Biological membrane biochemical reaction system based on ozone and wastewater purifying process

A biochemical reaction and wastewater purification technology, applied in aerobic process treatment, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of low ozone utilization, incomplete oxidation, energy waste, etc. chain rate, reducing operating costs, and improving the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

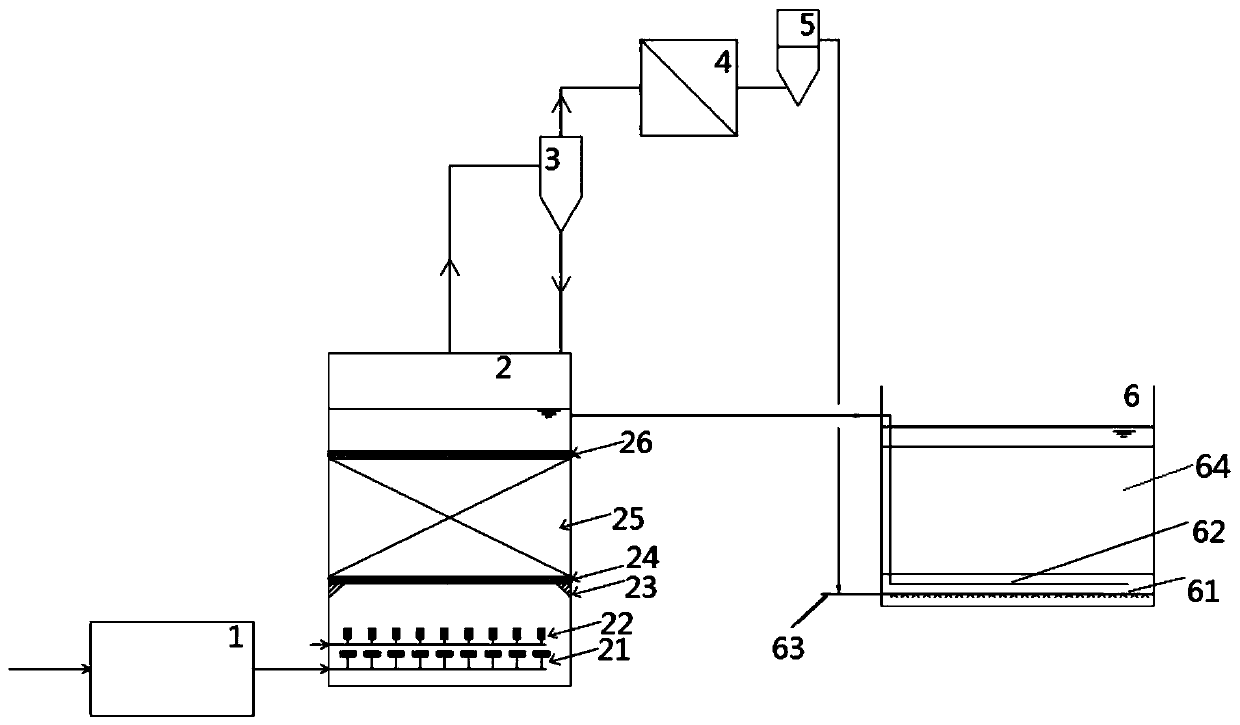

[0068] The invention discloses an ozone-based biofilm biochemical reaction system, such as figure 1 shown, including:

[0069] The ozone reactor 2, the ozone reactor 2 purifies the waste water by using ozone;

[0070] An oxygen-enriched aerated biofilm biochemical reactor 5, which is connected to the ozone generator 1, and is used for deep purification treatment and discharge of the purified wastewater;

[0071] The ozonolysis reactor 4, the ozonolysis reactor 4 communicates with the ozone generator 1 and the oxygen-enriched aerated biofilm biochemical reactor 5 respectively, and is used for decomposing the unreacted ozone after passing through the ozone reactor 2 into oxygen.

[0072] In this embodiment, the mixed gas of ozone (the rest is oxygen) enters the ozone reactor 2 together with the wastewater, and under the action of the catalyst in the ozone reactor 2, the refractory aromatic hydrocarbon organic matter in the wastewater is opened and broken, decomposed into easil...

Embodiment 2

[0074] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the ozone reactor 2 is connected to the ozone generator 1, and the ozone generator 1 is used to decompose pure oxygen to generate a mixed gas of ozone and oxygen.

[0075] The ozone reactor 2 includes: a reactor shell, in which an ozone distributor 21, a water inlet distributor 22, a diversion support ring 23, a catalyst support plate 24, a catalyst layer 25, and a catalyst pressure plate are sequentially arranged from the bottom up in the reactor shell 26.

[0076] The lower surface of the diversion support ring 23 is an inclined plane, which forms an angle of 120-160° with the inner wall of the ozone reactor 2 and is arranged along a circle of the inner wall of the ozone reactor 2 . The ozone gas close to the wall of the device is guided to the inside of the catalyst layer 25 after passing through the slope, without forming a wall flow along the wall of the device.

[0077] Catalyst supporting ...

Embodiment 3

[0080] Such as figure 1 Shown, present embodiment is on the basis of embodiment 2, and the gas outlet of ozone reactor 2 is communicated with the air inlet of mist eliminator 3, and the water outlet of mist eliminator 3 is communicated with the water return port of ozone reactor 2, and demister The gas outlet of mist device 3 communicates with the air inlet of ozonolysis reactor 4, and mist eliminator 3 is used for removing free water.

[0081] Specifically, the gas outlet of the ozonolysis reactor 4 is connected to the dust collector, and the dust collector is connected to the air distribution pipe 61, and the dust collector is used to remove the dust in the purified gas, thereby ensuring the purity of the gas passed into the air distribution pipe 61, The air distribution pipe 61 will not be blocked, and the service time is longer.

[0082] In this embodiment, the main component of the tail gas after the ozone catalytic oxidation reaction is oxygen, in addition, also contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com