Special intelligent logistics vehicle for workshop

An intelligent logistics and workshop technology, applied in the field of warehouse logistics vehicles, can solve the problems of being unable to pass through uneven roads and slopes, and achieve the effects of low maintenance costs, protection of the working environment, and high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

[0020] In order to help understand the above-mentioned basic mode of the present invention, describe with reference to accompanying drawing:

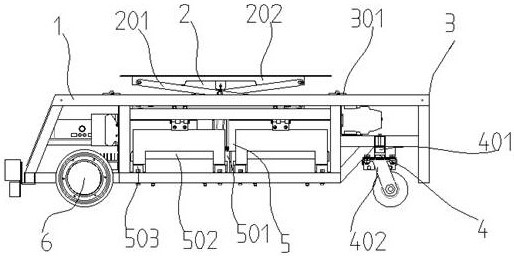

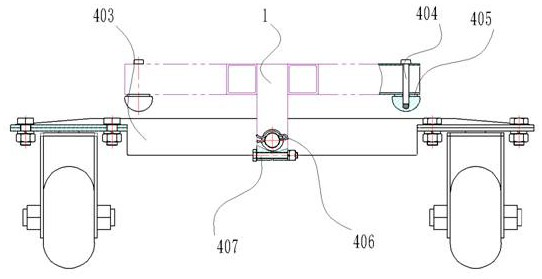

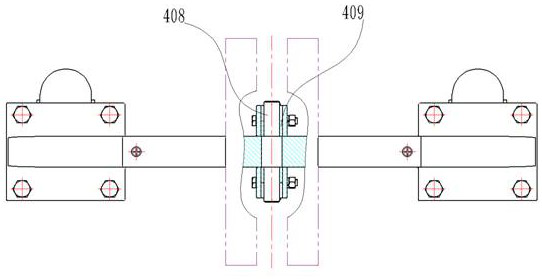

[0021] The special intelligent logistics vehicle for the workshop, including: frame 1, lifting device 2, vehicle shell 3, rear axle assembly 4, battery positioning device 5, hub servo motor 6. It is characterized in that: the driving system of the special intelligent logistics vehicle for the workshop consists of a frame 1, a hub servo motor 6, a rubber universal wheel 402, a rear axle 403, a rear axle hinge shaft 408, a sliding bearing 409, a limit buffer block 401, The limit adjustment screw 404, the limit adjustment washer 405, and the spring cotter pin 406 are formed. The two hub servo motors 6 are rigidly connected to the vehicle frame 1 at the front end of the vehicle frame 1, and the two rubber universal driven wheels 402 are rigidly connected to the rear axle 403 through bolts, and the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com