Noncorrosive compression-resisting explosion-suppressing material and preparation method thereof

A corrosion-resistant and explosion-suppressed technology, used in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of loss of explosion-suppression, shortened service life, corrosion, etc., achieve good retardation and heat absorption, and improve corrosion resistance. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

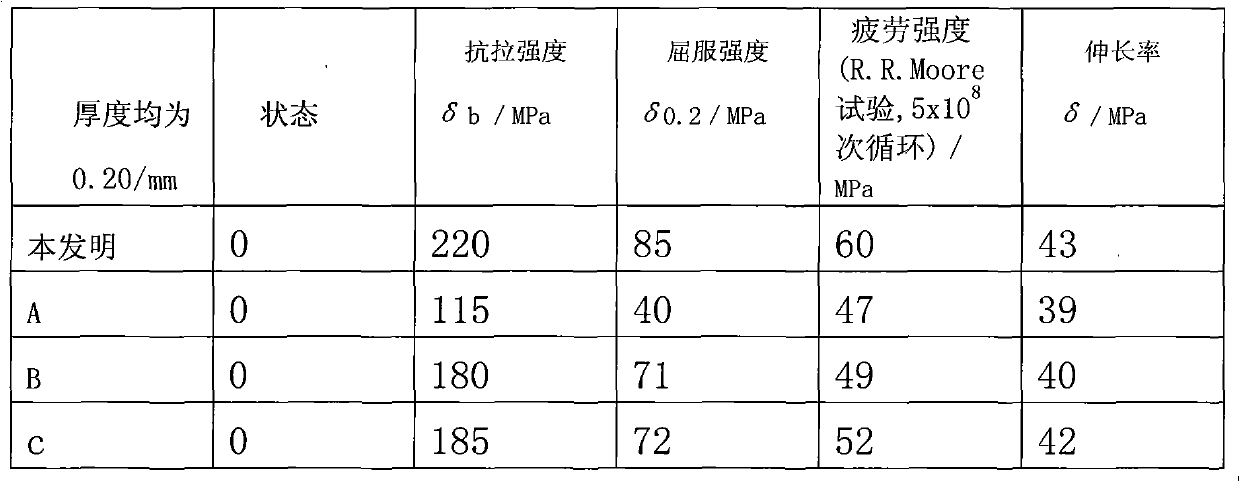

Image

Examples

Embodiment Construction

[0021] The weight percentage of the chemical composition of the anti-corrosion, anti-depression and anti-explosion material of the present invention is: Si0.03~0.08, Fe0.03~0.05, Cu0.02~0.04, Mn0.9~1.5, Mg0.9~1.5, Zn0.09~ 0.15, Ce0.09~0.12, Al balance; a rare earth film is provided on the outer surface of the honeycomb mesh explosion suppression material.

[0022] The weight percent of the chemical composition of the preferred anti-corrosion, anti-depression and anti-explosion material of the present invention is: Si0.05~0.07, Fe0.04~0.05, Cu0.03~0.04, Mn1.3~1.5, Mg1.3~1.5, Zn0. 12 to 0.14, Ce0.09 to 0.11, Al balance; a rare earth film is provided on the outer surface of the honeycomb mesh explosion suppression material.

[0023] The preparation method of the anti-corrosion, anti-pressure and explosion-suppressing material of the present invention includes putting the explosion-suppressing material of the above-mentioned chemical composition into a melting furnace and heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com