ballast excavation device

A technology of excavation device and ballast, which is applied in the field of railway track cleaning and screening equipment, can solve problems such as difficulty in equipment, and achieve the effects of reducing space requirements, overcoming lack of space, and improving working conditions and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

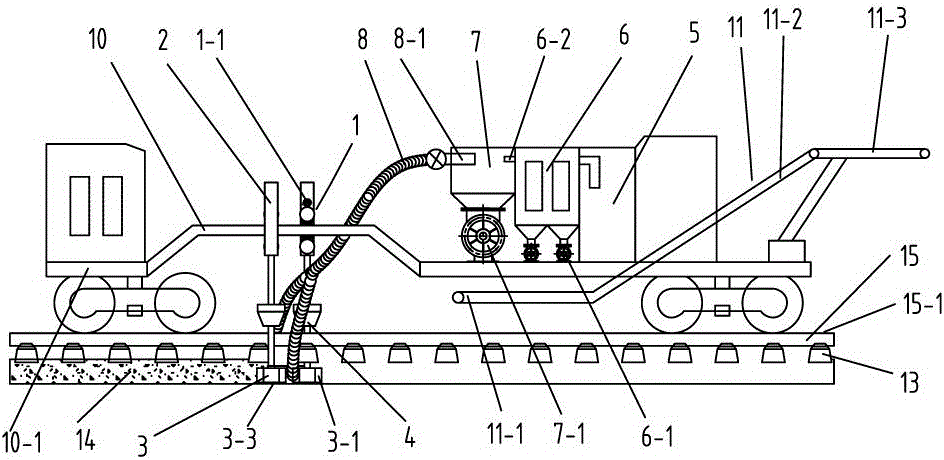

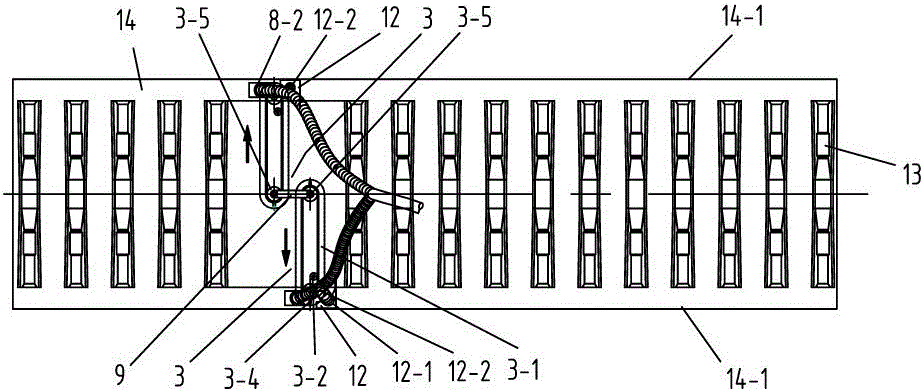

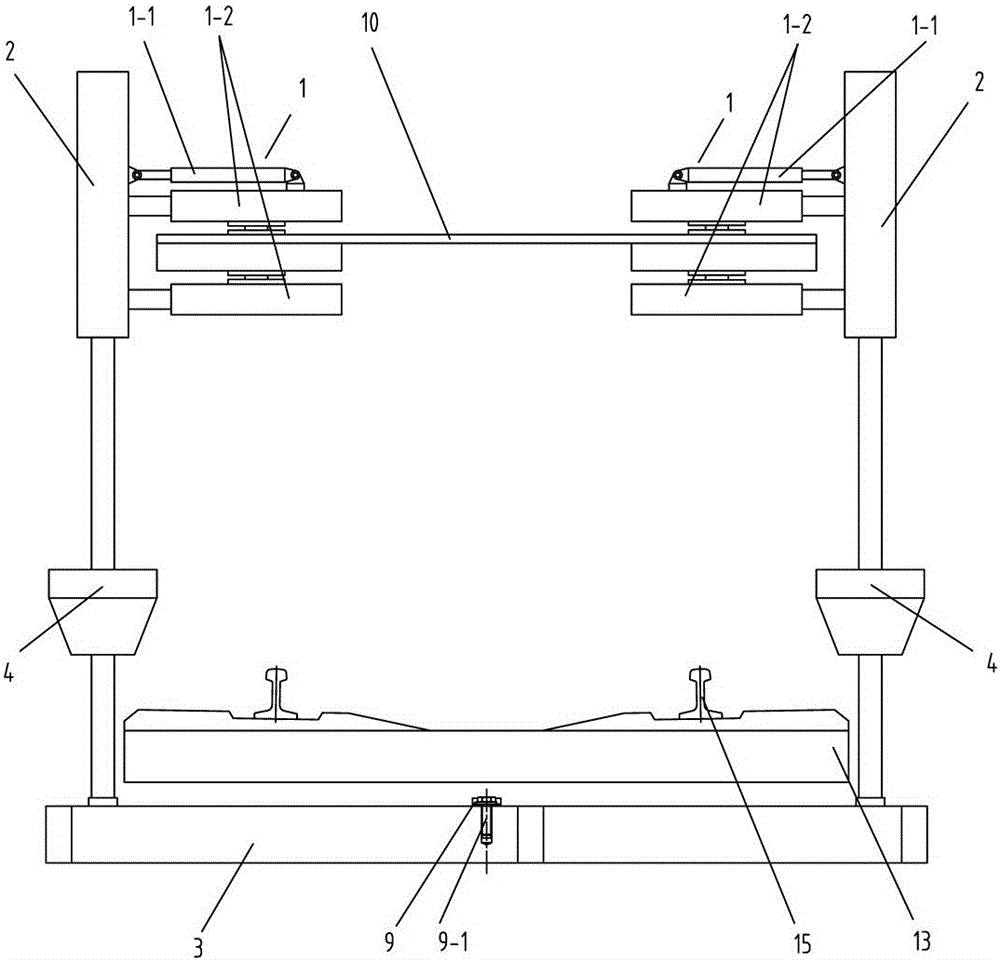

[0032] Such as Figure 1-5 As shown, a ballast excavation device of the present invention includes a vehicle frame 10, a ballast excavation mechanism and a ballast conveying device. The excavation mechanism includes a lifting cylinder 2, a drive motor 4, and an excavation chain assembly 3. The lifting The oil cylinder 2 is connected to the vehicle frame 10, the lifting oil cylinder 2 is connected to the drive motor 4, and the drive motor 4 is connected to the excavation chain assembly 3. The excavation chain assembly 3 has an excavation sprocket 3-5, an annular ballast removal chain 3-1 and The rake teeth 3-4, the excavation sprocket 3-5 mesh with the ring-shaped ballast removal chain 3-1, and the ring-shaped ballast removal chain 3-1 is equipped with rake teeth 3-4, and the ballast conveying device includes a ballast suction pipe 8, Ballast storage 7, ballast filter 6, vacuum suction pump 5 and conveyor belt 11, the suction port 8-2 of the ballast suction pipe 8 is located ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com