Packing tower for industrial waste gas treatment

A technology of industrial waste gas and packed towers, applied in the field of packed towers, can solve problems such as easy wall flow, liquid pollution environment, insufficient energy saving and environmental protection, etc., to achieve the effect of avoiding liquid fluctuations, avoiding environmental pollution, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

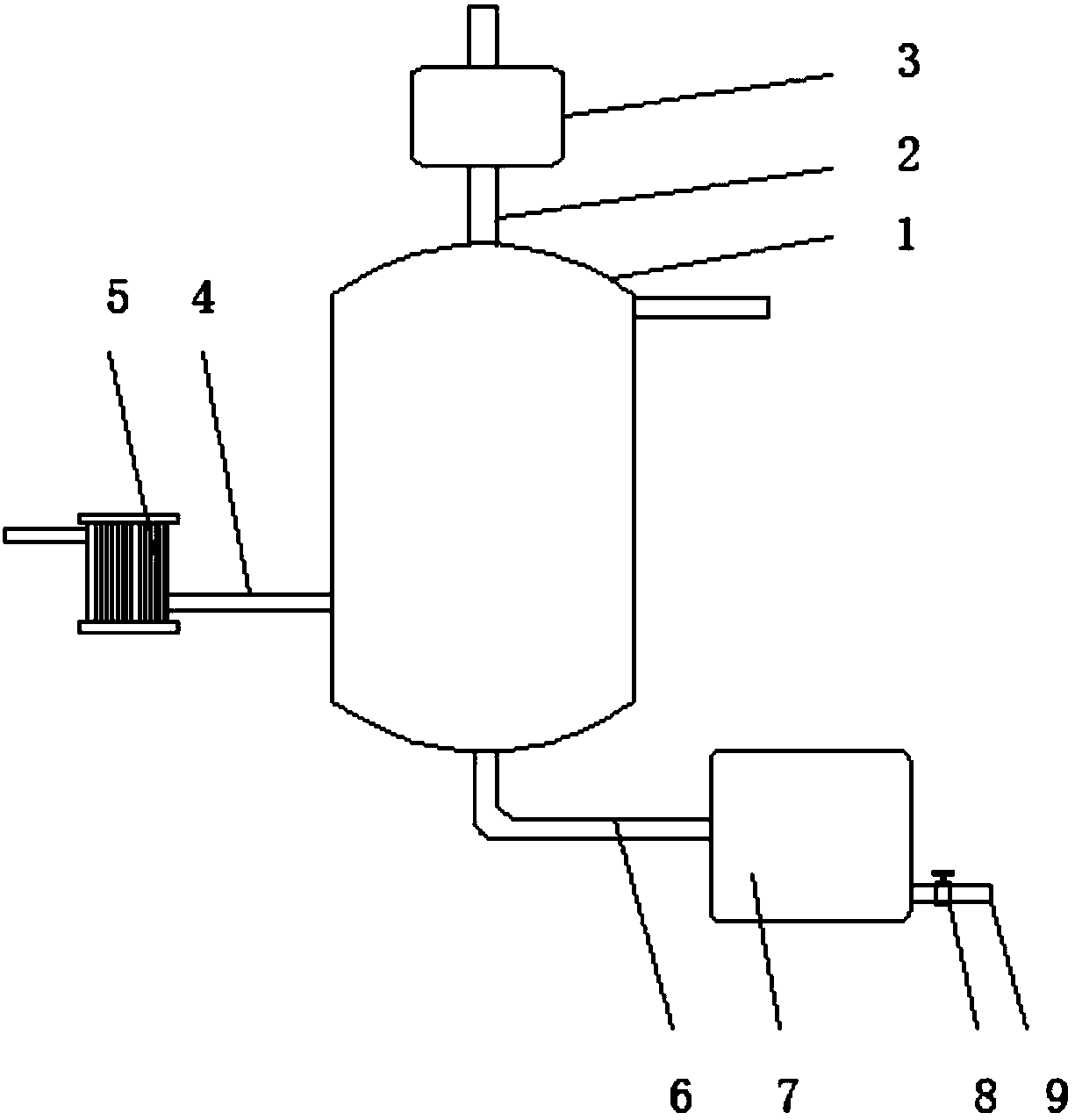

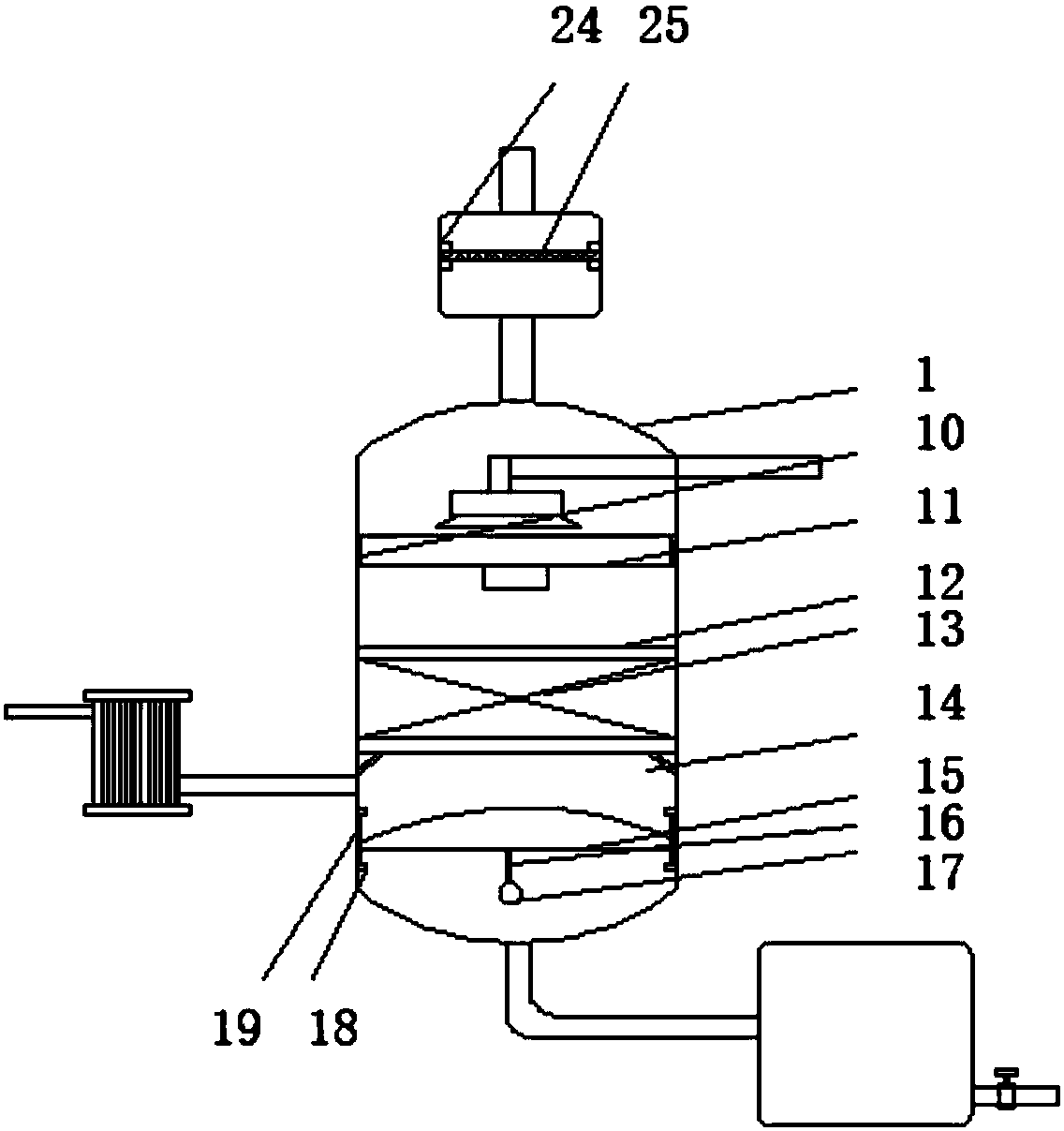

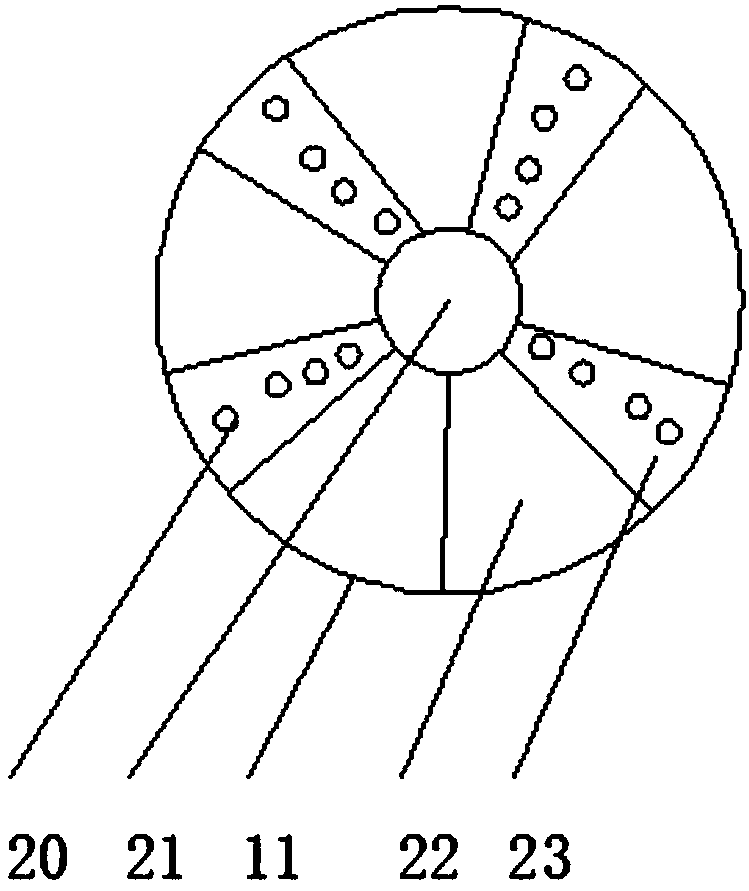

[0018] Such as Figure 1-3 As shown, a packed tower for industrial waste gas treatment includes a packed tower 1, an inlet pipe 4 is welded on one side of the packed tower 1, a heat exchanger 5 is installed on the inlet pipe 4, and a drain pipe 6 is arranged on the lower side of the packed tower 1 , a collection box 7 is installed at one end of the discharge pipe 6, an exhaust pipe 2 is welded on the upper side of the packing tower 1, a dehumidification box 3 is installed on the exhaust pipe 2, and an active carbon filter layer 25 is installed inside the dehumidification box 3, and the packing tower 1- There is a liquid inlet pipe on the side, and the liquid inlet pipe is located at one end of the packing tower 1, and a nozzle is installed. The bottom side of the packing tower 1 is welded with a baffle 18, and a guide rod 19 is welded on the baffle 18, and a guide rod 19 is pierced with a Anti-wave plate 15, two support grids 12 are installed on the inner wall of the packing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com