Efficient ground paving and levelling machine

A leveler and ground technology, applied in the directions of roads, road repair, roads, etc., can solve the problems of affecting the construction efficiency and quality of cement ground, not suitable for paving operations, low plastering efficiency, etc., to achieve high paving quality, The effect of good flatness and fast paving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

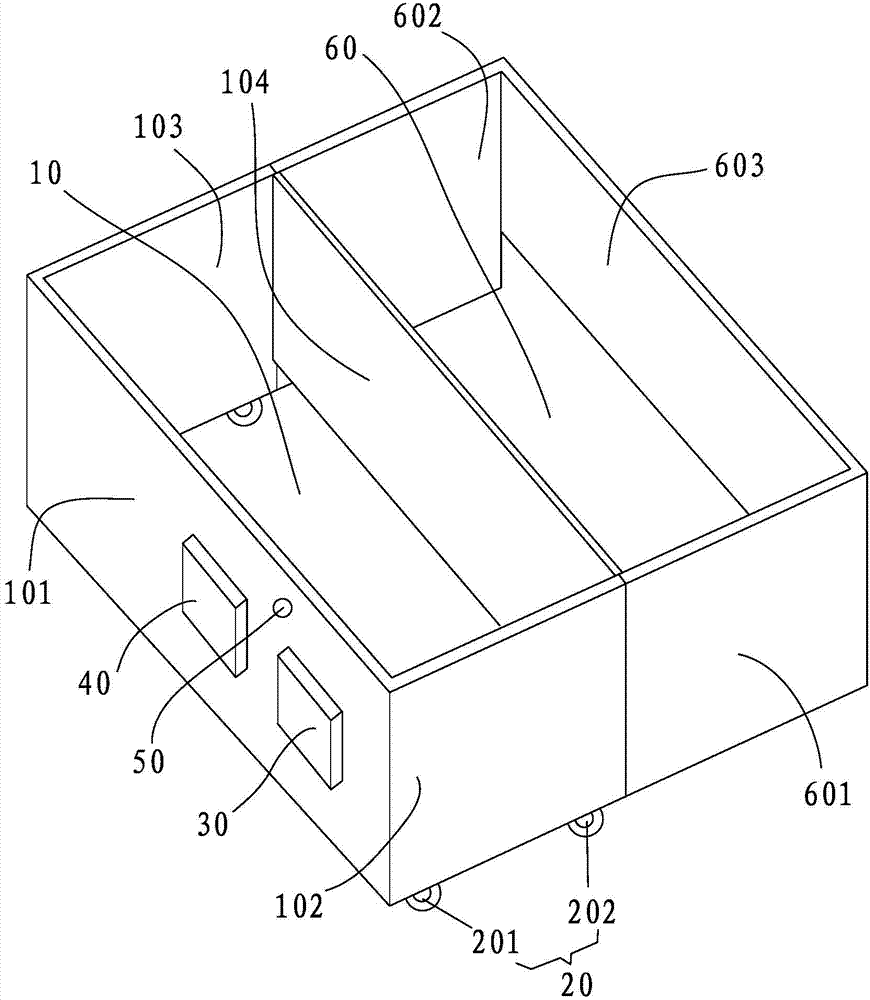

[0039]First, two flat roller walking tracks are set on the ground that needs to be paved, and then the present invention is placed on the roller walking tracks, and semi-wet mortar or wet mortar is manually added to the first accommodation cavity 10 . Mortar, turn on the power supply 40, turn on the control switch 50, start the motor 30, and drive the universal wheel 201 to rotate, so that the high-efficiency ground paving and leveling machine of the present invention runs automatically, because the rear panel A104 is slightly higher than the front panel A104 The bottom of the panel A101, the left side panel A102 and the right side panel A103, so that the semi-wet mortar or wet mortar placed in the first storage chamber 10 is automatically leaked and spread on the ground evenly, and semi-wet mortar needs to be paved Mortar or wet mortar floors are paved.

[0040] Thereby, compared with the traditional leveler, the present invention can carry out rapid paving operation through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com