Brass gold color dyeing solution and preparation method thereof as well as method for dyeing gold color on brass

A technology for dyeing gold water and brass, applied in the direction of metal material coating process, etc., can solve the problem of not being able to form a stable, uniform and beautiful coating, and achieve the effects of low cost, reduced resource loss, and reduced environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

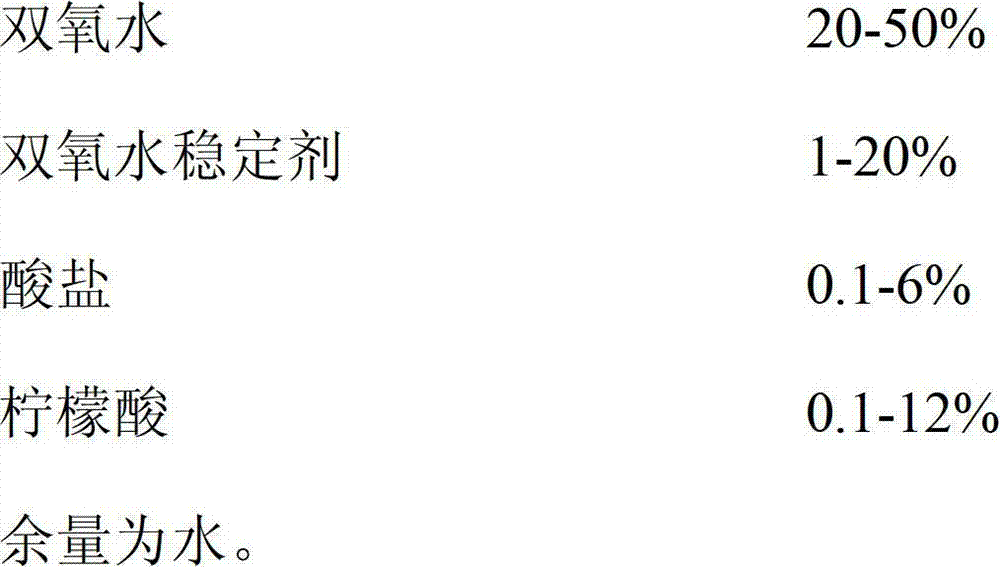

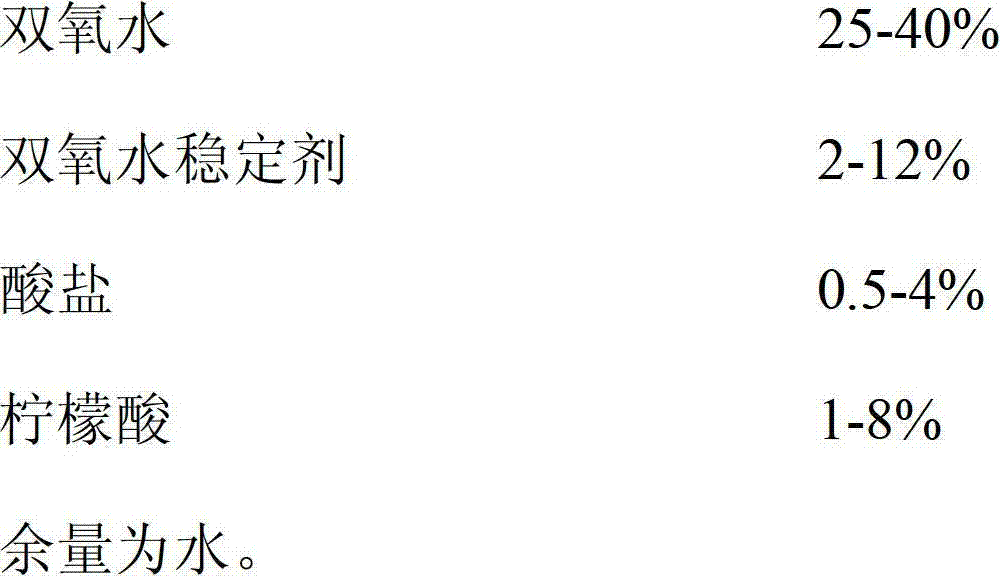

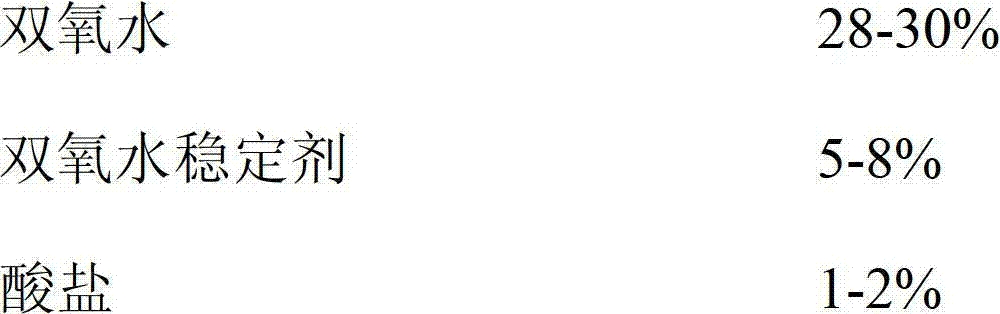

Method used

Image

Examples

Embodiment 1

[0039] First drop in 23.84 parts by weight of water, then drop in 0.1 parts by weight of citric acid, 0.05 parts by weight of sodium hydrogen sulfate, 0.05 parts by weight of sodium hydrogen phosphate, 20 parts by weight of hydrogen peroxide stabilizer, 50 parts by weight of hydrogen peroxide under stirring, and finally add 5.96 parts by weight of Parts of water were stirred for 10 minutes to obtain gold-dyed brass water, then 300ml of gold-dyed brass water was taken, and 700ml of water was added to prepare the gold-dyed brass water of 300ml / L.

[0040] The brass plate is degreased, washed with water, activated with sulfuric acid, washed with water, dyed with the prepared 300ml / L brass gold dyeing water at 100°C for 10 seconds, then washed with water, dried, sprayed and sealed to obtain 18K gold-colored brass .

Embodiment 2

[0042] First drop in 12.2 parts by weight of water, then drop in 12 parts by weight of citric acid, 4.2 parts by weight of sodium bisulfate, 1.8 parts by weight of potassium bicarbonate, 1 part by weight of hydrogen peroxide stabilizer, 20 parts by weight of hydrogen peroxide under stirring, and finally add 48.8 parts by weight of Parts of water were stirred for 5 minutes to obtain gold-dyed brass water, then 100ml of gold-dyed brass water was taken, and 900ml of water was added to prepare the gold-dyed brass water of 100ml / L.

[0043] The brass plate is degreased, washed with water, activated with sulfuric acid, washed with water, dyed with the prepared 100ml / L brass gold dyeing water at 30°C for 100 seconds, then washed with water, dried, sprayed and sealed to obtain 18K gold-colored brass .

Embodiment 3

[0045] First drop in 18 parts by weight of water, then drop in 8 parts by weight of citric acid, 2.4 parts by weight of potassium bisulfate, 1.6 parts by weight of potassium bicarbonate, 12 parts by weight of hydrogen peroxide stabilizer, 40 parts by weight of hydrogen peroxide under stirring, and finally add 18 parts by weight of Parts of water were stirred for 12 minutes to obtain gold-dyed brass water, then 200ml of gold-dyed brass water was taken, and 800ml of water was added to prepare the gold-dyed brass water of 200ml / L.

[0046]The brass plate is degreased, washed with water, activated with sulfuric acid, washed with water, dyed with the prepared 200ml / L brass gold dyeing water at 5°C for 120 seconds, then washed with water, dried, sprayed and sealed to obtain 24K gold-colored brass .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com