Gravure lipophilic golden ink and preparation method thereof

A technology of golden ink and plate ester, which is applied in the field of gravure ester-soluble golden ink and its preparation, can solve the problems of poor stability, short retention period, poor metallic effect of golden ink, etc., and achieves strong metallic feeling, long shelf life, Good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

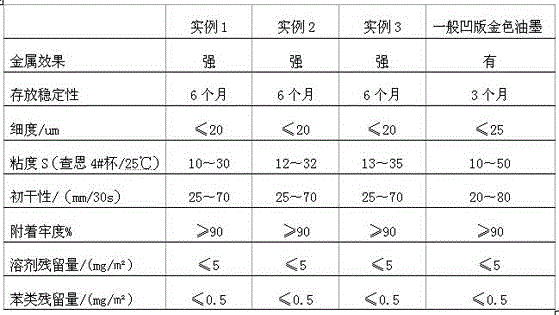

Examples

Embodiment 1

[0023] The yellow pigment is transparent yellow 4400T from DIC Company, the electroplating silver paste is ultra-thin non-leafing super bright aluminum silver paste of 1500 mesh, the ester-soluble polyurethane is PU-70 from Fangchuan Company, and the ketone resin is CF-120 from Crefu Company Aldehyde and ketone resins and additives are selected from DuPont's IA10 coupling agent, environmentally friendly triester citrate, and Clariant's 3620 polyethylene micropowder wax.

[0024] A kind of preparation method of gravure ester-soluble golden ink, the weight percent of its raw material is:

[0025] 6 parts of transparent yellow 4400T (DIC), 11 parts of electroplated silver 41-0010 (Ciba), 25 parts of ester-soluble polyurethane resin liquid PU70 (Fangchuan), 4 parts of aldehyde and ketone resin CF120 (Crifu), polyethylene wax 3620 ( Clariant) 1.5 parts, IA10 (DuPont) 0.5 parts, 2 parts of triester citrate, 18 parts of ethyl acetate, 32 parts of n-propyl acetate.

[0026] The prepa...

Embodiment 2

[0034] The difference from Example 1 is that the weight percent of its raw materials is: 7 parts of transparent yellow 4400T (DIC), 8 parts of electroplated silver 41-0010 (Ciba), 28 parts of ester-soluble polyurethane resin liquid PU70 (Arakawa), aldehyde Ketone resin CF120 (Coriver) 2 parts, polyethylene wax 3620 (Clariant) 0.3 parts, IA10 (DuPont) 0.2 parts, triester citrate 0.5 parts, ethyl acetate 20 parts, n-propyl acetate 30 parts.

[0035] The preparation method process of above-mentioned gravure ester-soluble golden ink is as follows:

[0036] (1) Use the following components by weight: 6 parts of ethyl acetate, 2 parts of aldehyde and ketone resin, stir and dissolve to form a polyketone solution;

[0037] (2) Weigh the following components by weight: 28 parts of ester-soluble polyurethane liquid, 7 parts of transparent yellow, 0.3 parts of polyethylene wax, 0.2 parts of A-10 coupling agent, 0.5 parts of triester citrate, n-propyl acetate Add 20 parts into the above ...

Embodiment 3

[0043] The difference from Example 1 is that the weight percent of its raw materials is: 8 parts of transparent yellow 4400T (DIC), 13 parts of electroplated silver 41-0010 (Ciba), 30 parts of ester-soluble polyurethane resin liquid PU70 (Fangchuan), aldehyde Ketone resin CF120 (Coriver) 5 parts, polyethylene wax 3620 (Clariant) 2 parts, IA10 (DuPont) 0.5 parts, triester citrate 2.5 parts, ethyl acetate 16 parts, n-propyl acetate 23 parts.

[0044] The preparation method process of above-mentioned gravure ester-soluble golden ink is as follows:

[0045] (1) Use the following components by weight: 6 parts of ethyl acetate, 5 parts of aldehyde and ketone resin, stir and dissolve to form a polyketone solution;

[0046] (2) Weigh the following components by weight: 30 parts of ester-soluble polyurethane liquid, 8 parts of 4400T yellow pigment, 1.5 parts of polyethylene wax, 0.5 parts of A-10 coupling agent, 2.5 parts of citrate triester, n-propyl acetate Add 13 parts of ester to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com