Waterborne undercoat-topcoat integrated paint applied to type-25 passenger trains

A water-based, bottom-surface technology, applied in the field of paint making, can solve the problems that water-based paints are not as good as oil-based paints, and achieve the effects of fast drying speed, high hardness and good anti-sagging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The raw materials are as follows:

[0028] Epoxy resin (128 or 828 Taiwan Hongchang or Jiangsu Sanmu)

[0029] Methoxy poly(EO / PO)-2-propylamine (207 Chongqing Maitu)

[0030] Methylsiloxane (methyltriethoxysilane, methyltrimethoxysilane, dimethyldimethoxysilane, dimethyldiethoxysilane, hexamethyldisiloxane, phenyl trimethoxysilane Ethoxysilane, etc., one of Guangzhou Shuangtao)

[0031] Defoamer (2550 BASF)

[0032] Neutralizer (DMAE Hymings Chemical)

[0033] Mixed solvent (ethylene glycol monobutyl ether: ethylene glycol: acetone = 40: 40: 20)

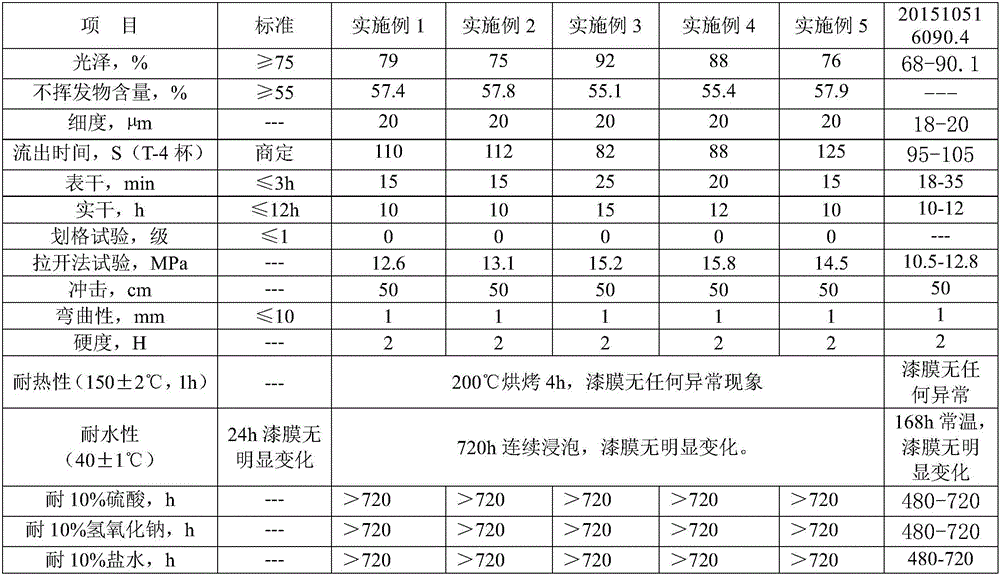

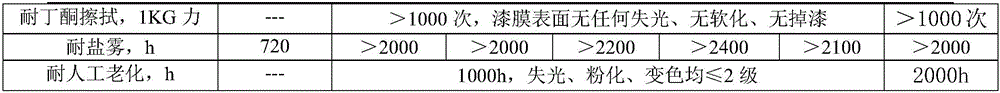

[0034] Table 1: Example 1-Example 3 Waterborne Epoxy Resin Emulsion Formula Proportion

[0035] raw material name

Example 1

Example 2

Example 3

Epoxy resin / %

40

42

45

Methylsiloxane

10

8

5

Methoxypoly(EO / PO)-2-propylamine / %

4.3

5.1

6.7

Mixed solvent / %

4

6

7

Defoamer / %

0.2

0.1

0.3

Neutralizer / %

0.5

0.8

1

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com