Iridescent Jianzhan firing process

A technology of craft and green body, which is applied in the field of iridescent Jianzhan firing technology, can solve the problems of formula selection, temperature, and atmosphere control, common glaze color of Jianzhan, and low yield rate, etc., so as to shorten the burning time, Gold wire-like boundaries are clear and the yield is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

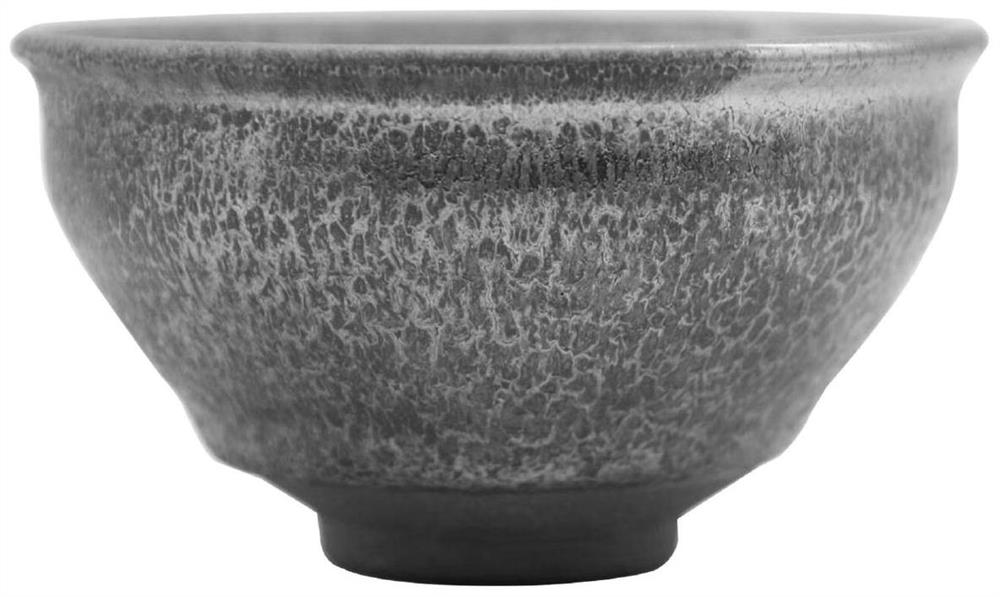

Image

Examples

Embodiment 1

[0050] The firing process of iridescent Jianzhan includes the following steps:

[0051] (1) preparing green body and glaze slurry;

[0052] The green body is prepared by the following method: mixing 4 parts by weight of yellow mud, 2 parts by weight of kaolin, and 6 parts by weight of red clay, crushing, elutriating, passing through an 80-mesh sieve, filtering the mud, and then refining the mud. Old, after aging, mud is smelted to obtain green body raw materials, and the green body raw materials are drawn into shape, trimmed, biscuit, and cooled to obtain the green body;

[0053] The biscuit firing is that the temperature of the kiln is raised from normal temperature to 800° C. at a constant speed within 6 hours, then the furnace is stopped and cooled.

[0054]The glaze slurry is prepared by the following method: elutriating plant ash, stirring, passing through a 100-mesh sieve, standing for 12 hours to separate layers, discarding the water, and obtaining a precipitate as pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com