Production line for hypersonic flame spraying iron copper aluminum zinc composite boards

A supersonic flame, production line technology, applied in the direction of coating, layered products, melt spraying, etc., can solve the problems of high pollution, high cost, shortage, etc., and achieve cost reduction, good bonding force, smooth board surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

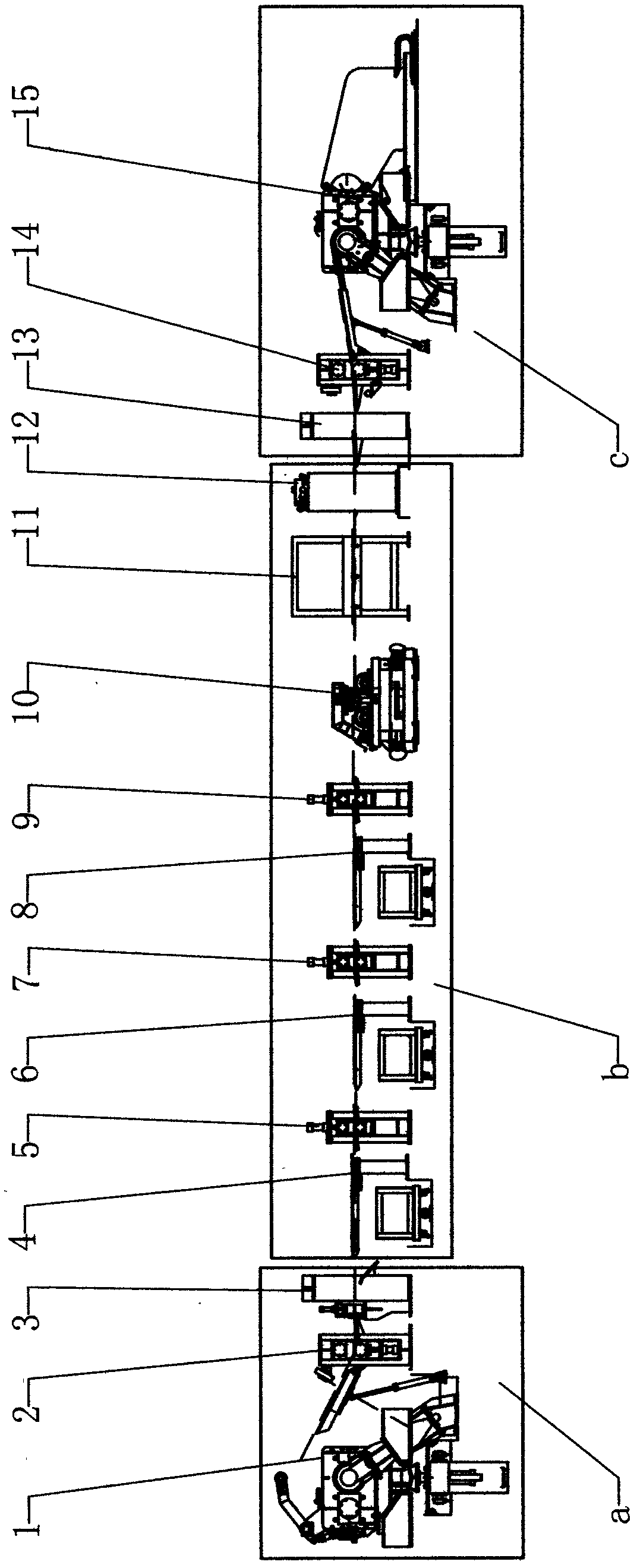

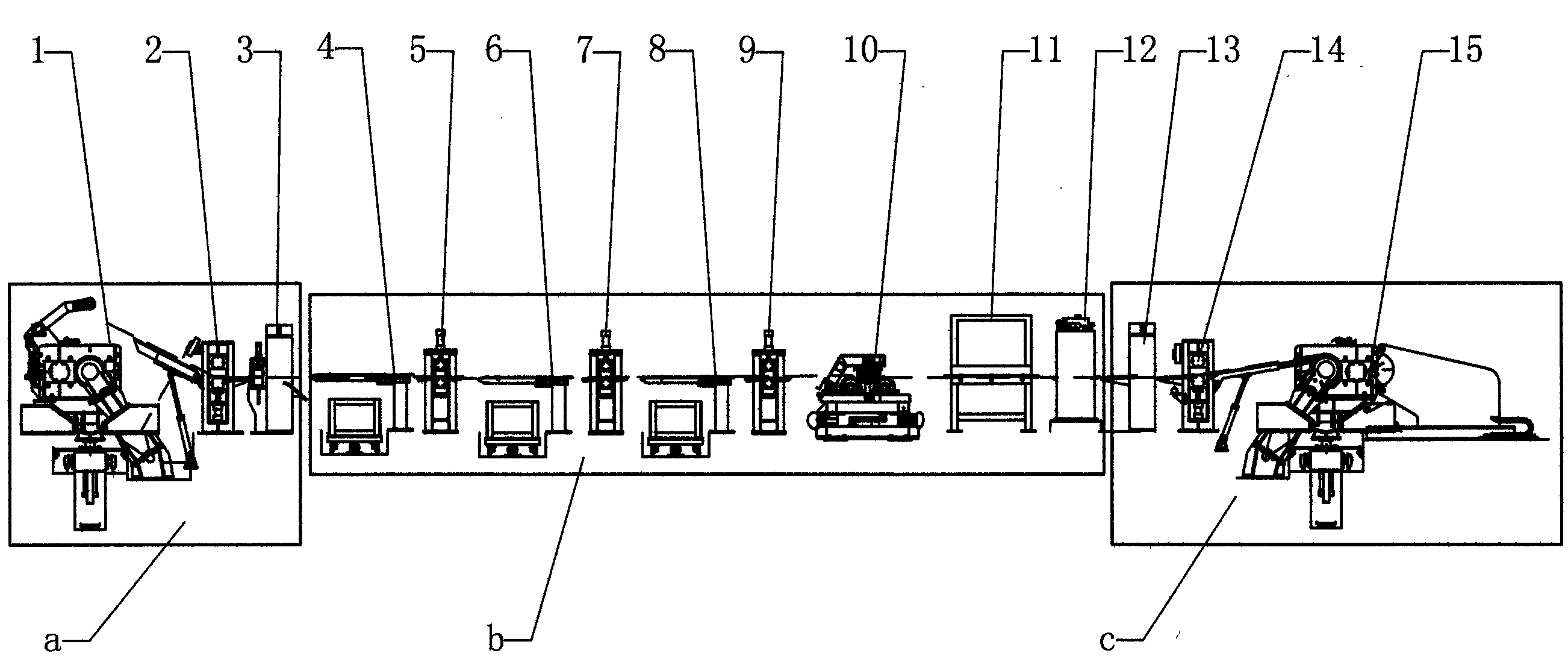

[0011] The specific implementation of the supersonic flame spraying iron-copper-aluminum-zinc composite panel production line of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The invention relates to a multi-layer metal composite board, which uses an iron board as a substrate, zinc as a face plate, and copper and aluminum as a core board to form an iron-copper-aluminum-zinc composite board, that is, an iron-copper-aluminum-zinc four-layer composite board.

[0013] When compounding copper, aluminum and zinc on the iron plate, use a supersonic flame spraying machine (4, 6, 8), that is, sprinkle copper, aluminum and zinc powder on the iron plate in sequence, and use supersonic flame to spray copper, aluminum and zinc The powder is compounded on the iron plate, so that the copper, aluminum and zinc powders are combined with the iron plate in turn to form the copper, aluminum and zinc layers of the composite plate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com