Preparation method of gold-imitating coating

A coating, golden technology, applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problems of difficult to achieve mass production stably, difficult performance requirements, etc., to achieve small color difference, stable color value, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

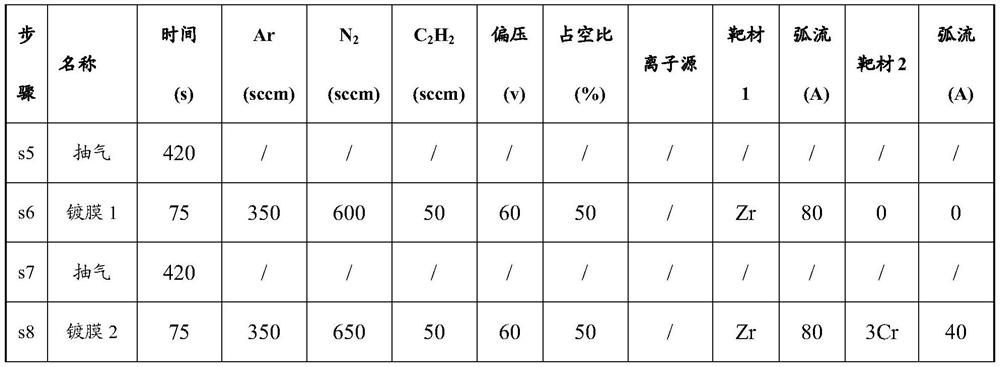

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of gold imitation coating, comprises the steps:

[0028] Step S1: Put the stainless steel parts to be plated into degreasing liquid acetone, degrease, dewax and dedust the surface, and perform surface cleaning treatment;

[0029] Step S2: Load the above parts to be coated into a vacuum coating machine, vacuumize and provide argon as a protective gas, and use a gas ion source device to perform plasma etching on the parts to be coated;

[0030] Step S3: under the protection of argon, bombard the piece to be plated with zirconium high-energy particles after the above treatment, and attach a zirconium ion semi-permeable layer on the surface of the piece to be plated;

[0031] Step S4: using the magnetron multi-arc method to deposit a pure zirconium metal film on the surface of the piece to be plated after the above treatment, as a bottom layer;

[0032] Step S5: Turn on the air extraction to vacuum the inside of ...

Embodiment 2

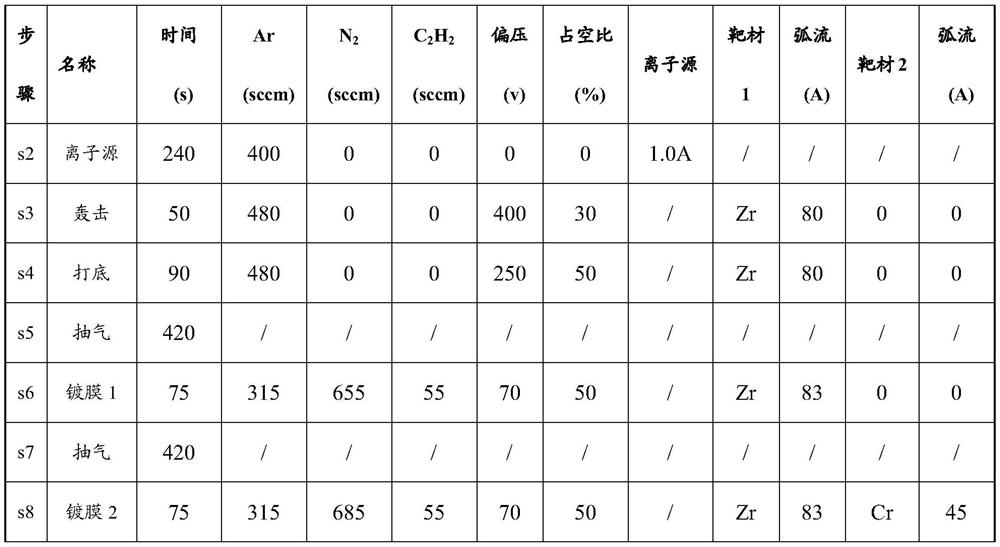

[0040] The steps of this embodiment are the same as those of Example 1. The specific process parameters of steps S2-S5 are the same as those in Table 1. The difference lies in the parameters of steps S6 and S8. The coating thickness of the product is 0.25 μm, as shown in Table 2:

[0041] Table 2

[0042]

Embodiment 3

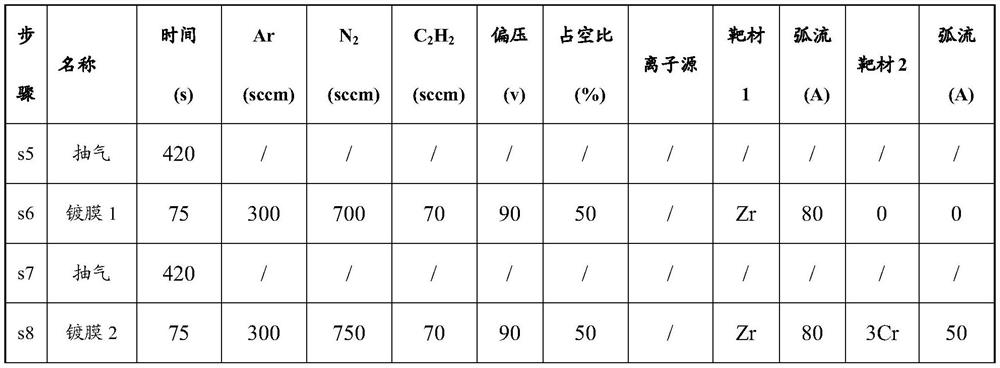

[0044] The steps of this embodiment are the same as those of Example 1. The specific process parameters of steps S2-S5 are the same as those in Table 1. The difference lies in the parameters of steps S6 and S8. The coating thickness of the product is 0.20 μm, as shown in Table 3 below:

[0045] table 3

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com