device and method for preparing acetoxime

A technology of acetone oxime and heating device, which is applied in oxime preparation, chemical instruments and methods, chemical recovery, etc., can solve the problems of difficult separation and recovery of catalysts, achieve good application value, reduce wear and loss, and shorten the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

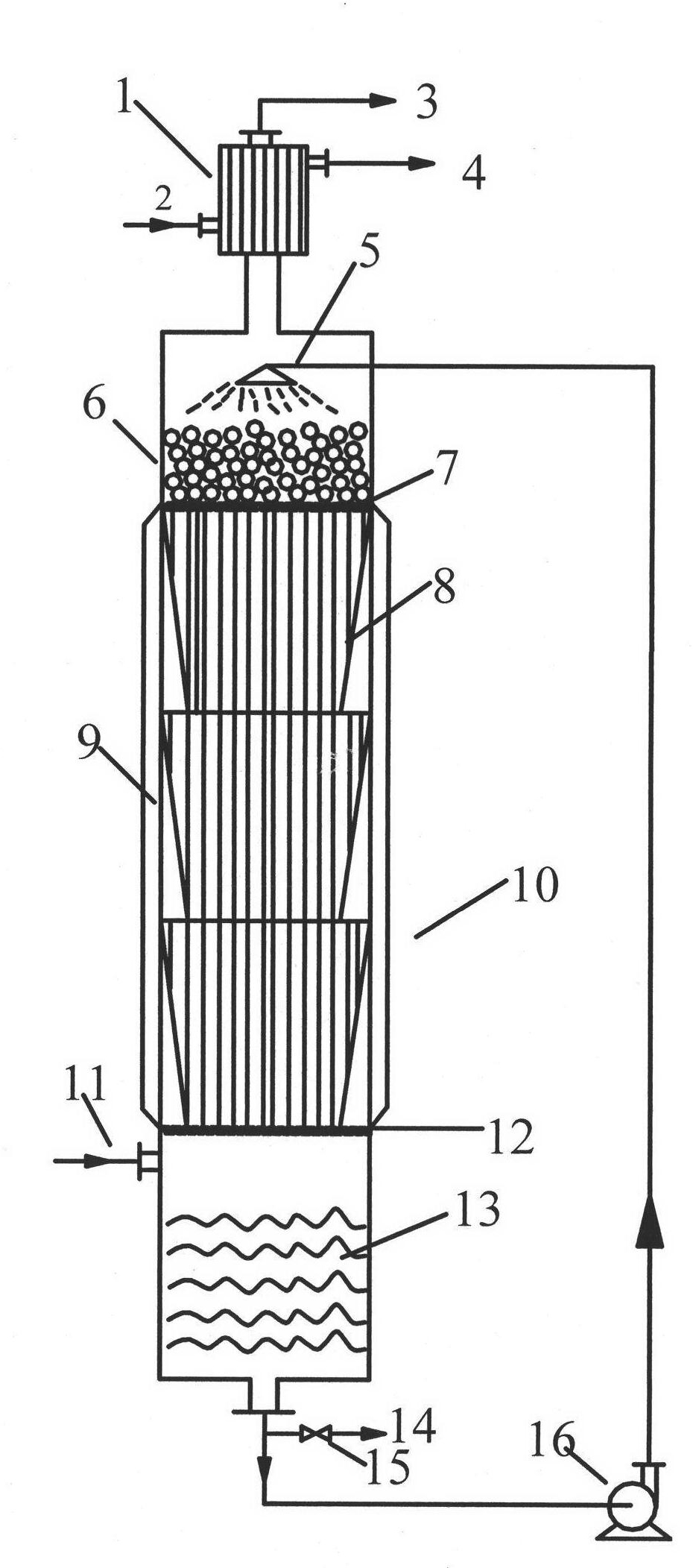

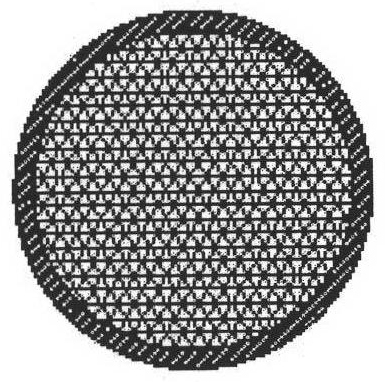

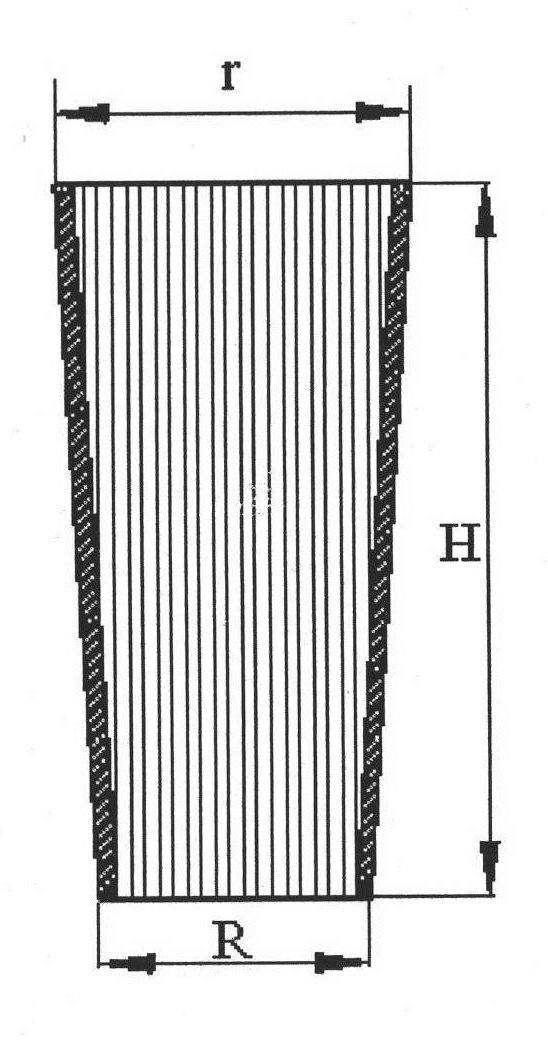

[0040] in such as figure 1 Acetone oxime is prepared in the device, and three monolithic TS-1 catalysts are vertically stacked in the reaction section 8 of the monolithic reactor 10; the characteristic of the cordierite carrier is that the upper bottom radius r: the lower bottom radius R: the height H is 1.5:1 : 2.5; the coating amount of its active component TS-1 molecular sieve of each monolithic TS-1 catalyst is 12% of the carrier mass; the molar ratio of acetone, tert-butanol, water, ammonia and hydrogen peroxide is 1: 1.5 :5:2:1.2; liquid space velocity is 0.5h -1 ; The reaction temperature is 70 ° C; the reaction time is 2h. The conversion of acetone was 89%, and the selectivity of acetone oxime was 79%.

Embodiment 2

[0042] in such as figure 1 Acetone oxime is prepared in the device, and four monolithic TS-1 catalysts are vertically stacked in the reaction section 8 of the monolithic reactor 10; the characteristic of the cordierite carrier is that the upper bottom radius r: the lower bottom radius R: the height H is 1.5:1 : 2.0; the coating amount of its active component TS-1 molecular sieve of each monolithic TS-1 catalyst is 12% of the carrier mass; the molar ratio of acetone, tert-butanol, water, ammonia and hydrogen peroxide is 1: 1.5 :5:2:1.2; liquid space velocity is 0.5h -1 ; The reaction temperature is 70 ° C; the reaction time is 2h. The conversion of acetone was 92%, and the selectivity of acetone oxime was 85%.

Embodiment 3

[0044] in such as figure 1 Acetone oxime is prepared in the device, and four monolithic TS-1 catalysts are vertically stacked in the reaction section 8 of the monolithic reactor 10; the characteristic of the cordierite carrier is that the upper bottom radius r: the lower bottom radius R: the height H is 1.5:1 : 2.0; the coating amount of its active component TS-1 molecular sieve of each monolithic TS-1 catalyst is 10% of the carrier mass; the molar ratio of acetone, tert-butanol, water, ammonia and hydrogen peroxide is 1:2 : 3: 2.4: 1.5; liquid space velocity is 0.5h -1 ; The reaction temperature is 70 ° C; the reaction time is 2h. The conversion of acetone is 90%, and the selectivity of acetone oxime is 82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com