Precision shaping compounding machine for jacquard fabric

A technology of jacquard cloth and composite machine, which is applied to layered products, lamination devices, lamination, etc., which can solve the problems of low machine production efficiency, obvious color difference, and high labor intensity, and achieve the reduction of labor intensity of workers and the improvement of machine performance. The effect of reducing consumption and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

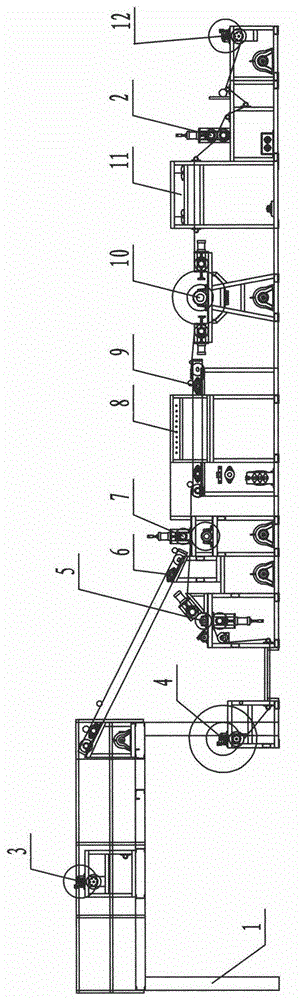

[0009] Such as figure 1 As shown, the jacquard cloth precision shaping compound machine includes: a frame 1, a traction device 2 arranged on the frame 1, a jacquard cloth constant tension unwinding device 3 arranged at the front end of the frame 1, and a nonwoven constant tension unwinding device Device 4, a gluing device 5 is arranged on the frame 1 behind the non-woven fabric constant tension unwinding device 4, and a preliminary needle edge is arranged on the frame 1 behind the jacquard constant tension unwinding device 3 Device 6, the preliminary stitching device 6 is arranged on the upper end of the gluing device 5, and a pressing device 7 is arranged on the frame 1 behind the gluing device 5 and the preliminary stitching device 6. The frame 1 behind the closing device 7 is provided with an oven 8, and the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com