Double-sided metal clad plate and manufacturing method thereof

A technology of double-sided metal and production method, which is applied in the field of building decoration materials, can solve problems such as high pollution, high cost, and great natural hazards, and achieve the effects of cost reduction, convenient production, and high-end decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

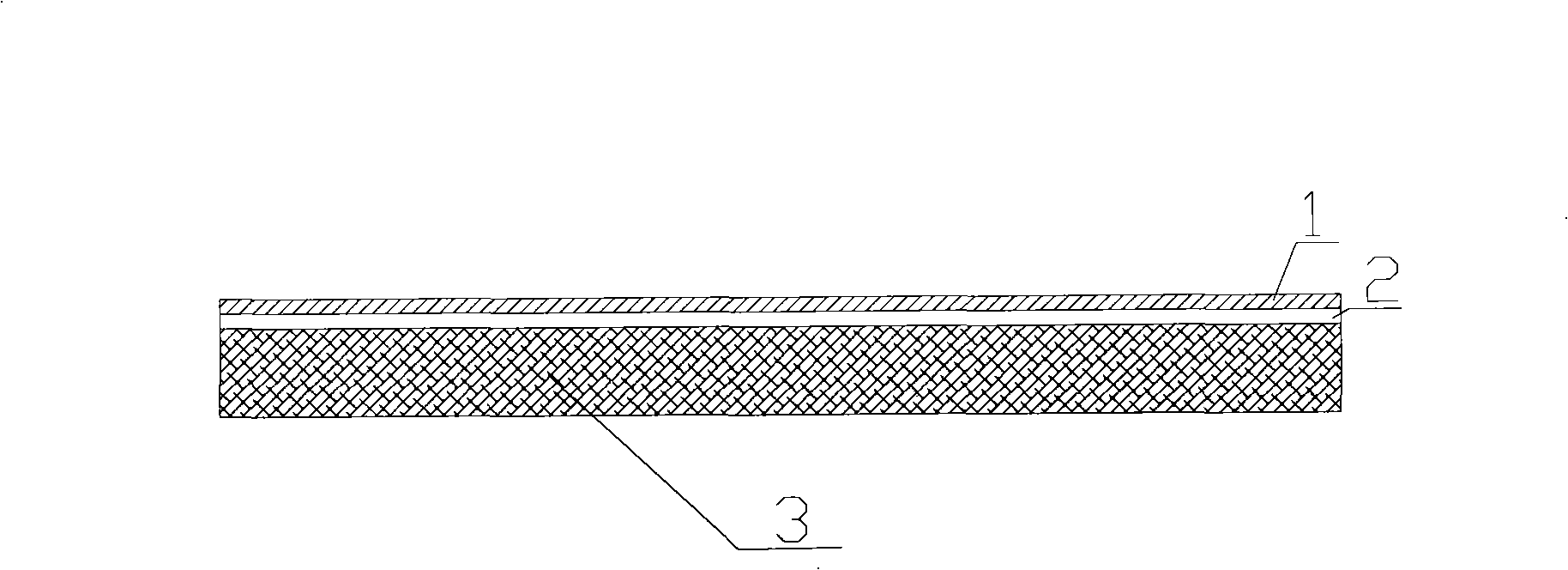

[0016] Example: such as figure 1 As shown, the double-sided metal composite board is composed of a panel 1, an intermediate layer 2 and a substrate 3. The panel 1 can select non-ferrous metal foils or plates with a thickness of 0.05 to 1.5 mm as the surface material to form the panel, and the material can be red copper, brass, titanium stainless steel, or stainless steel. The substrate 3 can be a common metal plate with a thickness of 0.1 mm to 3 mm as a base material to constitute the substrate. The intermediate layer 2 is a polymer material adhesive.

[0017] The choice of materials for the panel 1 and the substrate 3 can be diversified, as described below: choose a non-ferrous metal foil or strip with a thickness of 0.05 to 1.5 mm as the surface material, and the material can be copper, brass, titanium stainless steel, or stainless steel. A common metal strip with a thickness of 0.1mm to 3mm is selected as the base material, and the material can be galvanized steel or rust-proo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com