Low-temperature evaporation and concentration system for desulfurization wastewater

A technology for desulfurization wastewater and low-temperature evaporation, which is applied in the field of low-temperature flash evaporation and concentration systems, can solve the problems of high operation cost and insufficient operation safety and stability of the filtration reduction method, and achieves new load adaptability, low operation cost, and low intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

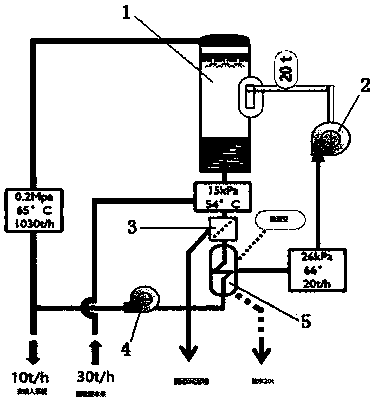

[0037] like figure 1 As shown, for thermal power plants. The desulfurization wastewater low-temperature evaporation concentration system includes a wastewater heating system, a wastewater flash treatment system, and a flash vapor suction compression system.

[0038] The wastewater flash treatment system of its core treatment device includes a flash tank and a flash circulation system; the upper part of the flash tank is a spray flash mechanism, the bottom is equipped with a water tank, the side is a steam outlet, and a droplet separation device is installed. Wastewater is sprayed into the flash tank in the form of mist or droplets, and is evaporated and cooled during the air time, and the part that has not been flashed falls into the bottom tank. Then it is filtered, and enters the waste water heating system to raise the temperature, and then re-pumps to the upper part of the flash tank through the waste water circulation pump to form the spray flash evaporation mechanism. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com