Spraying system

A technology of spraying system and spraying layer, applied in the field of spraying system, can solve the problems of affecting the distribution of flue gas and spraying effect, short-circuit spraying effect of flue gas, increasing the resistance of flue gas, etc., so as to reduce the amount of spraying slurry , Enhance the spray effect, reduce the effect of span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

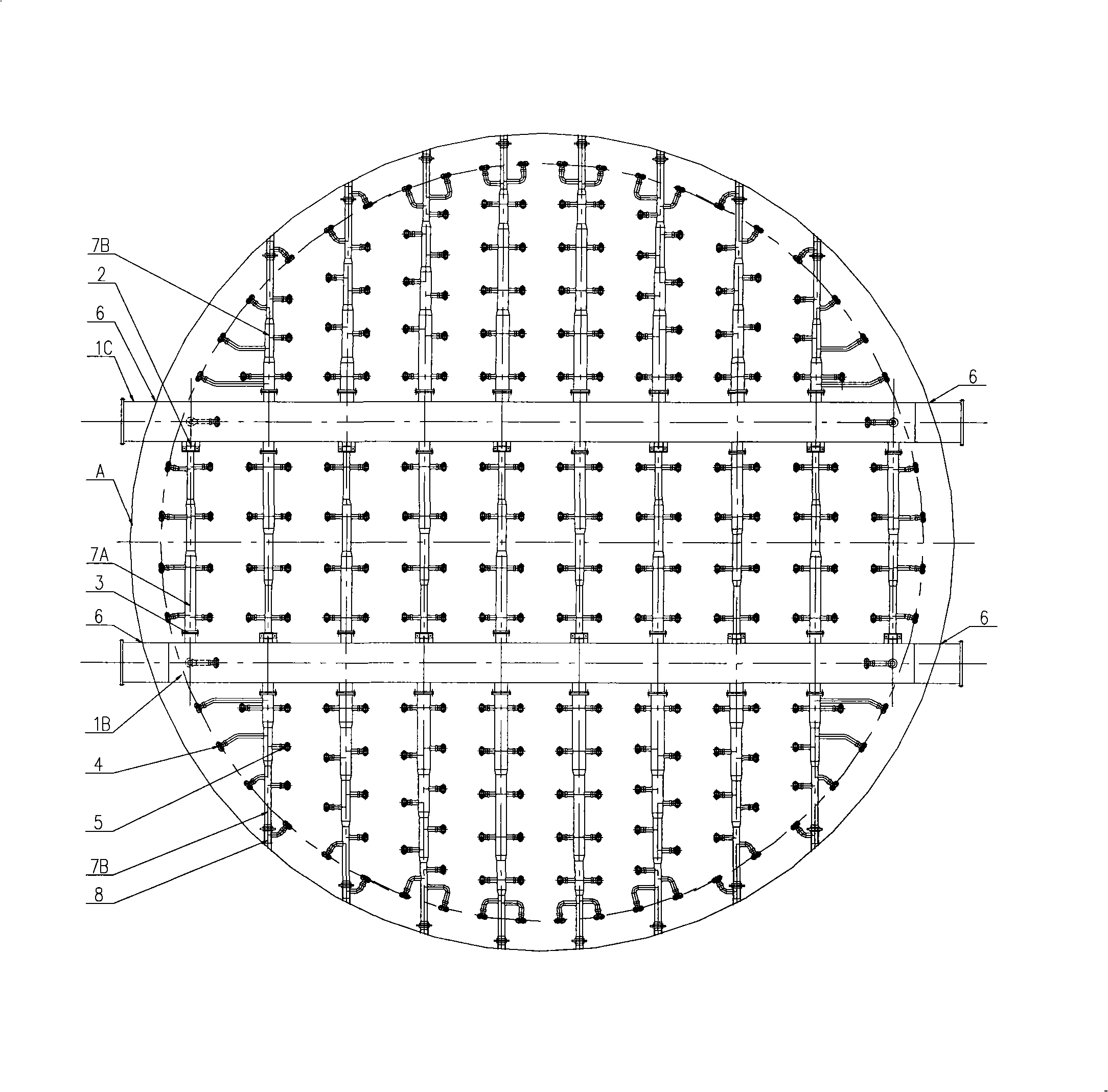

[0018] As shown in the drawings, in the spraying system of the present invention, there are several layers of spraying layers, and two parallel spraying main pipes are arranged on each spraying layer, which are respectively spraying main pipe 1B and spraying main pipe 1C. The two ends of the shower main pipe 1B and the spray main pipe 1C pass through the hole 6 on the wall of the absorption tower and are supported on the wall of the absorption tower, and the section of the spray layer of the absorption tower is divided into three parts:

[0019] The connection form of the spray branch pipe 7A in the middle part and the spray main pipe 1B and the spray main pipe 1C is that one end is connected in the form of a flange (connected through the pipe interface 3 with a flange), and the other end is supported by a slidable saddle Form connection (through the pipe connection 2 of the saddle support). The inlet directions of the spray branch pipes 7A between the spray main pipe 1B and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com