A Coal Mine Wet Shotcrete Process

A technology of spraying and coal mines, which is applied in mining equipment, shaft lining, tunnel lining, etc., can solve the problems of low spraying efficiency, large amount of excavation engineering, increased loading and unloading procedures, etc., and achieve optimal selection of raw materials and cheap raw materials Easy to obtain and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

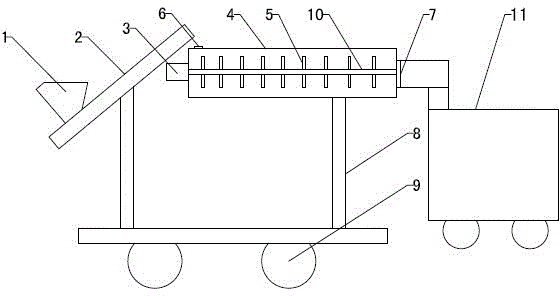

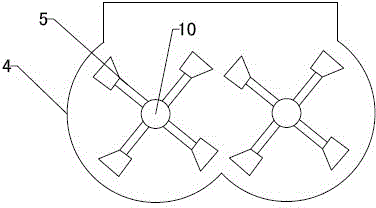

[0035] Figures 1~3 is the best embodiment of the present invention, the following is combined with the appendix Figures 1~3 The present invention will be further described.

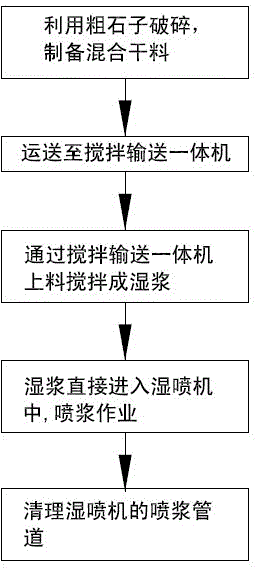

[0036] Refer to the attached Figures 1~3 : This coal mine wet shotcrete process includes the following steps:

[0037] 1. Preparation of mixed dry material: Set up a centralized mixing station for raw materials on the ground, crush coarse stones with a particle size of 20~40mm through a self-percussion sand making machine, and mix them with machine-made sand to produce adjustable and granular particles with a particle size of less than 10mm. The grade distribution is continuously adjustable and the preparation process is free of drying sand and gravel mixture; then the sand and gravel mixture, cement, fly ash, water reducing agent, fiber, and accelerator are dry-mixed and stirred to form a mixed dry material, which is then installed. The bag is spare; the weight of each bag is about 25kg;

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com