A self-cleaning curtain wall decorative board and its processing technology

A self-cleaning and decorative board technology, applied to walls, biocide-containing paints, coatings, etc., can solve the problems of poor self-cleaning effect, uneven powder dispersion, poor stain resistance, etc., to ensure outdoor use. Performance requirements, the effect of protecting original performance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

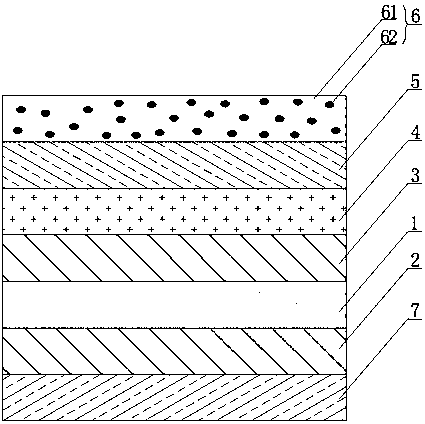

[0047] A self-cleaning curtain wall decorative panel in this embodiment, combined with figure 1 , consisting of substrate layer 1, passivation layer one 2, passivation layer two 3, primer layer 4, topcoat layer 5, self-cleaning layer 6 and back paint layer 7, passivation layer one 2, passivation layer two 3 Located on the lower surface and the upper surface of the substrate layer 1 respectively, the back paint layer 7 is located below the passivation layer 1 2, the primer layer 4 is located on the passivation layer 2 3, the primer layer 4, the top coat layer 5 and the self-cleaning layer 6 Arranged sequentially from bottom to top; the self-cleaning layer 6 is a film-like fluoropolymer 61 formed by a water-soluble fluoropolymer, wherein nanoscale titanium dioxide or titanium dioxide / silicon dioxide are prepared by sol-gel method to form titanium dioxide (or Titanium dioxide / silica composite) gel 62. Specifically in this embodiment, the titanium dioxide (or titanium dioxide / sil...

Embodiment 2

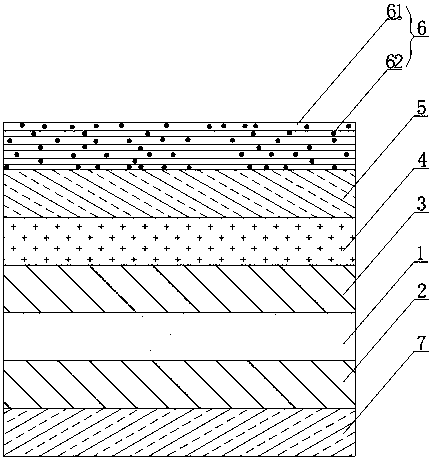

[0057] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference lies in: combining figure 2 , the fluoropolymer 61 is provided with multiple layers, in the fluoropolymer 61, the titanium dioxide (or titanium dioxide / silica composite) gel 62 is granular, and the titanium dioxide (or titanium dioxide / silica composite) gel 62 is embedded in The titanium dioxide (or titanium dioxide / silica composite) gel 62 between the top layer and the bottom layer of the fluoropolymer 61 and the multilayer fluoropolymer 61 form a self-cleaning layer 6 .

Embodiment 3

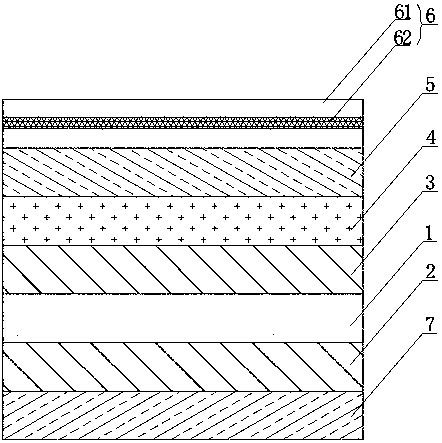

[0059] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference lies in: combining image 3 , titanium dioxide (or titanium dioxide / silica composite) gel 61 is a layered structure, the titanium dioxide (or titanium dioxide / silica composite) gel 62 is a strip or layered structure, which is located in the fluoropolymer 61 , titanium dioxide (or titanium dioxide / silicon dioxide composite) gel 62 and fluoropolymer 61 form a self-cleaning layer 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com