Method for drying sludge by blade drier

A paddle dryer and paddle technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of huge tail gas treatment system, unsatisfactory use effect, difficult long-term operation of equipment, etc., to avoid heat transfer With dry deterioration, good drying effect, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

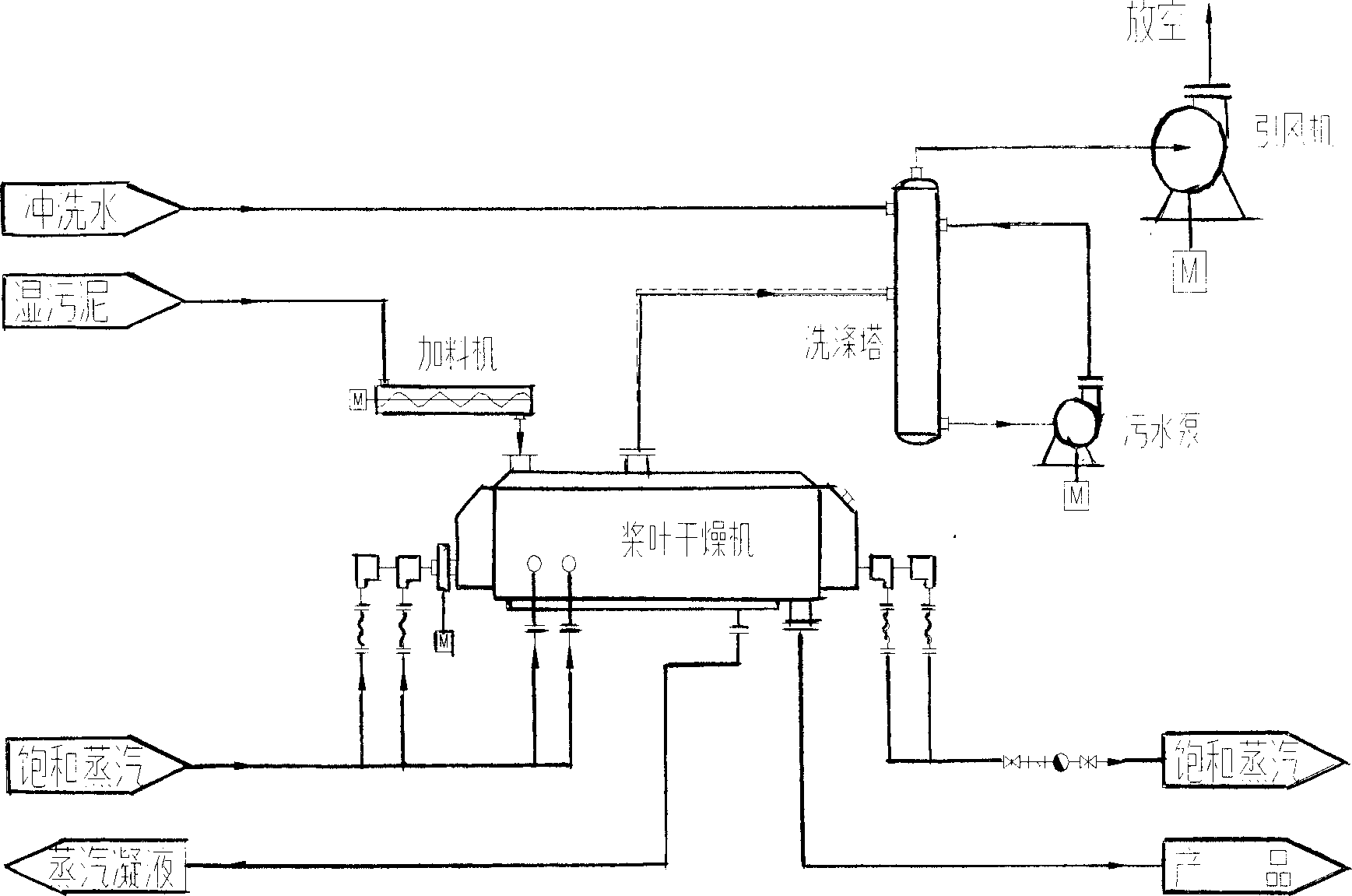

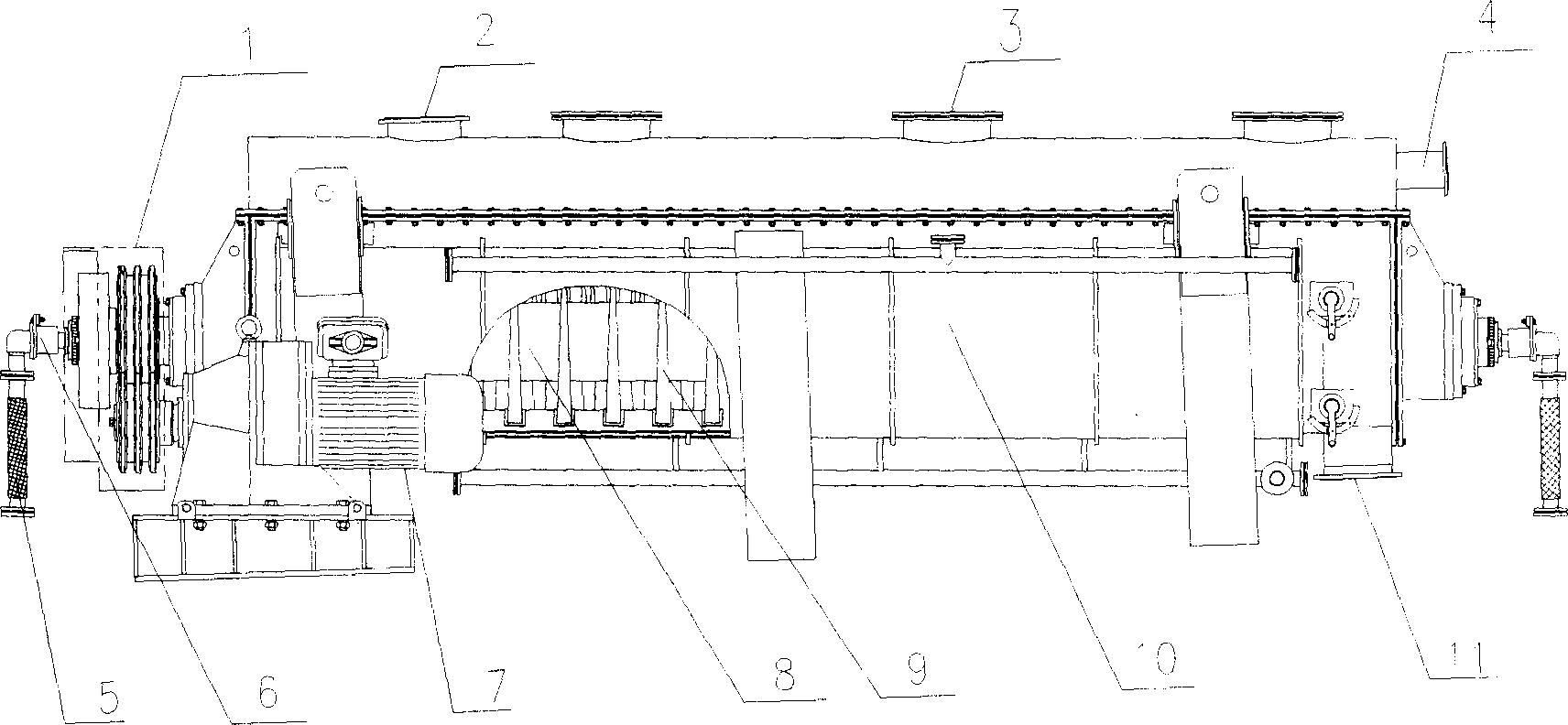

[0022] Such as figure 1 figure 2 As shown, the oily sludge of the oil refinery with a moisture content of 87% is continuously and uniformly added to the paddle dryer (patent number: ZL 01 265998.3) from the feed port 2 of the paddle dryer by a single screw feeder, with 0.6MPa ( G) Saturated steam is the heat medium. The heat medium enters the hollow heat shaft 8 of the paddle dryer and the shell jacket 10 of the paddle dryer through the inlet 5 through the rotary joint 6. There is a wedge-shaped paddle 9 on the heat shaft 8, and the heat shaft 8 is driven by the motor of the transmission system 1 and the reducer 7; the wet material is vaporized under the indirect heating of the heat medium through the heat shaft 8 and the shell jacket 10 of the paddle dryer, and the material is dried while drying on the hollow paddle. Stirring and pushing of the heat shaft 8 moves to the discharge port 11, the product output and humidity are controlled through the rotation speed of the hollo...

Embodiment 2

[0024] The chemical plant biochemical sludge with a moisture content of 82% is continuously and evenly fed into the paddle dryer from the feed port 2 of the paddle dryer through a double-screw conveyor; 0.6MPa (G) saturated steam is used as the heat medium, and the heat medium The inlet 5 enters the hollow blade thermal shaft 8 of the paddle dryer and the shell jacket 10 of the paddle dryer through the rotary joint 6. The thermal shaft 8 is driven by the motor of the transmission system 1 and the reducer 7; the wet material passes through the heat medium Under the indirect heating of the heat shaft 8 and the shell jacket 10 of the paddle dryer, the moisture is vaporized, and while the material is being dried, it moves to the discharge port 11 under the stirring and pushing of the heat shaft 8, and the control of product output and humidity Through the adjustment of the rotating speed of the hot shaft 8 and the height of the overflow plate at the outlet of the dryer, the moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com