Technology for preparing nanometer ceramic particle material with industrial propane

A technology of nano-ceramic particles and industrial propane, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of complex process of nano-particle materials, high price of nano-particle materials, high production cost, etc., and achieve high sphericity and crystallinity The effect of controllable type and reduction of production cost

Inactive Publication Date: 2002-06-05

DALIAN UNIV OF TECH

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditional particle material processing and synthesis methods are used in the processing and synthesis of nanoparticle materials, which have the disadvantages of complex process and other shortcomings.

Although the existing flame vapor deposition method for preparing nanoparticle materials has a simple process, due to the use of carbon monoxide or hydrogen as fuel, the prepared nanoparticle materials are expensive and difficult to market

High production cost is the bottleneck problem restricting the further development of nanoparticle materials prepared by flame vapor deposition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

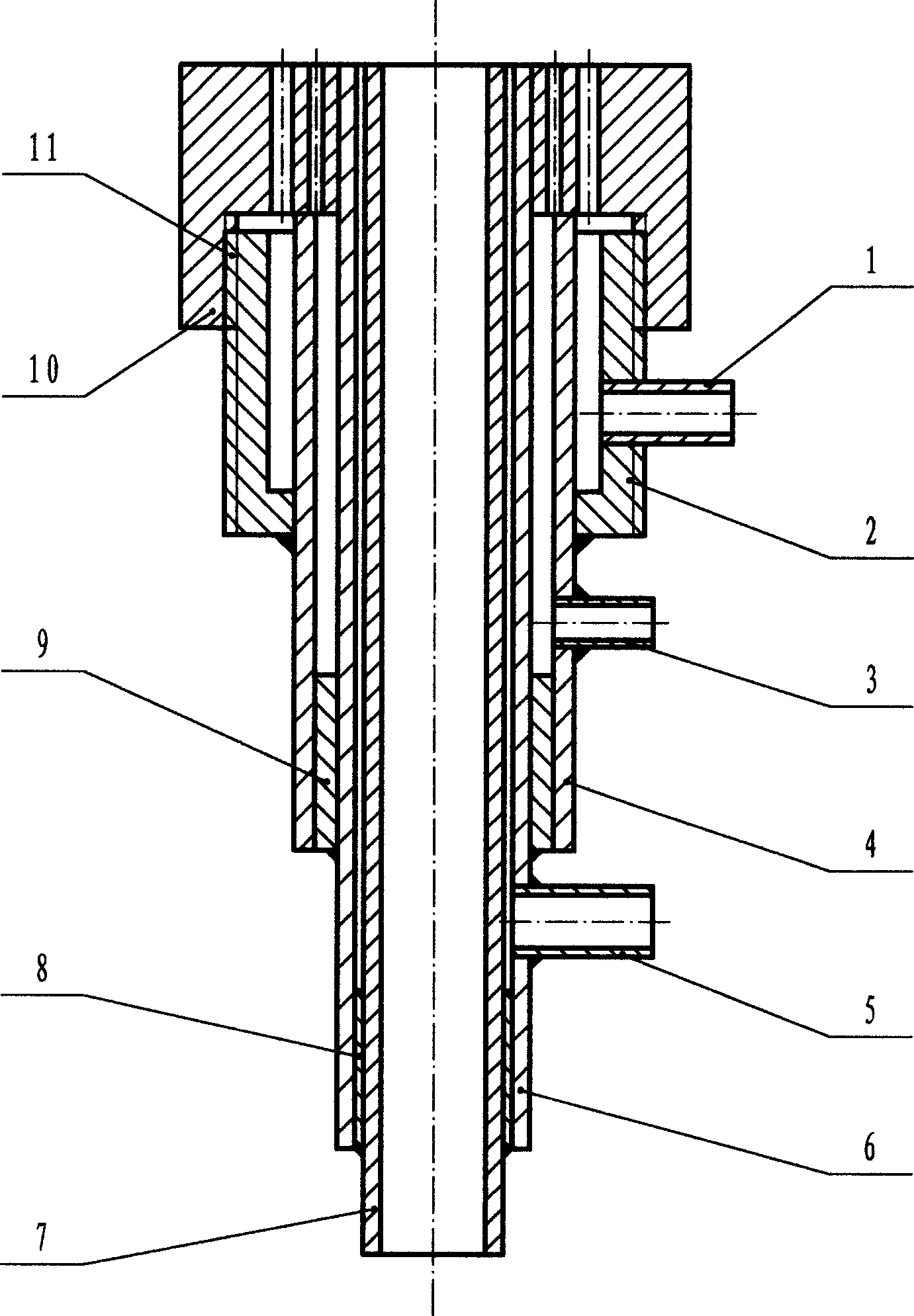

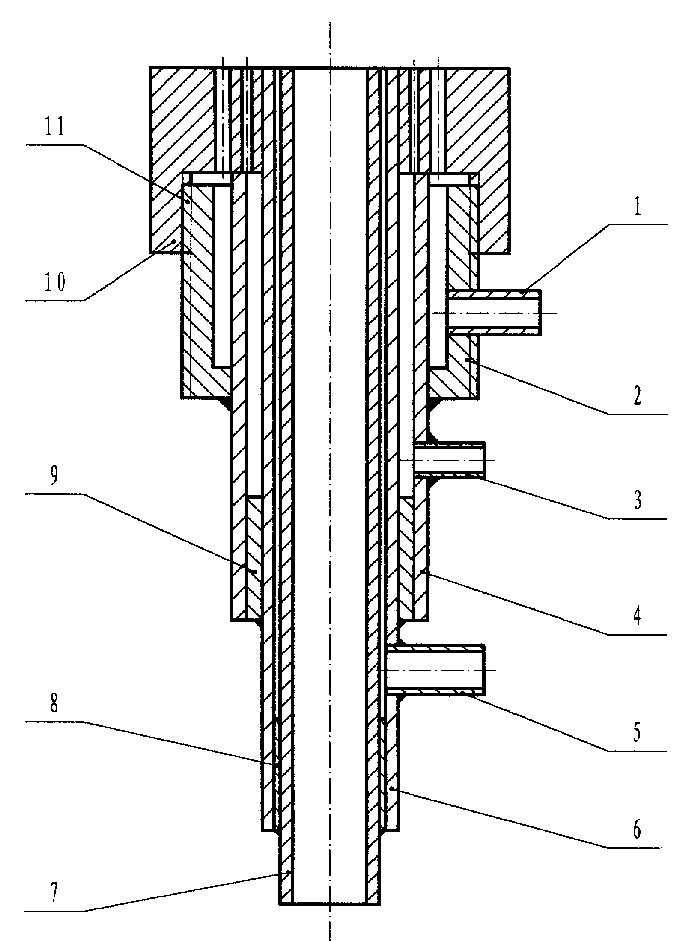

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] For example, to prepare titanium dioxide nanoparticle materials, the crystal form is rutile crystal form, the average particle size is 50 nanometers, and the output is 4 grams per hour.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to the field of new material technology, and a technique for prparing nm ceramic particle material by use of industrial propane. The present invention features the technological scheme of designing a combustion nozzle and controlling the particle for collecting temperature and pressure to prepare nanometer ceramic particle material with the flame gas phase deposition process. The present invention has simple technological process, producing nanometer ceramic particle material low cost in, high in product purity, with uniformly distributed grain sizes, high spherical degree, average grain size of 10-100 nm and controllable crystal form, etc. The nanometer ceramic particle material may find its wide application in catalyst, functional paint, functional fiber material, fine ceramic material, cosmetics, etc.

Description

technical field [0001] The invention belongs to the technical field of new materials, and in particular relates to a technology for preparing nanometer ceramic particle materials by using industrial propane as a fuel flame vapor deposition method. Background technique [0002] Due to the unique physical and chemical properties of nanomaterials, the processing and synthesis technology of nanomaterials, especially nanoparticle materials, has been listed as a priority field of new materials by various countries. Traditional particle material processing and synthesis methods used in the processing and synthesis of nanoparticle materials have disadvantages such as complex process. Although the existing flame vapor deposition method for preparing nanoparticle materials has a simple process, due to the use of carbon monoxide or hydrogen as fuel, the prepared nanoparticle materials are expensive and difficult to market. High production cost is the bottleneck problem restricting the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G23/07C04B35/622C04B35/64

Inventor 谢洪勇宁桂玲王达望

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com