Powder coating with imitation anodic oxidation effect and preparation method thereof

A technique imitating anodic oxidation and powder coatings, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems that dyes are easy to lose color, fade, fall off, etc., and achieve excellent decorative effects and strong product stability , Overcome the effect of poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

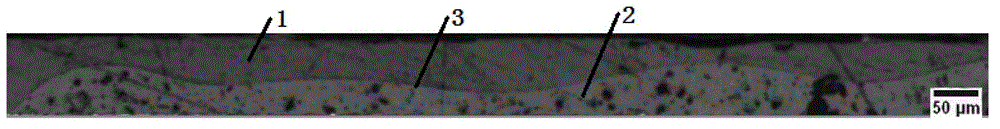

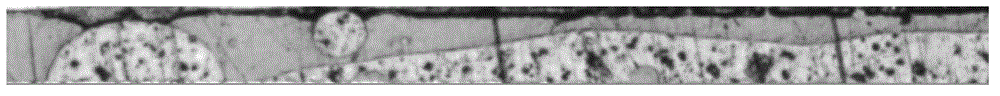

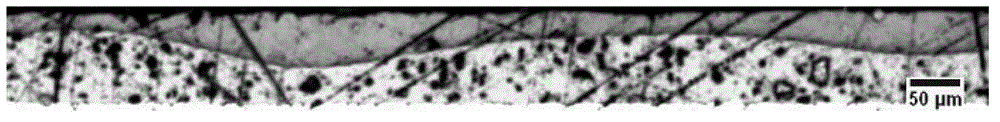

Image

Examples

Embodiment 1

[0067] The powder coating with the effect of imitating anodic oxidation described in this embodiment is obtained by dry mixing the epoxy resin particle system and the fluorocarbon resin particle system at a ratio of parts by weight of 1:1.

[0068] Described epoxy resin particle system is made up of the component of following parts by weight:

[0069] Bisphenol A type epoxy resin E-12 and dicyandiamide curing agent A total of 75 copies;

[0070] Dye Basf Lise Baohong 395 9 parts;

[0071] 4 parts of auxiliary agent A, said auxiliary agent A includes corner coverage modifier 1 part, curing accelerator BASF2-MI1 part, wetting and dispersing agent 1 part, 1 part of flow aid alumina C;

[0072] The fluorocarbon resin particle system consists of the following components by weight:

[0073] 96.5 parts of FEVE resin and isocyanate curing agent Degussa VESTAGON B1530;

[0074] Leveling agent GLP588 1.2 parts;

[0075] 4 parts of auxiliary agent B, said auxiliary agent B incl...

Embodiment 2

[0083] The powder coating with the effect of imitating anodic oxidation described in this embodiment is obtained by dry mixing the epoxy resin particle system and the fluorocarbon resin particle system with a ratio of parts by weight of 6:4.

[0084] Described epoxy resin particle system is made up of the component of following parts by weight:

[0085] A total of 95 parts of bisphenol A epoxy resin NPES-903 and substituted dicyandiamide curing agent (CASAMID710 from THOMAS SWAN);

[0086] Dye Basf Lise Baohei X511 parts;

[0087] 10 parts of auxiliary agent A, said auxiliary agent A includes corner coverage modifier 3 parts, curing accelerator BASF2-MI5 parts, wetting and dispersing agent 1 part, 1 part of flow aid alumina C;

[0088] The fluorocarbon resin particle system consists of the following components by weight:

[0089] FEVE resin and biuret polyisocyanate curing agent 403 90 copies in total;

[0090] Leveling agent PV88 1.5 parts;

[0091] 2 parts of auxil...

Embodiment 3

[0098] The powder coating with imitation anodic oxidation effect described in this embodiment is obtained by dry mixing an epoxy resin particle system and a fluorocarbon resin particle system at a ratio of parts by weight of 4:6.

[0099] Described epoxy resin particle system is made up of the component of following parts by weight:

[0100] A total of 40 parts of bisphenol A epoxy resin (NPES-903) and hydrazide (ADH) curing agent;

[0101] Dye Clariant Yellow 3G 20 parts;

[0102] 1 part of auxiliary agent A, said auxiliary agent A includes corner coverage modifier 0.3 parts, curing accelerator BASF2-MI0.2 parts, wetting and dispersing agent 0.1 part, flow aid alumina C0.4 part;

[0103] The fluorocarbon resin particle system consists of the following components by weight:

[0104] 99.3 parts of FEVE resin and biuret polyisocyanate curing agent;

[0105] Leveling agent P200 0.7 parts;

[0106] 10 parts of auxiliary agent B, said auxiliary agent B includes 3 parts of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com