Enamel suspending agent and enamel steel plate with enamel suspending agent

A technology of suspending agent and enamel, which is applied in the field of suspending agent and its application, can solve problems such as difficulty in ensuring the operability of glaze slurry, difficulty in realizing enamel color, and inability to take into account cost issues, achieving low cost, not easy to burn spots, and easy construction good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

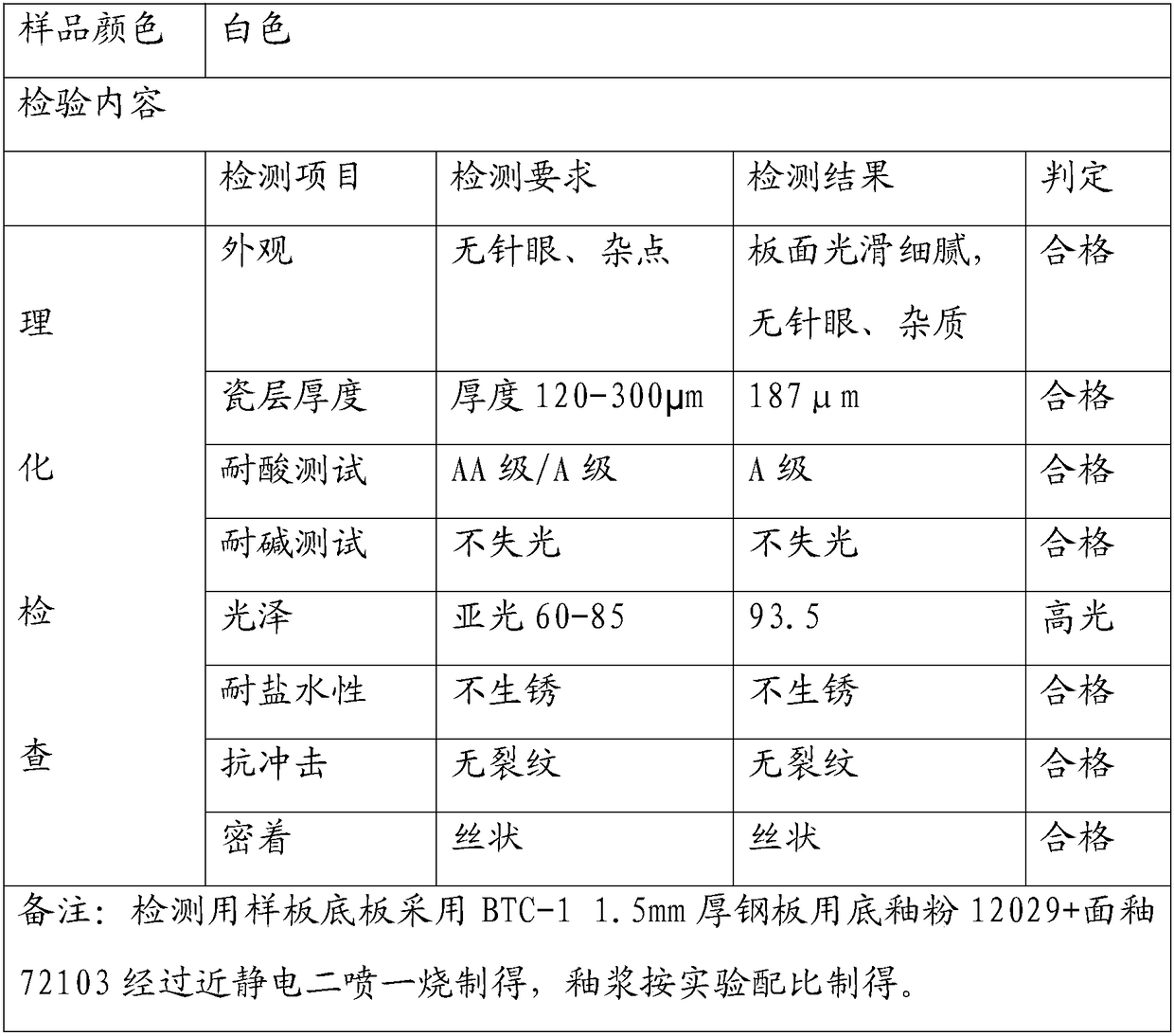

[0019] Weigh the raw materials according to the following proportions: pure titanium glaze TMW 170:100g, Foshan Puji brand suspending agent methylcellulose mixture UC-D1: 8g, potassium chloride: 0.2g, water: 45g, mix well and place in a fast ball mill The glaze slurry produced by upper grinding for 12 minutes was sprayed on the normal enamel plate, the thickness of the enamel layer was 80 μm, and the firing process was 800 ° C for 4 minutes to obtain an enamel steel plate. The specific performance parameters of the obtained steel plate are shown in Table 1.

[0020] Table 1 Enamel inspection results

[0021]

[0022]

[0023] It can be seen from Table 1 that the properties of the enamel steel plate made by UC-D1 meet the standard requirements, and the construction performance is good, which can be applied in the production of enamel.

Embodiment 2

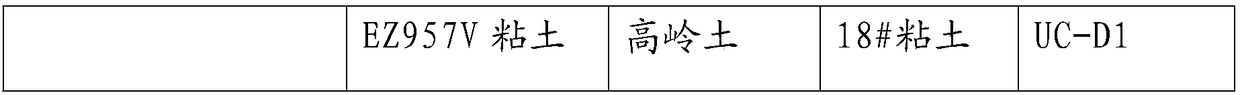

[0025] Weigh each raw material according to the following proportions: pure titanium glaze TMW 170:100g, suspending agent: 7.5g, potassium chloride: 0.2g, water: 45g, wherein, suspending agent is respectively: 1, EZ957V clay, 2, Bailong brand Kaolin, 3. Duomad's 18# clay, 4. Puji's UC-D1, after mixing evenly, grind it on a fast ball mill for 12 minutes. The glaze slurry produced is sprayed on the normal enamel plate, and the thickness of the porcelain layer is 90μm , and the firing process was 800°C for 4 minutes to obtain enamelled steel plates. The performance parameters of the obtained four groups of enameled steel plates are shown in Table 2.

[0026] Table 2 Performance test results of four groups of enamelled steel plates

[0027]

[0028]

[0029] It can be seen from Table 2 that the color of the enamel steel plate prepared by enamel suspending agent UC-D1 is the lightest after comparison in the same direction, and the effect is better than that of the conventiona...

Embodiment 3

[0031] Weigh each raw material according to the following ratio: pure titanium glaze TMW 170:100g, suspending agent: 8g, potassium chloride: 0.2g, water: 45g, wherein, suspending agent is respectively: 1, EZ957V clay 4g, UC-D14g, 2 , Kaolin 4g, UC-D14g, 3, 18# clay 4g, UC-D14g, after mixing evenly, grind it on a fast ball mill for 12 minutes to make the glaze slurry spray on the normal enamel plate, the thickness of the porcelain layer is 100μm, and fire The process is 800°C for 4 minutes to produce enamelled steel plates. The performance parameters of the three groups of enameled steel plates obtained are shown in Table 3.

[0032] Table 3 Performance comparison of glaze slurry prepared by different schemes at the same time

[0033]

[0034] Comparing the data in Tables 2 and 3, it can be seen that the color of the enamel produced after mixing different suspending agents is still yellowish, which cannot meet the requirement of a color of about 3. It can be seen that the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com