Flocked aluminum alloy plate and preparing method thereof

An aluminum alloy plate and flocking technology, which is applied in the field of plate processing, can solve the problems that the car cannot meet the requirements and the strength is not enough, and achieve the effect of luxurious decoration, soft hand feeling and preventing water droplets from dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

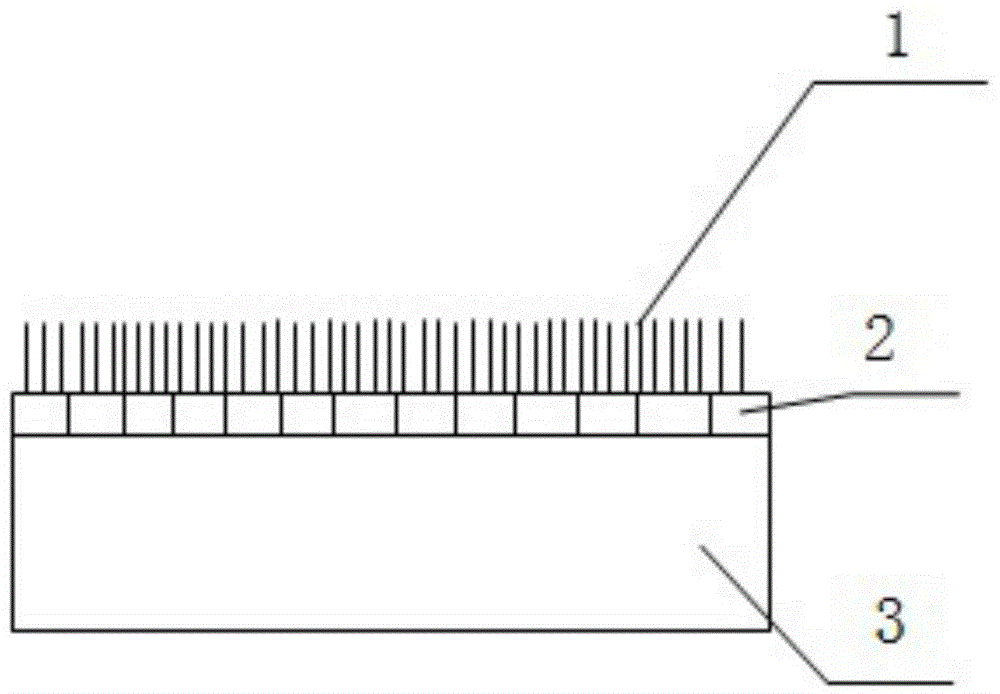

[0029] Such as figure 1 As shown, a flocking aluminum alloy sheet of the present invention, the flocking aluminum alloy sheet includes three layers, and the three layers are respectively a fluff layer, a glass fiber mesh cloth layer and an aluminum alloy sheet layer;

[0030] The preparation method of the flocking aluminum alloy plate of the present invention comprises the following steps:

[0031] (1) Surface pretreatment: first, put the clean, unoiled aluminum alloy plate with a thickness of 0.18mm and a width of 800mm into the surface treatment machine for surface pretreatment of coating the surface treatment agent. Treatment, the coated board surface treatment agent is RC300 passivator produced by Nippon Paint, the single-side coating speed of the board surface treatment agent is 13m / min, and the single-side coating amount of the board surface treatment agent is 1.0g / m 2 , the temperature of the board surface treatment agent is 20°C when coating,

[0032] (2) Drying trea...

Embodiment 2

[0040] Such as figure 1 As shown, a flocking aluminum alloy sheet of the present invention, the flocking aluminum alloy sheet includes three layers, and the three layers are respectively a fluff layer, a glass fiber mesh cloth layer and an aluminum alloy sheet layer;

[0041] The preparation method of the flocking aluminum alloy plate of the present invention comprises the following steps:

[0042] (1) Board surface pretreatment: first, put the aluminum alloy sheet with a clean surface, unoiled, 1.2mm in thickness and 1000mm in width into the surface treatment machine for surface pretreatment of coating the surface treatment agent. Treatment, the coated board surface treatment agent is RC300 passivator produced by Nippon Paint, the single-side coating speed of the board surface treatment agent is 18m / min, and the single-side coating amount of the board surface treatment agent is 0.8g / m 2 , the temperature of the surface treatment agent is 22°C when coating;

[0043] (2) Dryi...

Embodiment 3

[0050] Such as figure 1 As shown, a flocked aluminum alloy sheet of the present invention includes three layers, and the three layers are a fluff layer, a glass fiber mesh layer and an aluminum alloy sheet layer.

[0051] The preparation method of the flocking aluminum alloy plate of the present invention comprises the following steps:

[0052] (1) Surface pretreatment: first, put the clean, unoiled aluminum alloy plate with a thickness of 0.9mm and a width of 1250mm into the surface treatment machine for surface pretreatment of coating the surface treatment agent. Treatment, the coated board surface treatment agent is RC300 passivator produced by Nippon Paint, the single-side coating speed of the board surface treatment agent is 15m / min, and the single-side coating amount of the board surface treatment agent is 0.6g / m 2 , the temperature of the surface treatment agent is 25°C when coating;

[0053] (2) Drying treatment: After the plate surface treatment agent is coated, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com