Oil deposit purification sewage sand-carrying filling sand prevention method and sand prevention pipe column

A technology for sand control pipes and sewage, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of affecting the permeability of oil reservoirs, easy to block sand filter pipes, and production decline, etc., so as to ensure filling and sanding. The success rate of construction, the effect of ensuring smooth sand addition and preventing process settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

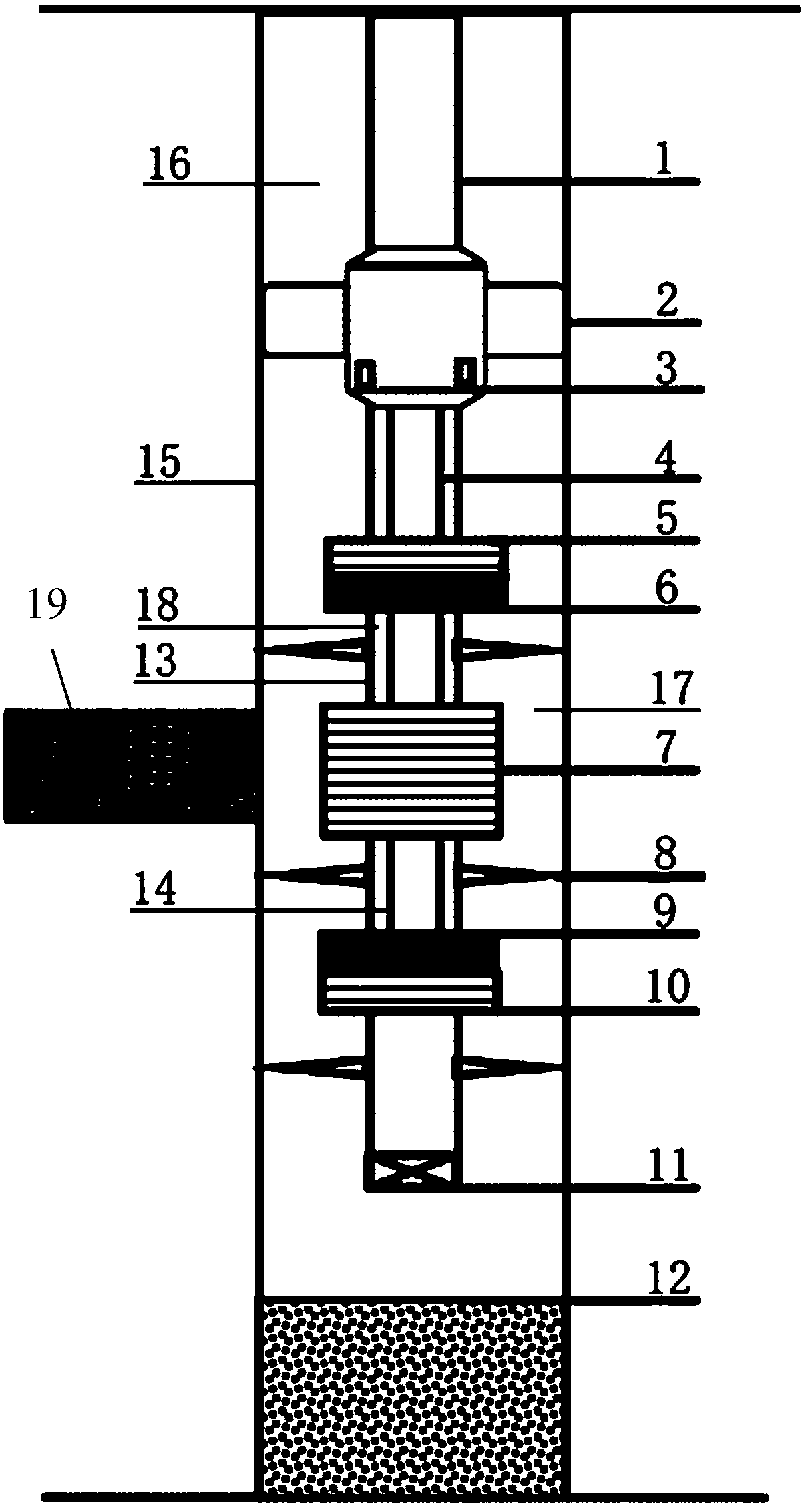

[0038] The sand control string of this embodiment, such as figure 1 As shown, it includes a top packer 2, a top sand control tool assembly, a sand control screen 7, a bottom sand control tool assembly and a plug 11. The upper part of the top packer 2 is connected to the oil filling pipe 1; the plug 11 is connected to the The artificial sand surface 12 keeps a certain distance;

[0039] The top packer 2, the top sand control tool assembly, the sand control screen 7, the bottom sand control tool assembly, and the plug 11 are sequentially connected from top to bottom through the tubing sub-joint 13 to form an outer tubing string, and the outer tubing string is connected to the casing An outer annular space 17 for filling sand control is formed between the pipes 15, wherein the sand control screen 7 is located at the corresponding position of the sand control layer 19; the top sand control tool assembly includes the top signal screen 5 and sand control The compensator 6; the bott...

Embodiment 2

[0044] In this embodiment, the sand control method for oil reservoir purification sewage filling with sand, adopts the sand control pipe string as described in Embodiment 1, and specifically includes the following steps:

[0045] 1) The sand surface is scoured, so that the artificial sand surface is 10±0.5m below the lower boundary of the oil layer, so as to meet the needs of sand control strings and sand settlement;

[0046] 2) Open the well, check the technical condition of the casing, and ensure the normal construction and production;

[0047] 3) Scrape the casing to ensure that the upper and lower casing inner walls at the top packer setting position are clean;

[0048] 4) The pressure test of the pipe string is qualified to ensure that there is no leakage when the pipe string is filled;

[0049] 5) According to the design requirements, the sand control string with the top packer described in Embodiment 1 is lowered into the predetermined position in the well, so that the...

Embodiment 3

[0058] In this embodiment, the sand control method for oil reservoir purification sewage filling with sand, adopts the sand control pipe string as described in Embodiment 1, and specifically includes the following steps:

[0059] 1) The sand surface is scoured, so that the artificial sand surface is 10±0.5m below the lower boundary of the oil layer, so as to meet the needs of sand control strings and sand settlement;

[0060] 2) Open the well, check the technical condition of the casing, and ensure the normal construction and production;

[0061] 3) Scrape the casing to ensure that the upper and lower casing inner walls at the top packer setting position are clean;

[0062] 4) The pressure test of the pipe string is qualified to ensure that there is no leakage when the pipe string is filled;

[0063] 5) According to the design requirements, the sand control string with the top packer described in Embodiment 1 is lowered into the predetermined position in the well, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com