Selective garbage screening and feeding device and method

A technology for feeding and garbage, applied in the field of selective garbage screening and feeding devices, can solve the problems of inability to automatically sort large materials, blockage of transmission equipment, wear and other problems, and achieve convenient subsequent sorting, strong conveying capacity, and feeding. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The selective waste screening and feeding method involved in the present invention is mainly realized through the following steps.

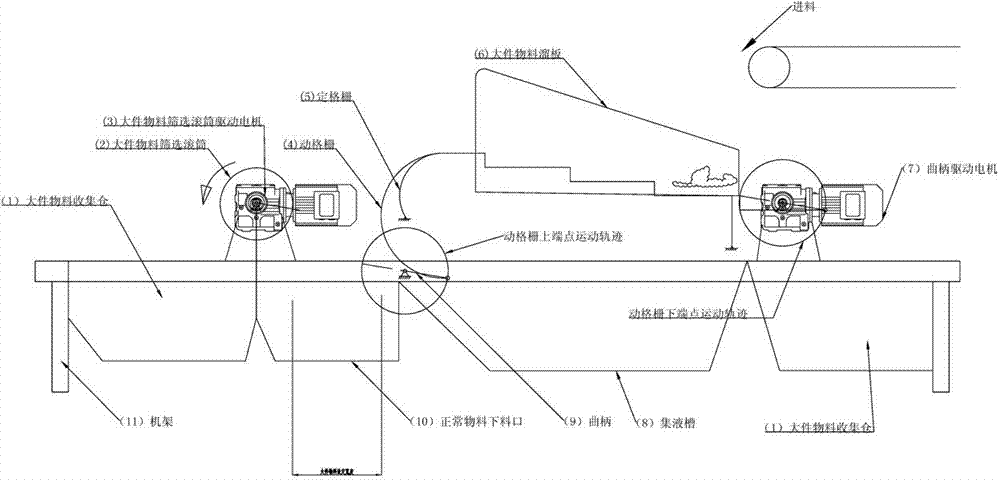

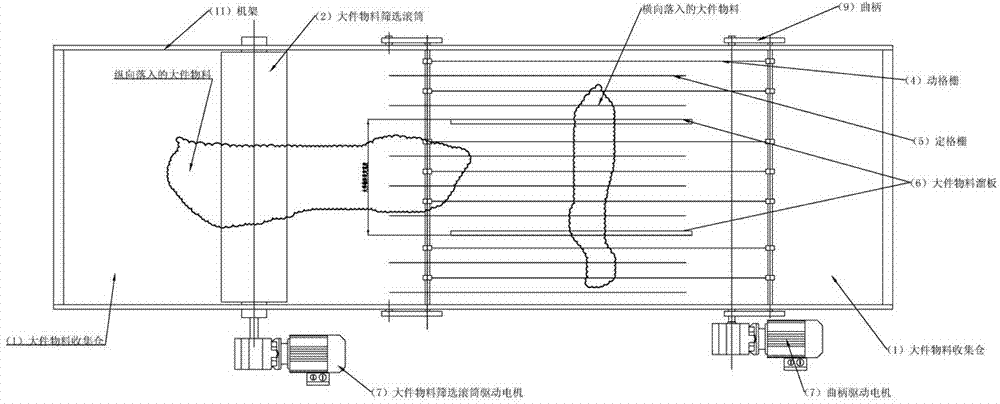

[0007] See attached figure 2 , Two large-size material slides are arranged longitudinally and symmetrically on both sides of the longitudinal centerline of the equipment, dividing the grid feeding plane into 3 feeding planes longitudinally. Material whose horizontal or vertical size is larger than the specified material size is regarded as "large material". When the large material straddles the large material slide (6) horizontally, the material will fall from the inclined plane formed by the slide due to gravity. To the bulky material collection bin (1); when the bulky material falls into the feed inlet along the longitudinal direction of the slide, the material will be transported to the unloading mouth periodically along with the grid (4), at the unloading mouth A large-size material screening drum (2) is provided. The large-size materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com