Wastewater ammonia nitrogen blow-off treatment reaction device

A technology of ammonia nitrogen blow-off and reaction device, which is applied in the direction of degassed water/sewage treatment, etc., can solve the problems of affecting the blow-off effect, excessive gas and liquid, channel flow and wall flow, etc., so as to prevent the phenomenon of channel wall flow and improve stability The effect of avoiding waste of gas and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

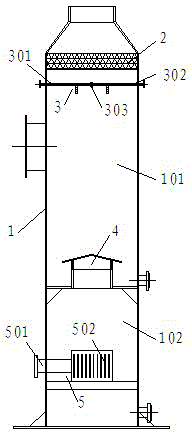

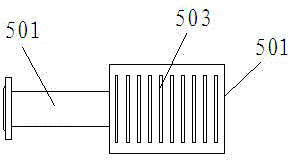

[0021] Embodiment 1: as figure 1 , figure 2 The shown wastewater ammonia nitrogen blow-off treatment reaction device includes a shell 1, and the shell 1 is sequentially arranged with a gas-water separation layer 2, a water distribution device 3, an umbrella-shaped waterproof cover 4, and an air distribution device. 5. The umbrella-shaped waterproof cover 4 divides the shell 1 into upper and lower chambers (101, 102). The upper chamber 101 is provided with a drain pipe 6 on the bottom shell 1. The water distribution device 3 is composed of a water inlet pipe 301 and an air inlet pipe. 302, two-fluid nozzle 303, the water inlet pipe 301 is connected with the air inlet pipe 302, and the two-fluid nozzle 303 facing downward is arranged at the connection to form a three-way structure, the three-way structure is straight tubular, and the two sides are respectively The water pipe 301, the air inlet pipe 302, and the two-fluid nozzle 303 are arranged at the junction of the water inl...

Embodiment 2

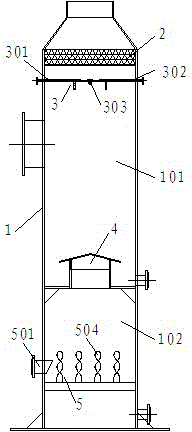

[0022] Embodiment 2: With reference to Embodiment 1, a kind of waste water ammonia nitrogen blow-off treatment reaction device, described air distribution device 5 is arranged on the air inlet pipe 501 on the side wall of the lower chamber 102 shell, and is arranged right against the air inlet pipe 501 Composed of several evenly arranged sheet-like spiral cylinders 504, the number of sheet-like spiral cylinders is 24-32 pieces / m 2 .

[0023] The ammonia nitrogen stripping treatment reaction device for wastewater of the present invention can adopt single-stage or multi-stage serial arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com