high performance liquid chromatography sphere

A high-performance liquid chromatography and chromatographic sphere technology, which is used in measuring devices, instruments, scientific instruments, etc., can solve problems such as easy damage and instability of the column, and achieve stable column, uniform sample distribution, and increased sample loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

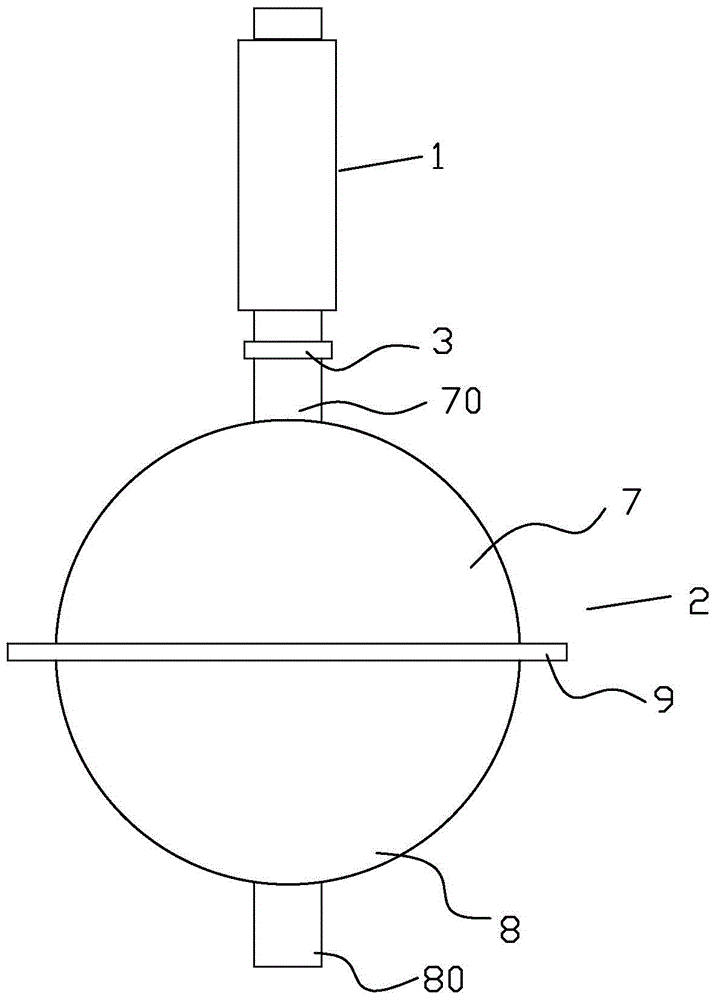

[0031] A high performance liquid chromatography ball, figure 1 As shown, the chromatographic sphere includes a pre-column 1 , a sphere 2 and a first flange device 3 connecting the pre-column 1 and the sphere 2 .

[0032] The sphere 2 is a cavity structure formed by connecting the upper hemisphere 7 and the lower hemisphere 8 through the second flange device 9. The top of the upper hemisphere 7 is provided with an upper tube body 70 communicating with the cavity, and the nozzle of the upper tube body 70 and the pre-column 1 are fixedly connected by the first flange device 3, and the bottom end of the lower hemisphere 8 is provided with a lower pipe body 80 communicating with the cavity.

Embodiment 2

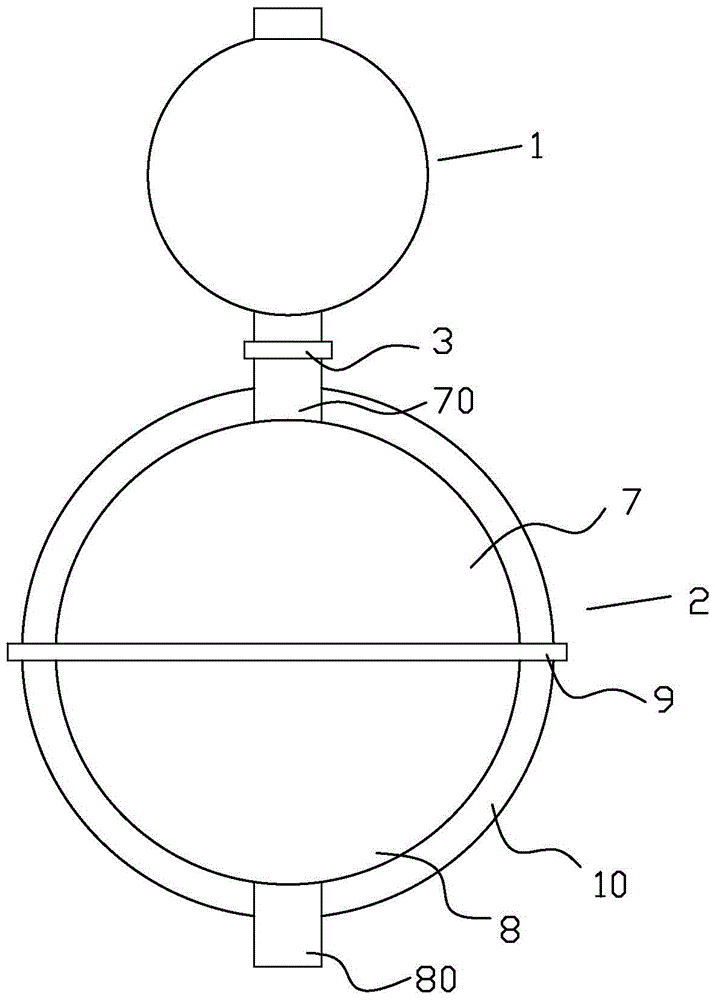

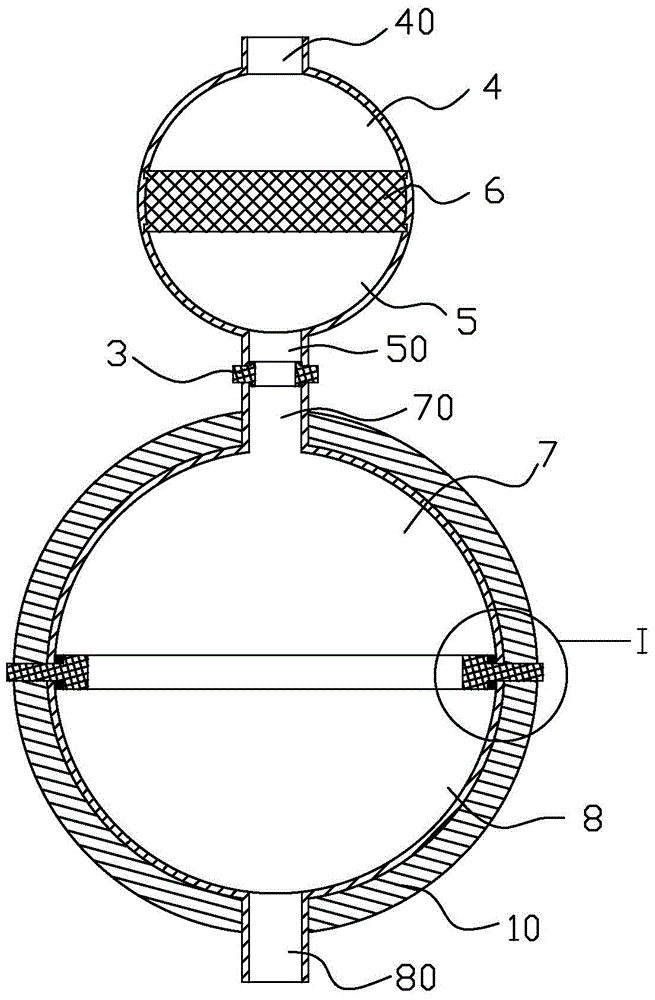

[0034] This embodiment is another implementation method of the high performance liquid chromatography sphere of the present invention. The difference from Example 1 is that, Figure 2~3 As shown, the pre-column 1 is a hollow cavity structure, and the upper half of the column body of the pre-column 1 is a stigma 4, and the lower half is a nozzle 5, and a filtering device 6 is provided in the cavity at the junction of the stigma 4 and the nozzle 5; The cavity cross section of 4 gradually increases from top to bottom, and the cavity cross section of nozzle 5 decreases gradually from top to bottom.

[0035] The pre-column of the present invention is not specifically limited on the premise of satisfying the above-mentioned structure. Preferably in this embodiment, the connection between the column head 4 and the shower head 5 forms a spherical shape with a cavity; the upper end of the column head 4 is provided with an upper pipe 40 , The lower end of the spray head 5 is provided wi...

Embodiment 3

[0039] This embodiment is another implementation method of the high performance liquid chromatography sphere of the present invention. The difference from the embodiment 1 is that the bottom of the lower hemisphere 8 is provided with a confluence mechanism, which is described in detail as follows.

[0040] Image 6 As shown, the bottom end of the lower hemisphere 8 extends upwards by 1 / 3 and a base 12 is provided. The upper nozzle of the lower tube body 8 extends upwards to the upper end of the base 12 , and the diameter gradually increases to form a bell mouth 81 . A manifold 13 is disposed above the base 12 , and a second sieve plate 14 is disposed above the manifold 13 . The upper end of the second flange device 9 is provided with a filter sheet 15 .

[0041] The chromatographic sphere of the present invention has a simple structure, and an outer cladding 10 may be provided outside the sphere 2, and the material of the outer cladding 10 is epoxy resin.

[0042] The filler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com